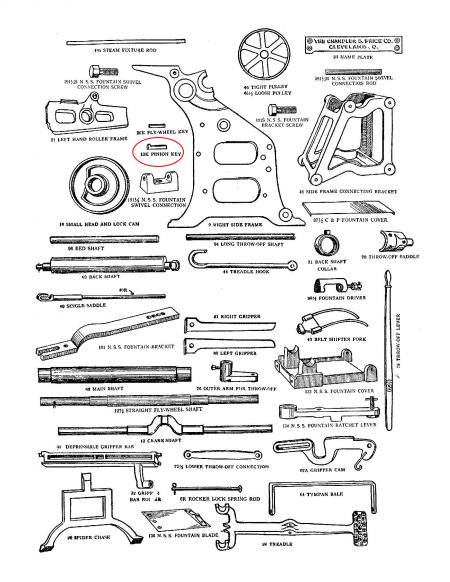

Pinion key, New style 8X12 C&P

Hello Everyone,

I have been gifted a 8x12 new style C&P and I am in the process of getting it ready to be moved. I have read in previous discussions about removing the flywheel and crank shaft in one piece, last night I removed the treadle, ink disc and feed tables. I removed the casing on the left side that covers the two gears and located the pinion key.

I am having a lot of trouble tying to get the pinion key out it’s in there in pretty tight, I tried to tap it out with no luck. It’s pretty awkward trying to get leverage to knock out the key and I also dont want to risk damaging the teeth on the small gear or cracking off the key in the gear. If anyone has advice/experience in getting the key out it would be greatly appreciated!

I’ve attached pictures for reference and forgive me if I used the wrong name for a part. C&P’s are new to me, I own and was trained on a windmill haha!

Cheers,

Lindsey

Key copy.jpg

IMG_7134.jpg

Someone else may have a better suggestion, but I recently tore down my 10x15 C&P to move it. Personally, I took a hammer, and hooked the claw of it behind that shoulder on the key, and smacked the top of the hammer several times to pull back on the key. Took 3 or 4 good hits and it popped right out.

Driving the pinion gear IN may loosen the key; penetrating lubricant could help. Sometimes a wedge driven between gear and gib head may work. Heating the pinion gear with a torch so it expands is a more extreme method.

First, saturate with Liquid Wrench :).

Second, use a ball-peen hammer, not a nailing hammer (which has a hardened face).

After that, I’d use a 6”+ piece of wood between the key and hammer so you can stay on the other side of the gear.

And if the keyway extends to the end of the shaft, you should be able to use a drift punch* to push the key out from there (I don’t have a press handy to look at).

*a small bolt, large nail, or even a hardwood dowel, might do. Almost anything that isn’t hardened.

z!

I was faced with a similar problem and figured out a way to deal with it. Fortunately, I had a friend that had just the right item to cannibalize, a timing gear from an old car.

We had to make two adjustments. We opened the center diameter of the hole using a lathe and cut a slot on the edge of the hole to accommodate the pinion key.

I was then able to slip the gear over the shaft and use a gear puller kit to gently pry the key out. It worked like a charm. Thought I had a video, but I think the pix will work.

IMG_0951.jpg

timinggear2.jpg

IMG_0885.jpg

That Gizmo is a gear Puller, Harbor Freight or Northern tool for El cheapo.

Or as zbang said, use liquid wrench and soak it, than place a small prybar behind the hook and rock it back and forth and they pop out like a charm

When I disassembled my two C & P’s last year, I used a small steel wedge slipped flush against the gear between the gear and the nub on the key. A little gentle tapping on the wedge and it slipped right out. I was showed this by an older machine repairman and it worked quite nicely. Then after removing the key the gear came off without a problem.

The key is known as a ‘gib key’… they have a little taper so that when you position the small gear on the shaft, you tap the key into the gear and it locks the gear in position.

The way I removed them, back in the day, is to Insert a cold chisel (and necessary shims) between the Side face of the small gear and the Key tab….. then tap he chisel to loosen the key, Shouldn’t take much….then withdraw the key from the gear and keyway.

The key must be removed to the outside, right side of the press.

Hope this helps

Best

The key is known as a ‘gib key’… they have a little taper so that when you position the small gear on the shaft, you tap the key into the gear and it locks the gear in position.

The way I removed them, back in the day, is to Insert a cold chisel (and necessary shims) between the Side face of the small gear and the Key tab….. then tap he chisel to loosen the key, Shouldn’t take much….then withdraw the key from the gear and keyway.

The key must be removed to the outside, right side of the press.

Hope this helps

Best

If you attempt to use a puller to pull the gear off of the shaft with the key still in place, you will

Likely pull the small gear (pinion gear) farther up on the taper of the gib key… and make it more difficult to remove the key.

Absolutely, the gear puller without something to pull the “gib key” will create a bigger problem.

That’s why I made the plate to slip over the gib key.

s