some success

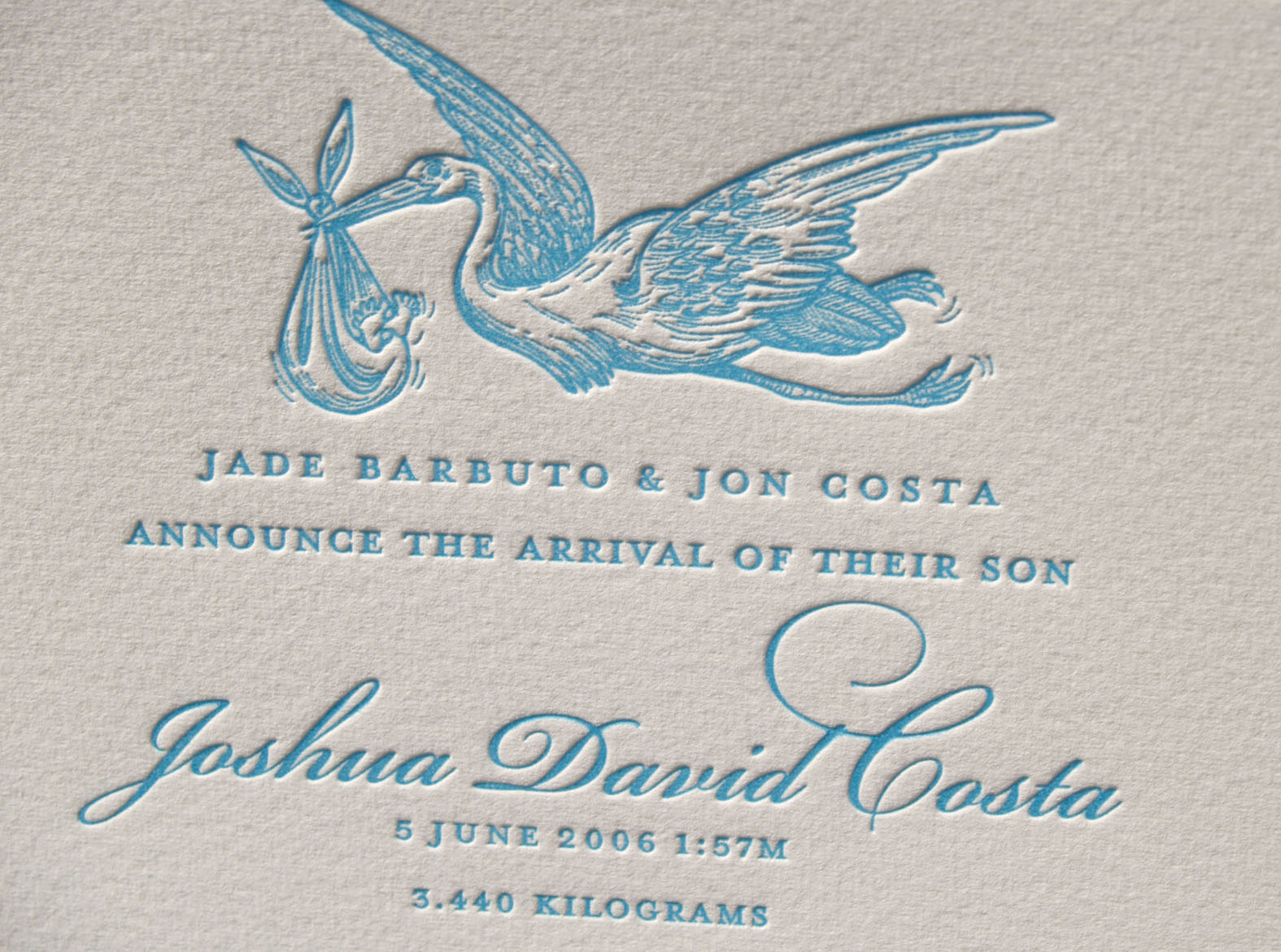

I just wanted to show you all the success I have had today. I have spent much time getting to this point, I have spent heaps of time reading and learning from everyone and so I just wanted to share this with you. I know the amount of impression has brought much debate to this website - but I like it - sorry :).

