Platen Jammed Shut on Heidelberg GT

Hi Everyone,

Yesterday I was printing some fairly heavy stock (12x18) at impression level 3 with normal packing and with register guides (i.e., not commercial register). I was using a large Boxcar base 12x17 (just thought I’d mention that - might not be particularly relevant).

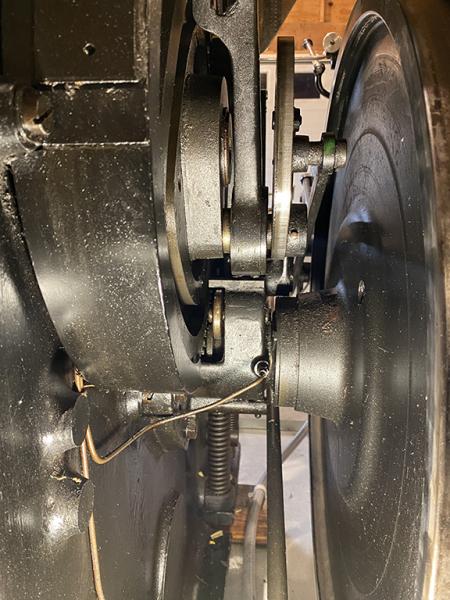

Unfortunately, the ink turned out to be quite tacky and — hard as it is to believe — the cardstock adhered to the three form rollers and “folded up”/got mangled right before the impression was made. The swinging platen is now completely stuck/jammed against the form. The belt slipped off and I cut the power to to the press immediately. It’s impossible to move the GT impression lever - doesn’t move the platen even a thousandth of an inch.

I managed to get the three form rollers off the press and removed the paper tables as well as the impression lever’s stop plate (GT1720) and guide piece (GT1712) for ease of access.

There are some posts and videos on this issue - as so many other things, it’s not the first time it’s happened in Heidelberg history - but they don’t seem directly applicable to the Heidelberg GT model. I don’t believe it’s an oiling issue and the shearing bolt (GT1724) is intact. I’ve even seen an image where someone used a long metal bar/crowbar lodged into the hole behind the impression throwoff lever handle (GT1701) - which seems a little too draconian.

I’ve included some visuals of the present state of affairss. Does anyone have any ideas? I was thinking of looking behind the flywheel to see if there’s a way to “unhitch”/unjam it that way.

Best,

C

view_side.jpg

view_front.jpg

view_platenjam.jpg

view_flywheel.jpg

I’ve never had this happen with my GT (which I no longer have). I noticed the impression lever is lowered, is the hex screw loosened all the way? Also, if you can knock out the shearing bolt, it seems like that would loosen it up. Good luck.

Hi Dennis,

That was my first thought, too, actually. The shear collar is intact and slides right out when untightened - of course the lever then drops. It didn’t affect the jam.

But the incomparable Frank Underwood had a good suggestion, which was to insert a thin screwdriver under the small disk (the safety catch) behind the flywheel. I’ll try that tomorrow - as I took the opporunity to repaint a number of things ;-) I had to take off my motor for access and one thing took the next…

I have a manual from 1974, which — unlike a much earlier one I have — has a GT section. It is some 10 years older than my model, so some of the directions don’t quite apply. Anyway, much like Frank’s suggestion, here is what it suggests on page 105 in case someone experiences something similar:

TURNING BACK THE SWINGING PLATEN - IN CASE OF EMERGENCY ONLY

It may happen by some incident or accident that the press will stick on impression while neither the swinging platen can be moved any further nor can the impression lever be shifted. If in this case a re-adjustment of the clutch (see page 101) does not help, it becomes necessary to turn back the swinging platen.

For this purpose the white painted safety catch is to be slightly lifted from underneath by a screw driver. After a few attempts to move

the flywheel, it can be turned backward, that is in reverse to the normal direction so that the swinging platen is released from the forme.

**By no means should the swinging platen be moved more than 3/8 ” or at the most 7/8” (1 to 2 cm) back from the forme, otherwise this would involve the risk of blocking and damaging the gripper mechanism.**

Such damage would preclude the processing of register work and, should it occur, a qualified fitter should be called to carry out the resultant, necessary repair work.

It would be best to move back the swinging platen only so far as would make it possible to disengage the impression lever. Afterwards the machine can again run in forward direction without impression.

With the Original Heidelberg 10×15”, the pressman can help himself by loosening the 6 bolts with which the end disc at the back of the machine is fastened (see illustrations on page 103). Thus the pressure is released and the impression lever can be disengaged.

Ah, to be a 10×15er - the world is truly their oyster! I’ll report back if and when I succeed!

Best,

Christian

I would have attached some images, but there seems to be an issue with uploading images right now…

Frank’s method worked. With the clutch engaged, one person rocks the flywheel back and forth ever so slightly as your mate shoves or wiggles a long-shafted (9-10”) thin screwdriver under the white catch wheel. Once the platen opens the tiniest bit, you release the impression (press it down), and then jog the flywheel until the platen opens up. Phew.