Ben Franklin Trim-o-saw parts?

I just acquired a Hammond Ben Franklin Trim-O-Saw and I have a few questions about the saw blade and trimmers. The saw is an older one with serial number 8983. It did not come with a manual.

What size blades does this saw use? It came with a 5 1/2” Comb. “C” blade. Where can I find a new blade for this saw?

Also this saw is missing the cutters that project from the left side of the blade for finishing the cut. Is there a place where I can purchase the missing cutters? If not, does anyone know the specifications for the cutters or have any extra cutters that I can purchase?

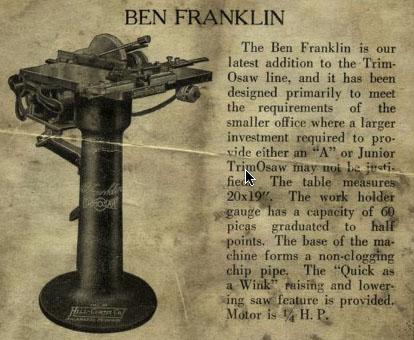

This picture looks like the saw I have, except this is a photo of a Hill-Curtis Co. saw while mine has the name Hammond cast into the bottom of the base and on the name plate.

Thanks

BenFranklinSaw.jpg

This won’t help you find parts, but Daniel Petrzelka has quite a number of Trim-O-Saw and related manuals online at:

http://www.petrzelka.com/Site/Letterpress_Manauls.html

I’ve also scanned a Hill-Curtis manual (predecessors of Hammond) which includes the “Ben Franklin”. It’s at:

http://www.archive.org/details/HillCurtisTrimOSawOperatingInstructions19...

(The image you posted is from the last page of this scan. Glad to see it’s been useful!)

Regards,

David M. MacMillan

www.CircuitousRoot.com

Hammond Ben Franklin Trim-O-Saw is a great saw for the composing room. I used one for many years. The main issue is getting the correct saw blades and trimmers.

Get a carbide blade and trimmers would be unneccessary. Blades for Hammond saws are the most easily found of any printer’s saw. NA Graphics certainly has them, as do others selling sawblades.

In every discussion online regarding the trimmer knives of composing room saws, someone will always make this point (“get a carbide blade and trimmers would be unnecessary”). What I’ve never seen is an explanation of why this is so. As a cutting material, a carbide is simply harder than steel, not more accurate. What is it about carbide sawblades which makes them so accurate?

Regards,

David M. MacMillan

This is a circular argument, but consider what is so coarse about standard sawblades that trimmers are needed? I can say that my first carbide blade gave smoother cuts than the standard blade that came with the saw, but sharpness and tooth count must be considered.

There are many possible tooth shapes and tooth counts, and smoothness of cut will vary among them; different blades were meant for wood, for typemetal, for stereotypes, and there were also all-purpose blades. But a sharp blade will cut smoother and carbide blades stay sharp much, much longer than standard saw blades.

Unfortunately, the last time I had my blade sharpened locally, they altered the original kerf and using it to mortise type requires some additional hand-dressing now. Whenever possible, send the blade to the manufacturer for resharpening.

At any rate, all the sawblades I have seen available now, new, for printer’s saws have been carbide (but then I have looked for Morrison not other brands). I have not seen any new sources of trimmers; I have been told there are modern equivalents, but haven’t found them.

At a visit this Summer to Dave Churchman at his very interesting used printing warehouse in Indianapolis, Indiana, he sold me a trim saw and several extra blades. He also sold me new cutters for the planer function near the center of the blade. As an Industrial Arts teacher who also cuts wood type with a historic pantograph, I am sure they are installed the same way jointer knives are. A dial indicator (expensive) would work the best to be sure the cutters are all the same distance from the blade side and parallel, but you can also use a very clean piece of maple and 20 lb copy paper as cheap feeler gages. The trick is to clamp a long block of wood to the saw body parallel to the blade that will not move. Then you can use an end grain piece of maple to just touch the cutters with the .003 thick paper spacer as a guide. The cutters must be parallel to the block face and blade, and should just touch and move the paper when the blase and arbor is rotated by hand pass the block. The shop teacher in me wants to remind you to please be sure the trim saw is unplugged before doing any work on a blade or cutter and to be sure everything is tight before you make any test cuts. Don’t be in a rush and be prepared to make fine adjustments. It also helps to mark the three access holes with numbers or letters using a sharpie so you can work in 1, 2, 3 or A, B, C order every time.