In this print I have an even colour and impression through slowing making adustments, considering my make ready and building up my impression.

Thank you everyone, I am sure i will continue to draw on your help - very soon :).

Meaghan

Make sure you keep your rails clean. When oiling your rollers on the ends sometimes a tiny bit of oil will get on the rails and this will prevent you from getting good ink transfer from form roller to form. What will happen is the form roller can slide across the form. I use a small bit of Powder Rosin or baby powder on the rails after cleaning, this keeps the trucks maintaining good friction on the rails. The powder was recommended by my good friend Vivian at 9SpotMonk.

Great to hear your doing well with printing.

Casey

iLP

Congratulations Meaghan,

Beautiful piece. I wouldn’t do any apologizing, in the end one can know all there is to know about history, theory, colors, design and all. What some don’t know including myself is: we don’t know what we don’t know.

Those things that are expressed here as gospel are just the beginning point to set you on your journey. I’m sure that if the first printers would have been happy if that is what they had gotten.

Like saying there is only one recipe for making bread, not so. Keep up the good work.

That looks nice! Good job. I’m sure your clients will be happy.

Thank you everyone.

Also this is not a real job - I don’t think I am ready for that yet. I am just building up some samples for a portfolio - so I hope to be in business soon :).

Stay tuned…

What type of plates are you using, photopolymer, zinc or magnesium?

This is with a boxcar base and deep relief photopolymer (KF152) I couldn’t be happier with it. Hope this helps?? :).

Nice job Meaghan, your client should be thrilled.

Hi Meaghan,

Looks beautiful. What type of press do you use?

My press is a Heidelberg T Platen (10x15) with the black ball and from the serial number it is around 1948, so pretty old and made before any improvements were made - but I love it and I am getting to know it and all the quirks :).

HI Meaghan…lovely work, what a thrill to have your press working so well - I am in Aus too and am wondering if you can share where you found your press? Cheers, Julie

Updated. Well… what an adventure this has been. I would love to share probably depends what state you are in? I have made many contacts on my journey so far. I am in Victoria and depending on what press you are after I can give you some leads.

Look forward to hearing from you.

Oh and I bought my press on ebay - took a bit of a chance on it. Grays online seem to have my press (heidelberg t platen) on auction quite a bit.

m

Thanks for your prompt reply. I am in NSW, but would be willing to travel to find the right opportunity. Is the Heidelberg T Platen the same as the Windmill? I have always dreamed of owning a Windmill, but am still doing my research to make sure I could find people out here to service if required. Have you had to have any maintenance done to your press? Julie

Yes it’s a windmil and mine is a 10x15. I would look at:

www.graysonline.com.au

I have seen some really good ones there.

Heidelberg should be able to help you with servicing and parts or know someone who can:

http://www.au.heidelberg.com/www/html/en/startPage

I have had my press looked at by a tech. The biggest thing he did was making sure the gripper arms were straight and one had a crack in it. Now it runs like a dream as this machine was built to last.

Perhaps try getting something newer one with a red knob.

And can I just say that while the press itself was afffordable everything that came after that has been $$$$$$$. Don’t let that put you off just be ready for it…

Have you tried contacting a local printing museum?

2 days ago I found out that a printing museum not far from here has a whole collection of old presses, including a windmill, and I am trying to get in touch with them daily as I am keen to investigate. Was moving the press a major hassle for you??

Updated. The press is around 1200kgs. I took a whole day to move it as the press was about 4 hours away from me. I decided to do it myself and wow what an adventure. I could have used a moving/frieght company to do it for me at around $1000 and doing it myself cost around $300.

I hired a small truck and drove it to the press. A crane moved it onto the press. A couple of blokes tied it down for me - that’s when I went ‘oh shit’ how am I going to get this home (4 hours away) what if the press moves or worse! Anyway the drove was slow and we made it. A forklift got the press off the truck, drove it up my driveway and a couple of pallet jacks and large metal pipes lowered it to the ground.

