minimum floor space for 8x12 c&p?

I’m considering picking up a motorized 8x12 c&p but have only a very specific area for it in my garage where I can set it up.

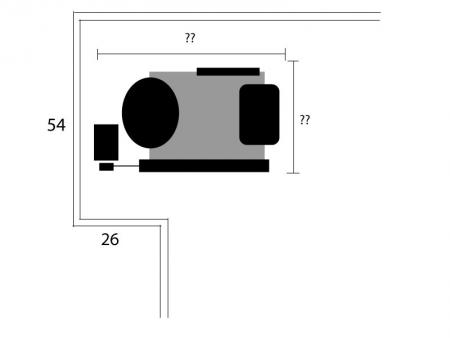

is there anyone who can tell me if this space would work? (see image below)

another option would be for me to build a thin base of 2x6 layered with a perpendicular base of 2x6 with casters so that if I did need to pull the press out of the nook to access the sides or rear I could do that without too much hassle.

i could easy build some sort of locking mechanism to keep the press from moving all over the place while in operation by drilling into the concrete slab and installing an anchor that will hold the whole thing in place.

during normal operation do you need to have access to the sides and back of the press?

lastly, the motor is and press are mounted on the floor, can the motor be mounted closer to the press to reduce the depth of the setup from front to back? obviously i’d need to find a new belt the correct size.

i should have measured it when i was looking at it yesterday but i didnt really think of it.

thanks.

available space

The approx. footprint of mine is 48D x 38W x 48T.

Don’t forget you need to leave room behind the press for it to open — bed back, roller arms swinging.

Bob

My 8 x 12 C&P press all the way open is 48” front to back. I removed the motor it came with and put on a treadle.

Side to side it is about 32”. I don’t have that drive pulley on the right that other presses might. This does not take into account the feed board swing out. The space between the red tool box and the orange press on the right is 42”.

I have plenty of room to reach all of the oiling points.

The 26” wall seem like it could make it a tight squeeze but maybe you can pull it out from the back wall for it to not be too much of a problem.

Connie

little press.jpg

so you can ‘downgrade’ to a manually operated press by installing a treadle? hmmm. i’ll have to look into that. i mean, a motor is a time and labor saver but something about really going old school with this equipment is pretty cool.

so it seems that with the 54” space I have I’d be left with about 8” on each side of the press.

the press would be set back into the recess so if I left 8 inches in the back and fully extended the press is 48” there would be about 30” of the flywheel side of the press exposed.

since i didn’t have much else to do I banged out a quick 3d rendering of the possible layout.

the pine cart actually holds my Poco No2 proofing press which I didn’t feel like creating in 3d.

the 8x12 c&p is traced from the parts manual and scaled to the size people have mentioned here.

it actually looks like it might be ok in that space.

I didn’t really measure that back wall but ultimately I plan to put a marble top composing table next to the 3/4 cabinet but since i don’t have the measurements on that i left it out for now..

the proofing press cart is on wheels so that would be moved out of the way when working with either press and put back in place when not in use.

seems like it just might work.

lastly… with this going on a concrete slab in the garage I assume it’s still going to need to be bolted to the floor?

anyone else have one of these on concrete?

what did you do?

k.

everything but the back wall width is pretty much to scale.

the press sticks out a bit which is good. I'll just need to install a worklight over top of it.

When you are talking a quick 3D rendering what does that mean? How long did it take? That’s great! I love to do 2D plans to see what will fit where. It really helps.

The treadle conversion is no problem if you have the correct shaft.

took about an hour or so. it’s an old 3d program i used to use alot (caligari truespace) so i can get around in it pretty quick. most everything is just squares. all measurements are in inches so i just input those numbers.

it took longer to find a side view illustration of the press then it did to trace it in illustrator, import it into 3d program and extrude it to give it width. I left off the flywheel and just made the object as wide as the press plus the flywheel so it looks a little wider than normal.

what’s the width of the press without the flywheel?

plus, i’m watching cartoons on and off. haha.

Probably about 4 inches less. Then you would be at the throw off lever. But mine is an old style. It might be different if it’s a new style. What type is the one you are looking at buying?

As far as bolting it down from your Letpress post? Not necessary. The press is so heavy it won’t walk if that’s your concern. They also are relatively easy to move if you need to if you put it on skids. (See above picture.)

We sort of beveled the bottom of the fronts of the skids so the press starts up on the pipes for moving easier.

i actually didn’t know how to tell old and new apart until last night so i’m not sure which it is.

right now the press is bolted to the floor along with the motor so I think I’ll need to put it on some type of platform or skid at least initially to run it with the motor.

i’ll hold off drilling into the floor initially.

it’ll be a couple of weeks before i have the press in the garage so we’ll see how it works out.

thanks again for the info.

