Ink Issues

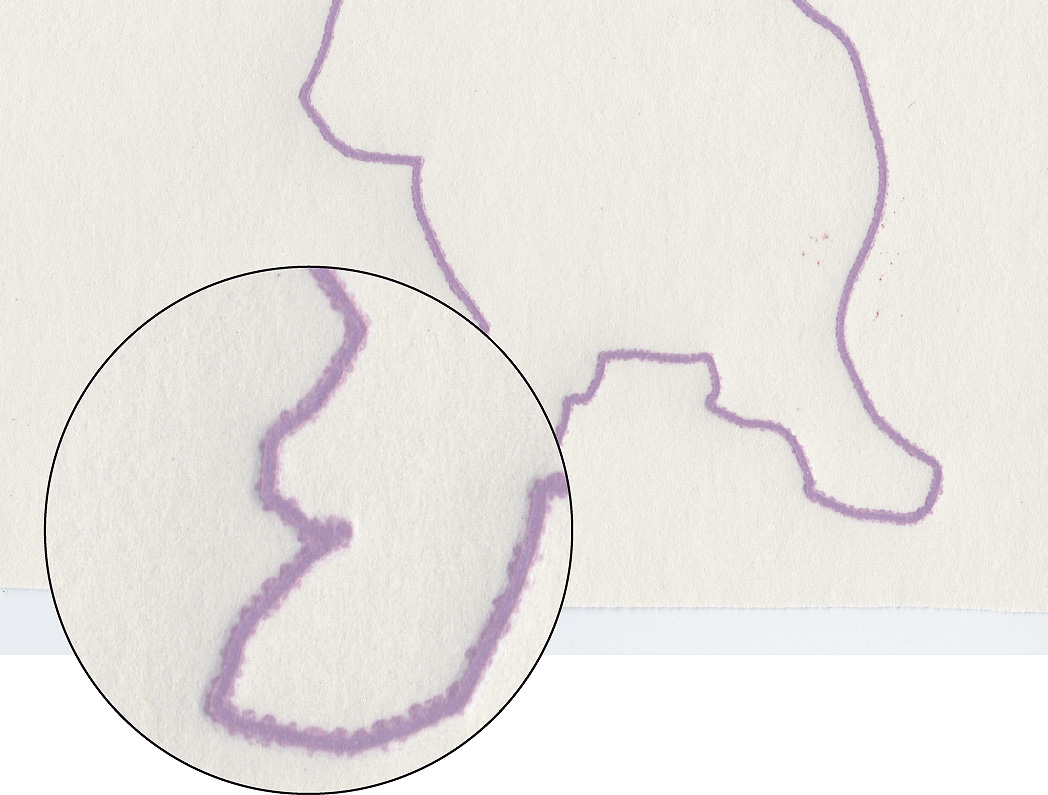

Hey Experts. I’m hoping to get some guidance about what is going on here with my ink. I’m running polymer plate/boxcar base on a Pilot tabletop press. There are always so many variables in my letterpress printing and I always make adjustments as I go. I’m striving to get some sort of consistency in what to expect. Here is my latest issue per my photo. Splotchy ink. Not crisp like I can often get. Could it be too much ink on my rollers? Rollers too close to plate? Too much packing? Unleveled platen? The ink issue is slightly worse towards the bottom of my chase. Any thoughts?

some possibilities are too much ink or oil on the rollers. try less ink on clean rollers to start. :)

It looks like either you are using too much ink or the rollers need to be raised. Or both!

Try starting out with much less ink than is called for and see if it’s still giving you similar results. If it looks crisp, add a bit more and see how it looks. If the print looks good with a small amount of ink, then you are probably over-inking.

If even with smaller ink quantities the printing looks fuzzy, then your rollers are probably too low. Try putting tape along the rails to raise them.

Also, when checking, don’t just pull one impression…pull at least five or so and then check. This will give you more of an idea of how your printing will look during the run.

Brad

Vertallee Letterpress

Amy:

Look at the plate after inking and see if there is ink on the sides (shoulders) of the image lines. If there is a difference in how far down the shoulder the ink is being deposited between the upper image and the lower, you might assume that the rollers are set closer at the bottom than at the top. Perhaps the lockup of the base is tipped or the roller tracks vary from top to bottom.

Take a straight edge and check the lockup by placing the straightedge diagonally across the back of the chase from ear to ear and see if you see light under the base at the lower edges.

If you do, the furniture you are usign to lock the base in may not be square or something.

Tape on the rails will cure the other problem if it exists.

Are the rollers “pinned” to the trucks? If the rollers spin freely, they can skid on the lower edge of an image and cause something similar to the results you are getting. If the image were a bit wider, you could see this more readily.

My guess would be too much ink.

One thing to do when you are in this midst of this situation is to take your ink knife and scrape along the ink disk (while rollers are down, obviously) to remove any excess ink. Scrape with the knife until you can’t remove any more ink. Then pull the chase, wipe down the polymer and make a few pulls on the press to distribute the ink remaining on the rollers onto the ink disk. Chances are there is more ink on the rollers than you would imagine. Once this is done just replace the chase and see how that works.

Thanks for all the great help people. I will use less ink from now on. :)

jhenry, my rollers are pinned, so that’s not the problem. I’m going to check my lockup next. I have two chases for this press and when I place them on my desk they do not lie flat. If I press on one corner the other corner pops up a bit. This might be my issue. I’ve always assumed my desk wasn’t level. It’s very old.

It would be great if this was just an ink amount issue, but I suspect I have a larger problem than that. I probably did have way too much ink, but I get a different imprint on the top than I do at the bottom. There is something else happening, too.

Amy,

Did you solve your problem with the rollers shifting to the left? Perhaps the two issues are related and Jhenry’s suggestion of a “slide” makes sense.

http://www.briarpress.org/5922

I ask because I am having a similar ‘roller shifting to the left’ issue with my Kelsey 6x10. I believe this is because my roller trucks (relatively new as yours are) keep sliding out of their grooves. On my press, if the roller trucks are out of their grooves there is a tendency for the rollers to sllde across the type, as opposed to properly rolling over it, with the result being a slurry print. If your rollers are still shifting, they could be wiping the polymer plate.

Trying pulling your lever a few times without the chase in and see if your roller trucks remain firmly seated.

Drew

Drew,

I did “solve” my roller issues. Well, I added some washers to the outside of the trucks which keeps the rollers aligned on the rails. I’m going to try to rotate my saddles at some point, per the recommendations on my other post, to see if that eliminates the need for the washers.

I don’t think that my rollers are sliding on the type. Next time I’m on press I will watch more closely. It maybe a contributing factor.