Wir-o-binding

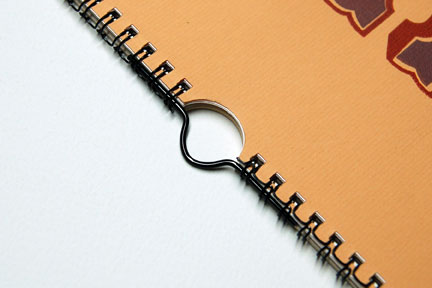

We want to get a wire binding machine (3:1). We have a calendar project and we want to do the binding like the attached image. The wire binding is in two sections with that bent wire to hang the calendar from inserted between the two sections.

Any one know what you call that mechanism for hanging the calendar and where you might get them. I’ve done a pretty thorough search online but just don’t see them or any reference to them. This one is actually a bit heavy. I’d like to find a thinner wire for the hooking part.

Thanks for any help you can offer.

101113-wir-o-bind-w-hook.jpg

Over here we just call them “hangers,” and they’re stocked by the same suppliers that stock wire-o.

You’ll need a seperate machine to do the thumb-tab punch for the hanger.

As it turns out that’s pretty much what we call them over here.

Seems like an obvious word to search for. If I Googled “calendar hangers” I got a bunch of exactly what I need.

Thanks, Nicolas.

By the way - looking at your picture again - here’s something to watch out for when you’re binding your own calendars.

Contrary to your picture, we usually bind our wire-o so that the join lies between the backing board and the last page of the calendar (or book, or whatever).

One achieves this by inserting the stack over the wire with the back page moved to the front, then closing the wire and moving the back page to the back again.

It’s more aesthetically pleasing because you can’t see the join/close and also it doesn’t move around when handling. I think, also, in the case of using a greyboard/chipboard backing it keeps pages from falling out at the join (if not joined very tight) because the board is so thick.

Nicolas

Just to finish this discussion off, we finished the calendar project.

The problem sometimes is that you need to actually go through the process in order to see all of the subtle things that can go wrong.

Thanks to the suggestions we received on Briar Press we bought the ‘hangers’. The slight problem with that was that none of the sites ever said how much of a bend there was in the hangers. Our calendar was printed on 100# Mohawk Superfine (15 sheets) so we needed at least 7/16” or 1/2” wires. Well, the hanger will fall through because the diameter of the wire binding is too large to lock the hanger in.

Next time we’ll use the hangers.

Also there is a totally separate issue with the ‘thumb’ hole you need so that the hanger will have room to spin around as you change months. Drilling the paper seems like the easiest way to do this but I couldn’t find a paper drill that was maybe 1” in diameter. If you look at the photo above it might even need to be larger than that. I guess we could diecut it but the size of the calendar was 11” x 17” and while our C&P 10 x 15 would surely handle it diecutting them is a bit difficult and with as much trouble as doing the printing for the calendars was we really didn’t want to be messing them up with diecutting. I saw that you could buy a handpunch for that notch, but it was $190 and we were needing to do 7,500 calendar sheets.

Anyone know if such a thing exists. Largest I could find was 1/2”.

Anyway that project is done.

Anyone got a Heidelberg cylinder press they would even remotely consider selling?

It’d be labor intensive, but…. You could maybe do it by hand with a rubber mallet and a gouge, with the paper clamped in place on a nice piece of wood or cutting mat. You’d do every calender individually.

Look for sculptor’s “U” profile Gouges, probably to be found somewhere like a wood carving supplier.

And there’s this on ebay:

http://cgi.ebay.com/Heidelberg-KSB-15-3-4-X-22-1-2-Cylinder-Letterpress-/130415095913?pt=LH_DefaultDomain_0&hash=item1e5d587069#ht_500wt_922