I think it would be a mistake to stick your press back into a corner like you are planning. You need to have access al the way around the press for oiling, cleaning and maintenance. In my last shop I had a 10” x 15” that only had 15 inches on the throw-wheel side, and I deeply regretted it when I had to climb in sideways to reach the oil holes at the base of the press and the motor. Allotting 8” on each side of the press is not enough space in which to operate. You won’t even be able to extend your feed board. Reasonable access to the sides of a platen press would be closer to 2 feet. I would instead use the space for your rolling worktable or a type stand. Sticking 1800 lbs into a tight corner is going to make you very unhappy.

Paul

Paul

Paul, maybe he’s a bit thinner than some of the older guys and can squeeze in there. Not saying that you are old and large, my c&p only has about 8 inches on the flywheel side, if i eat any more ice cream i won’t be able to oil my press. Paul right you should put a type cabinet in there, or something you don’t have to squeeze behind to oil. Good Luck Dick G.

I agree with Paul.

Thin or not it just seems too jammed into the corner. Put the type cabinet in there and put the C&P out on the wall. I can see doing this if there is NO OTHER OPTION, but not if there is another option.

Also nicer when you are printing on it to have some breathing room. You often need to have some place to put paper and the like while you are printing.

thanks, great feedback.

the type cabinets in the nook might be a better idea honestly. my biggest concern initially was coming out too far from that back wall. It’s a 2 car garage and I need about 5-7ft from the wall to pull the cars in and close the door with enough room to walk around the back of the cars.

Since the depth of the press is 4 ft it would probably work well for me to put the back of it against the back wall.

Does anyone have measurements for a full size hamilton cabinet and a 3/4 cabinet? I wonder if I can fit both of them side by side in that alcove. i can give it a cool name like ‘typecase corner’.

The full-size Hamilton Cabinet is 37” wide at top and the 2/3-size is 27”. Of course the top extends about 3/4” beyond the cabinet on both sides, but still would not fit in 54” width if trimmed to cabinet size.

awww poop. well maybe this isn’t a 3/4 cabinet then. it’s quite a bit shorter than the full size cabinet and I don’t recall it being even half as wide as the big hamilton

that’s what I get for not measuring things. :)

Perhaps it is a materials cabinet, with narrower cases with equal-sized spaces for borders and dingbats. It appears if it is 17” or narrower, you may have a fit.

If you stick with letterpress, you will soon find that the cars won’t fit into the garage, and all the empty spaces you think you have now will not be. The tight corner will be the least of your worries.

Paul

I recently brought home what I thought was a 1/2 sized Hamilton cabinet. Looked and looked and couldn’t find any sort of typecase that fit the size of this one, or any other designated size other than 2/3. It had the Hamilton logo plate on the top front and a little serial number plate. I finally looked in my 1923 ATF catalog and found nothing like it in the type cabinet section. I started looking further and found it few pages earlier in the catalog. Mystery solved! It is a No.4 bookbinder cabinet. It has 18 cases and is about 21 inches square at the base.

The number in the catalog corresponds to how many cases the cabinet held. Each case I think is about 16 3/4 wide. It had evenly sized compartments that were removed. There were 49 per case, 7 x 7. It is quite a bit shorter than the full sized cabinet. It’s awfully cute. :o)

Maybe this is what you have?

well, I’m definately going to have to lose the full size arcade cabinet and seriously thin out some stuff I’ve been holding onto for no apparent reason. :)

the one thing my wife WON’T have though is a reduction in the halloween decorations.

I’m going to have to come up with some sort of multi-level storage solution on the right side of the garage, maybe even install some pull down stairs to use the space above the garage for the zombies.

my wife is expecting at least another 2-3 animated zombies in the yard this year and possibly a new cemetary sign spanning the driveway since the one in these photos was only built for the year.

http://good-times.webshots.com/photo/2582675960102617907LqIkwu

i KNEW i should have built an addition on the garage before laying out the stone patio behind it. haha.

here’s what I have (or WILL have) in a week or so.

the single hamilton full size hamilton outlined in red,

obviously the C&P OS press, and all the cabinets/furniture in the one image.

if anyone can give me a point of reference for size I might be able to figure out the height, width and depth of those stacked cabinets without measuring them (since they’re a few hrs away)

all of this, minus the coffee cup.

the full size hamilton cabinet

and of course this 8x12

You are going to have so much fun!

Keith, just park the cars in the driveway where they belong and fill the garage with printing treasures. Dick G.

haha, yeah. I’m lucky that my better half is even considering me setting up a shop in the garage. I was doing some work on the house and had my miter saw, table saw, etc occupying the garage for a couple of weeks and i never heard the end of how her poor truck was left to suffer in the night cold. haha.

happy wife, happy life.

Otherwise known as a press widow.