I was so worried it would fall and smash to the ground…

When you get one you will have to check the power source as it might need 3 phase so a converter or new motor or something

Thank you for the insight. I think I would have a mild heart attack on the day I move a press. Good for you for being so resourceful. I spoke with a man recently who has a one phase motor windmill for $500 and a three phase motor windmill for $4,500….unfortunately it is about 10 hours away, so its hard to go and investigate (I must say I am super curious what a $500 windmill looks like?? He assures me it is in complete working order.) Do you know anything about the one phase vs three phase motor? Your last commented suggested the one phase is inadequate?

sooo cool. Congrats and your first print worth bragging about ;)

3 phase and 1 is all about the power you have available and both will operate the press just fine and the same. As I am not sure where you plane to set up the machine you probably don’t have 3 phase power readily available at your powerpoints in your home? Because most presses are in use in factories they are fitted with a 3 phase motor which is what most factories use.

I would be very sceptical about a $500 press!

It could be covered in rust. The platen could be damaged, what about the rollers and gripper arms!!

You can always email me if you have any questions of photos of presses or anything… :).

I know, it seems too good to be true (usually is) but apparently there is no rust etc, it just has not been used for a while - I realize that could create problems too. I am currently getting some more information and pics. Thanks for the power info, makes sense, and yes it would be in my home studio. I really appreciate all your help, thank you.

Sometimes a press that hasn’t been used in a while is a blessing (not overly used!)

When I got my press it had not been used in over 20 years.. but it was stored inside. And amazingly the rollers & trucks on it are pretty good (but the extra ones in the box however — not salvageable..)

But I would say short of going to look at it and making it move (& noting it will need oil ect) theres no really good way to make sure its in good condition.

Maybe they can send you photos? and some close ups too! A serial number can be used to track how old it is (with in a range.)

Yes, I have requested some pics. Is there a specific kind of oil one should use for this equipment??

I use a light weight machine oil (way oil) I bought a small bottle (4 ounces I think) from Ace Hardware — next time I want to get a bigger container or get a machine shop to sell or donate some to me!

I know a lot of people use car type oil but my father works with all types of machines for a living and he really recommended a lighter weight oil than 30w. And its also what Chandler and Price recommends in the manual for my press. Im not familiar with windmills so you might look around on the letpress list or briarpress.

Angela

Thanks for the tips. Is your C&P the press you got that hadnt been used for 20 yrs? I am investigating a recent lead for a C&P press not too far from me. I dont have too many details as yet, but I’m doing some C&P homework anyway. How do you find the press, is it easy to work with?

Updated. Yes my C&P sat in a garage for 20 years and in storage a school for I don’t know how long before that.. I really like it but its the only kind of press I had ever watched run before. Very simple to operate.. Lots of people have them so help is available from lots of people!

My C&P is a new style 8x12, I do not have a treadle (though I wish it did!) I have a small 1/4 horse power motor (and I also have a 1/2 horse power but that went way too fast!) A variable speed motor would be nice.. but other than that I really like it. I do not have feeder or an inkwell.. But im okay with that!

Look closely at the rollers & trucks on the press, I got lucky mine are in pretty good shape, new ones are expensive.. I have one truck that doesn’t adjust so I have only been printing with 2 rollers but it has not been an issue. 3 rollers will set you back 300+ dollars so keep that in mind if you are purchasing the press.

Angela

Hi! I just moved a Heidelberg Windmill. We jacked up the windmill and put heavy heavy duty steel pipes (3) under it and rolled it out of a shop, then attached skids to it and then had a Tow truck company come and pull it onto a flat bed trailer by the skids, strapped everything down and then did the reverse at my garage. Really a slick operation. 3 people can do it.

I have also cleaned up a really grimy C&P Oldstyle using Greased Lightning, Vinegar, Lemon juice and WD-40. The best tips I received are using a drill bit to clean out the oil holes and spray WD40 or 3 in 1 oil on all the joints before trying to move anything.

Good luck!