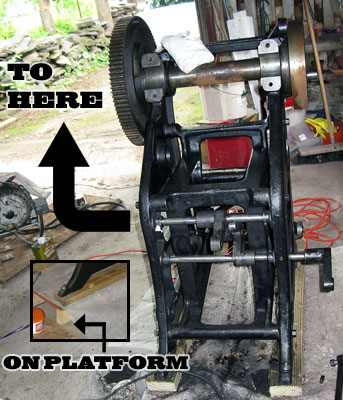

Moving half an 8x12 C&P 15’

Hello! I need to move half (or so) of my 8x12 C&P out of the dark garage and into the sunlit driveway so I can see it to clean it. My family is being unbelievably uncooperative. It can’t be that hard for three able bodied adults (ok-2 have bad backs) to move the thing 15 or so feet? It is on a little platform made of 2x4s which might make things tricky (a pallet jack would be convenient but I don’t have one on hand). Anybody have some quick ‘n easy handy tips? Thanks! -Gilly

(by the way, we intend to round up some more helpers when we actually move it into the shop but it seems silly to get everyone over here just to move it to the driveway and back…)

moving.jpg

You could possibly rent a pallet jack and save yourself a headache.

Or…

I would suggest that one of those trees in the background could be used as an anchor point for a come-along. The press should move reasonably well along flat ground since you have it on that platform.

Or…

You could just get a couple people and rock it side to side and you should be able to get it to move forward. I have managed to move my 8x12 NS a couple of feet on my own using this technique. Yours should be considerably easier since it is partially disassembled.

Hope this helps.

B.

Gilly- beleive me, I know about “unbelievably uncooperative” family members. About the only one of my family who helps out is my wife…. and together we have lugged some awfully heavy pieces of machinery around. We once moved a Kelsey Star letterpress and a Reliant Cutter in the back of an Isuzu pick-up truck in a single load. The poor truck never drove right again.

Since it’s mounted on 2x4s, I’d use a few lengths of heavy pipe as rollers. Or do like dicharry suggested and rent a pallet jack. Just be careful to not dislocate something important whilst trying to lift it.

Wouldn’t it be easier to just rig some more lights in the garage?

Since you don’t have a pallet jack, the platform makes it more difficult, not easier. I’d suggest you get rid of the platform unless you specifically need it for some reason.

What you have doesn’t really weigh a whole lot, but more than you can just lift - so you need something like a small hydraulic jack (a little bottle jack is fine), or a J-bar, or a good lever of some sort. A helper would be nice, but not strictly necessary. Get at least three rollers at least a couple feet long (pipe, tubing, old broom handle, whatever). With the jack or lever, lift one end, put a roller under both of the 2x4s the press is bolted to. If you can, put it towards the center of the press (not way out at the ends of the 2x4s). Do the same with the other end so the press is now on rollers, and you’ll find it will move pretty easily. You may need to make a temporary ramp to roll it down off the platform. Looks like your driveway may be gravel, not concrete - it will roll much easier on scrap plywood or some other smoother surface than gravel. Ask if you have questions!

Dave (the Ink in Tubes guy, moved 9 presses recently)

I tried lighting the garage with a big double halogen worklight but I still couldn’t see very well. I was thinking maybe closing the garage door would help since my eyes wouldn’t be adjusting to the bright light outside… I guess I’m going to have to keep my eye out for a used pallet jack or something, because there isn’t really anywhere to rent one around here. I might be able to find one to borrow… In the mean time I’ll see what I can do to get the thing off the platform. It was put there originally because sometimes spring run-off floods the garage a bit, but since there’s no snow to melt and the ground is no longer frozen it’s unlikely that any flooding would be higher than the 2x4s it’s bolted to, so it doesn’t need to be up there any more.

Thanks! Now off the couch and getting to work…

SIMPLE ( SIMPLE * SIMPLE

Get 3 used STEEL Pipes at any plumbing shop) at least 2-inches in Diameter——leave the press (securely secured) on the 2x4’s as it is now——-get a 2x4 turned on end (3 1/2” side) or get a large pry-bar and put it under the front crossmember of the press and lift——slipping the first pipe under the 2z4’s—-get behind the press and PUSH—-the press will roll forward and place the second pipe under it—

and finally the third——start to roll the press and as the rear pipe rolls out take it around and place it in the front—-if you have two+ people it works like a charm——I’ve moved 50+

presses this way over a 40-year time span—-it REALLY

DOES WORK! Good Luck.

Like Gaslight-Daze said - pipe rollers are wonderful - I would suggest having 5 or 6 if possible, and an accomplice when trying to move it, if only to steady it when it rolls - and on flat driveways, it can get away from you if you’re not careful.

A pallet jack is great - but to work easily, you really want to have a base designed for use with pallet jacks.

Good luck!

Bill

I would take the press off the platform but leave the two 2x4 runners attached to the feet. This will make it much easier to move because you can roll and slide it as necessary over various surfaces and inclines, something you can’t do easily or at all when dealing with four seperate feet.

My 8x12 was disassembled as yours is and I moved it out of a van and onto my front porch, through my front door, and across the length of the carpeted living room using two 3/4” dia. x 24” long iron water pipes. Three pipes would have been easier but I only had two. I did this by myself and it was simple, easy and safe. You my need or want one or two more people depending on any inclines or steps and the type of terrain you have to traverse.

I lifted one end of the press slightly using a length of 2x4 I had laying around for a lever and slid one of the pipes under the two runners. I rolled the press forward so the pipe was just beyond the halfway point. It was then easy to tilt the balanced press back and slip the second pipe under it. I just continued in this way alternating the pipes. To make a turn just work the press around gradually in the direction you want it to go as you roll it forward. Three pipes would have made all this easier with two under the press all the time and the third being moved forward. But it worked fine with just the two.

If you have to go up and/or down steps or from one level to another lay down a couple lengths of 2x6’s as ramps for the runners to slide/roll over. I did this when it came off the van onto the porch. There was a slight downward incline and I didn’t use the pipes at that point since I was by myself but just pulled it down the 2x6’s. It slid easily when I pulled it and at the same time the friction of the wood-on-wood kept it in place until I wanted it to move.

I had a couple of pipe clamps used for woodworking and I took off the clamp portions and used these so I didn’t have to purchase anything. I tend to be frugal and like to use what I have on hand.

Rich

I knew it couldn’t be as hard to move as they were trying to convince me it would be…

Unfortunately I’m leaving tomorrow for a few weeks. I had wanted to get it in the shop before I left. Actually I had wanted to get it in the shop and re-assembled before I left, and originally I had hoped to be printing on it before I left.

At least the rest of it is in the shop now, fresh rubber rollers included, waiting for my return, at which point I will have stocked up on steel (or iron?) pipes, and the larger portion of the press will be triumphantly re-united with the smaller parts, and hopefully I will not have lost any important bolts or anything, and it will all come together and I will have made a large poster of the crushed-fingers-hazard sign to remind me that the C&P is potentially more dangerous than the sweet little Sigwalt, and together we (C&P & me) will produce all sorts of finely printed materials and it will be very satisfying…

s-2589m.gif

And the lion shall lay down with the lamb and the mountains shall be lowered and the valleys raised…

;-)

You’re almost there! But to have to wait a few weeks: Oh, the anticipation!

Rich