Uneven Inking on Magnesium Plate

Hi all,

I am in desperate need of advice. I have printed with the same magnesium plate two weeks ago on my Heidelberg Platen 10 x 15.

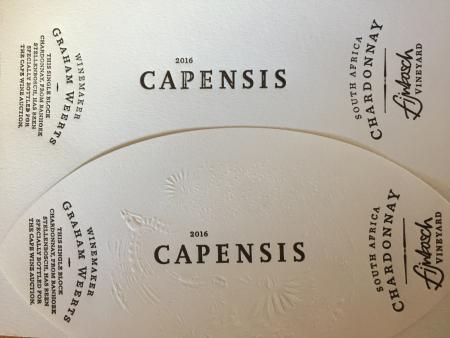

I had no problems on the first run, but with the second run the plate doesn’t want to ink properly on the same raised lettering area as per the attached.

Here’s what I have done to date:

I adjusted the roller height accordingly. I have now re inked the press, replaced packing, moved the plate from the one side of the base to the other and the same problem keeps happening….

I must mention it is pretty hot here in Cape Town South Africa - not sure if that can play a role around 30Celsius

Any advise will be greatly appreciated….

Lise

IMG_9365.jpg

IMG_9364.jpg

Two potential culprits could be:

1. A film on the surface left from washing-up the plate from previous inking. If there is a film of something which tends to hold moisture, it will reject the ink film. If relative humidity is high, along with the temperatures, the plate surface may be harboring moisture. Clean with a not too volatile solvent like mineral spirits or kerosene.

2. If the top of the raised surface still has the etching resist on it, blue or red in color, it may have a similar effect. You can remove this topcoat with a very volatile solvent like MEK or toluene.

John Henry

Cedar Creek Press

Hot can cause ink to thin reduceing it’s tack value. Try adding a tack increaser to the ink. With ink that has thinned due to heat any roller contamination will cause greater issues. Hand wipe all rollers to insure any cleaning compounds are gone.

Take a look at the word “CAPENSIS” with a printer’s loupe of at least 8 power (or an equivalent magnifying glass).

https://www.amazon.ca/s/?ie=UTF8&keywords=printers+loupe&tag=msncahydra-...

When you look at the uninked areas of the letters, where you are having the problem, what do you see? Are there signs of a coating there, as per John Henry’s point number 2 above?

The uninked areas on the plate are so pronounced that it almost looks like those areas are depressed (although I doubt it). Are they depressed?

Judging by the ink on the plate, your rollers appear to be set well.

I’m hoping that John Henry’s suggestion of cleaning the plate with a strong, fast drying solvent will solve the problem. If you can’t get MEK or Toluene easily, you may be able to get Acetone - that may work as well. Use suitable gloves and eye protection.

I’m assuming your rollers are rubber, not “composition.” If they were composition, that could be your problem in the heat and humidity.

Your picture of the magnesium plate indicates that either the type is supposed to be an outline font or the face of some of the letters has collapsed.

Which is it?

Thank you for the all the comments and feedback.

@John - I will clean the plate with mineral spirits - if that doesn’t work - Acetone. We don’t have MEK or toluene around here.

@Western411 - can you suggest a brand name for a tack increaser - I have never worked with this and not even sure what to ask for.

@Geoffrey - I also thought the letters are depressed… called the plate maker but he assured me that it’s precisely 1,6mm raised. I am going to check with magnifying glass.

Yes, rubber rollers.

@2001fred -The type is suppose to be solid not outlined - looks like letters have collapsed.

I will check in and feedback soonest! But first its off to the DIY store for Acetone… and a magnifying glass

Thanks again! Would have been lost without all the great advise.

1 hard hit, either a double sheet or more, can ruin a mag die. they are Very soft, and often the flat areas depress more than the perimeters.