The one thing that I haven’t seen mentioned here is training - have you run a C&P in the past? If not, you should definitely take a class or two before even thinking about running a motor-driven platen press. These presses can and will bite! Start with a treadle and work your way up to a motor. I also agree with the suggestions to give yourself some room all the way around the press, it makes things so much easier! I also concur with those suggesting that you park the car in the driveway - my girlfriend bought me my first press (my C&P) for my birthday and it took all of 9 months to fill up most of the garage with printing equipment. She is now thinking that she created a letterpress monster!

Have fun and be safe!

Steve

Paper Stone Printing

Steve Nartowicz

P.O. Box 137

Chesterfield MA 01012

413-834-0930

www.paperstoneprinting.com

http://www.etsy.com/shop/paperstoneprinting

shop1.jpg

Paperstoneprinting:

That’s not anywhere near “full” : < )).

You’re right Mike, I can still walk through the center - nowhere near enough room for a car though!

re: training.

I have not run a platen press before but the current owner will walk me through it’s operation and provide any and all training I ask him for. He’s been printing in the same place for over 30 years. Great guy. I will be sure to take advantage of any knowledge he shares.

famous last words…

i’ll just do this as a hobby with a couple of things here and there.

Steve, you need a few more trips to Letterpress Things, there is way tooo much room in your garage. My wife always says no more equipment, she says if anything happens to me she won’t know what to do with my junk, i just tell her to paint mooring on the stuff and call the yacht club. Keith tell your wife she don’t need a big pickup, buy her one of those little cars, that should give you room for a press or two and maybe a rack of type. These job presses will hurt you, pick the printers brain and learn what you can, Good Luck Dick G.

Dick

You’re right, I definitely need more trips to John Barretts! After I picked up the Vandercook in May (a ‘free’ press, the final cost was just under a grand!) I signed an agreement with my girlfriend not to buy any more presses or accessories until September 1st. My mind has been constantly wandering thinking about what I will get next!

Keith, you are lucky to have the printer to talk to, there are also great resources online, here and other sites. Definitely take advantage of any help you can get.

Steve

Steve, i have a friend in Dorchester, MA who is down sizing his shop, lots of letterpress stuff, if interested let me know and i’ll get you his number. Dick G.

dick.. keith wants wood type, cheap. lol.

(but don’t we all)

Dick

Hmmm, I have a signed contract with my girlfriend - would he hold anything until September 1st?? :)

(also raising my hand for the cheap wood type)

Steve

dickg- I’m in Cambridge, what stuff does your friend have?

Steve, he burned all his wood type in his wood stove!!!!! he thought it wasn’t worth anything. The shop belonged to his dad and mom, he took it over in the 1960’s, his son works with him now. I really don’t know exactly what he has i know there is a poco proof press no. 0, a gas ludlow and a electric ludlow, galleys of forms (some i think his mother set in hand type back in the 1960’s) I will ask him if he wants me to post his name and will post if its ok with him. Dick G.

My grandfather burned all his wood type too! He told me he took great pleasure in it.

I wonder what I would have found if I’d had the chance to get it before it went up in smoke…

Daniel Morris

The Arm Letterpress

Brooklyn, NY

the printer I’m getting my press from was telling me how the magnesium cuts he was burning gave off a nice blue flame.

i died a little inside that day. haha.

dick.

i know Dennis Couch on here is really looking for a poco proofing press. not sure if MA is too far for him though.

Keith, I gave Dennis the info. I worked for a company that made rubber dies for printing on corrugated boxes, we used a lot of 1/4” magnesium dies, some were mounted on wood. One day the company decided to throw out a bunch of them, my boss took a lot of them home. We found out later that he thought he would throw a bunch of them in his fire place, bad idea, a river of liquid magnesium came running out of the fireplace (on fire) he almost burned his house down. Water won’t put out the fire,it makes it worse. Not good to try to burn mag dies. Dick G.

Milk and toast, my friend in Dorcherter is Royal Print, Dave Collins, his phone is 1-617-825-2270, he has lots of stuff, good luck, Dick G.

change of plans.. looks like my wife is going to let all this stuff in the house and actually wants to learn how to use it all.

i just knew she’d think it was cool when she saw it all. lol

the only drawback.. it’s going down the basement.

the good thing about that is it won’t be in the garage which mean.. no 100 degree summers and -10 degree winters. ;)

the only way down is through the house, 6 steps to a landing, 90 degree right turn, 8-12 steps to the basement.

the stairwell is about 36-40 inches wide if I recall.

I’ve gotten 5 full size arcade machines, a 12 foot bar top and a 13 foot skeeball machine down there.. I’m pretty confident we’ll get this stuff down there.

i might cut a few 2x4s and just reinforce the stairs and landing a little.. just in case. :)

I plan to lay 3/4 inch plywood down the center of the stairs the same width as the skids under the press.

with a couple of guys we’ll let gravity do most of the work as we let the press slide down the ‘ramps’ while controlling it’s momentum with loading straps, etc.

seems like a good enogh plan. lol

this should be interesting.

Sounds like fun! Take pictures to share!