Putting a 10x15 In A House

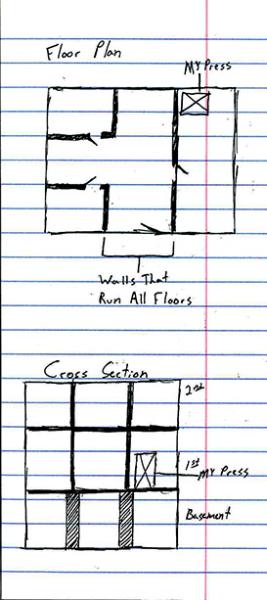

Please see attached image for reference.

I have the option of moving my press from my unheated garage into a heated space attached to an old church. However, I am concerned about the weight of my 10x15 Chandler and Price Craftsman Press on the floor. I will be on the first floor (ground level), but there is a fully functional kitchen space in the basement, located directly under where my press would sit. You can see in my quick drawing of the space that I would locate the press as close to the walls as possible, but I still fear this is not enough.

Any advice is much appreciated!! Thank you

floorplan.jpg

Not too drastic a problem , but not knowing how your buildings are constructed, makes it a little hard to help from this distance. Presumably your construction could be anything from 3/4 inch floor boarding, sitting on 4x2inch up to maybe 9x2inch joists probably spaced at about 18 inches apart. If as your drawing seems to imply, your joists are covering relatively short spans, the first option would seem to be, sit the machine on a steel base that covers at least 3 joists, thereby making every joist take only 1/3 rd of the total weight. If however the joists would seem to be inadequate, the next option would be (possibly) 4 box girders at 3inches square with fish plates top and bottom tight against your walls with 2 cross members (3inch box girders or “H section” R.S.J,s) sat on top, against your joists immediately under your press. You could reasonably expect to support many tons like this with only the loss of 6 inches working space 3x2 twice on your lower level.?????

If the area of the kitchen below would accommodate them, a couple of jack posts under the end of the press away from the basement wall should handle the weight just fine. I guess there is no easy way to determine the size of the floor joists in that area — in an old building they might be pretty substantial. I’d feel more secure with the jack posts.

Bob

Think of it this way. If five men who weighed 250 lbs each stood together in a tight group on the spot where you want to put your press, would they go through the floor? Of course the thickness of the floor board, joist and supporting beams have to be considered. If the church is older than 50 or 60 years, it probably has larger beams because they had plenty of wood back then. Just another way of thinking.

>five men who weighed 250 lbs each

5 x 250 = 1250, but the weight of a 10x15 Craftsman without automatic feeder is quoted as 2,000 pounds in the Western Newspaper Union Catalog No. 53 (2675 pounds with feeder).

Regards,

David M.

www.CircuitousRoot.com

Sorry, I was thinking an 8 x 12 but you get the point. Eight big guys very close together to make the foot print of the press. And then they jump up and down. This forum needs a little humor now and then.

Ya think?

As a former structural engineer, my suggestion would be to hire a structural engineer to do a quick inspection and a few calculations just to be sure. There are way too many assumptions to be made in terms of member depth, spacing, direction, and span not to mention other load which you might be unaware of to be confident in blanket approval. The suggestion of using a steel plate or some other kind of sleeper system perpendicular the existing floor system to distribute the load could be adequate though as well as the least invasive. If the press is already on skids, that might do the job well enough so long as they are oriented correctly, perpendicular to the floor joists.

Even if it is likely okay by itself or with an easy fix, when you are putting someone else’s property at risk as well as your and other people’s safety (working in the kitchen below) it is better to take all the precautions.

Another safety question: Is this space going to be made inaccessible to the public? I certainly wouldn’t want people, kids particularly, to be wandering around and get curious about this great piece of machinery and hurt themselves turning it over and getting caught. A way to lock the press in position could be another alternative.

I have several presses in an old chapel which was part of a convent. The floor in this building was designed to carry a substatial load with parishioners filling the room at times. It was built in 1949, and was built well.

I asked a local architect to come in and inspect the areas where I was going to place the equipment and he indicated that the structure was fine as is, and needed no additional support. It has 2x12 floor joists 16” on center. Even with his recommendations, I did add an additional 4x6 crosswise of the joists held up with jack posts under my Little Giant as I had some concern about the reciprocating action of the bed over time.

It never hurts to be careful, and you might be able to get a feel for the floor structure by removing floor registers on the upper floor or drilling a small hole and running a stiff wire down until it meets the resistance of the ceiling beneath. That would tell you the depth of the floor joists. You might be able to use a stud finder to find out how far apart those joists are spaced.

John Henry

Thank you everyone! I work at an Architectural and Engineering firm, I think I can find someone to help!!

Worth keeping in mind that the weight is YOU and the press.

Also worth remembering that this space is attached and not actually part of the church construction itself, so the way the structure was built might be entirely different.

And the weight of a new series 10 x 15 is 1,500 pounds.

I’d also be worried about the floor that you will be wheeling the press over to get to it’s final resting place.