I think I recall that with zinc plates, some colours of inks can if left for a long time actually re-act with the zinc. Vaseline wipe before storage was the remedy. I wonder if magnesium

can react with any of our pigment chemistry? I know for sure that in the days of best quality half-tones on copper, four colour process sets costing a lot of money, they were sometimes given a light electroplating of chromium to allow a

long term storage (and subsequent re-use) and to prevent chemistry reactions. Only in the top shops of course.

Hi all,

So it looks like the letters have collapsed. After cleaning the plate with Acetone and checking under a magnifying glass I have come to the conclusion that it is the plate….

Thanks for all the advice.

Lise

Schwartzletterpress

Possible solution for this issue; place some thin tape on the back of the plate under the area where the letters were collapsed. Lay the plate face up on a clean flat surface. Put a different magnesium plate of the same thickness face down next to damaged plate and another on the other side. Using the 2 upside down plates as bearers wrap a flat sanding block with the finest emory paper you can get and very gently sand the surface of the collapsed letters flat. Leave the tape on the back and see if that will print. Might save you the time and cost of a new plate, might be print too bold.

LSD, the exact same thing happened to

me two months ago.

I sent a picture that looked just like yours to my plate maker and they remade the plate, no questions asked.

Magnesium plates should hold up for a long time.

Jon/Mpls

If the defective letters have hollow centers, where did the metal go, which was in the centers? It doesn’t look like the metal got squashed out of the letters, which would have made the letters wider. So, the only other possibility I can think of is that the metal was etched out of the letters during the plate etching process. If that is the case, why would it have happened? The resist (light sensitive coating which protects the metal during the etching process) must have somehow broken down and allowed the etching solution to get to the metal and etch away the centers of those letters.

I’d like to see the negative which exposed the plate. Maybe it was not completely transparent in the image areas. Maybe there was some density in the image areas, which blocked enough light to keep the resist from becoming completely “hardened” and resistant to the etching solution, and that allowed the solution to get to the metal and etch away the middle parts of the letters.

Another thing about the plate which I thought was strange, is that the entire floor of the plate was routed. Usually only a few areas of the floor are routed, where there may have been some isolated high spots. Why did they do that? Was there not enough relief on the plate, and they did that to try to salvage it? Even though I have been in printing for a long time, I have never printed to achieve deep relief on thick paper, so is this common with plates to print deep relief?

This is one of the hazards of deep impression with wood-mounted blocks of any kind. I suspect there was a soft spot in the wood under the collapsed letters, or the wood was not a good hardwood (I believe photoengravers used to use something like maple blocks — poplar would not be strong enough). I bet if you got the plate remade on a solid magnesium base it would be OK, but better a zinc or even copper die on steel patent base.

Bob

don’t know what packing you use for your setup LSD but if this issue reoccurs, you might be able to add some protection for your plate by using the kind of rubber pad they use in an offset press or the thin silicone pad they use as baking sheets for your packing. The pad can take the added pressure of a double feed and your plate can survive. Of course it wouldn’t work if your setup requires hard packing

Thanks everyone appreciate the comments.

magnesium is a Very soft metal. it is damaged easily. I would highly recommend going to copper.

I believe there is little difference in hardness between copper and magnesium when alloyed to produce rolled plate materials. In fact using some hardness test methods, you will find magnesium the harder of the two. One great difference is in the brittleness of the plates. Magnesium is easily damaged by fracturing, so small elements are quite easily lost of not properly supported by a good shoulder.

John Henry

formerly a photoengraver.

i respect your experience jhenry. I am simply commenting from mine. magnesium for dies, in this part of the world is much softer than copper or brass. easily damaged by a missed sheet or double sheets. Add to that now, mag is a “flammable metal” and keeping much of it around, raises the eyebrows of insurance agents, it is not really worth it. there used to be a substantial cost saving with mag. Not so much anymore. Copper, being easily recyclable , is a better bet.

just back from machine shop. yes on a sunday. with brass measuring the hardest, copper was 15 pts less. Magnesium was 25 pts less. the scale used was set up for steel so exact numbers could not be scaled.