C&P 8x12 replacement motor

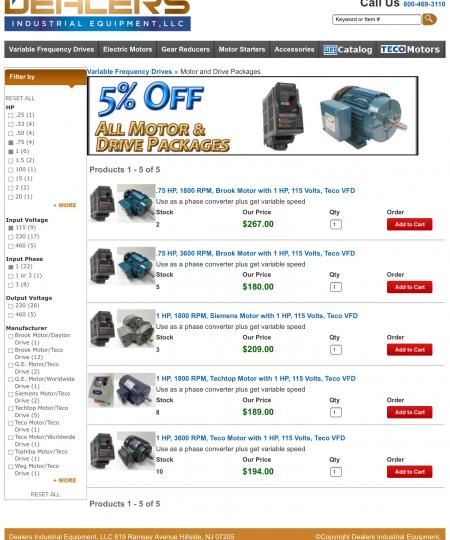

I might have to buy a replacement motor for my C&P 8x12 Old Style. Someone recommended http://dealerselectric.com/motor_drive_packages.asp, but I’m not sure on the specific motor to get. It needs to use regular home electricity. Can someone share their recommendations please?

Thank you

image.jpeg

You probably could go with the first one at the top of the page on the link: a .33 HP, 1800 RPM motor with a 115 volt drive. 115 volts is regular house power (technically house power is 120 volts, but that doesn’t matter here). I ran my 8 X 12 C&P with a 1/6 (.17) HP motor off an old water pump, which was half the power that the 1/3 (.33) HP motor above has.

The smaller C&P presses, when well lubricated and when they don’t have anything wrong with them, turn very easily, so the drive motor doesn’t have to be very big. I think people often put larger motors on them than they really need. As I said, I ran my C&P 8 X 12 with a 1/6 HP motor for many years and never had any trouble. I suppose if you were always printing from plates with a large amount of ink coverage, you might need a bigger motor, but you shouldn’t be doing that anyway. The most amount of ink coverage you should have, should be about 1/4 to 1/3 of the total chase area. In other words, if you were to take all of the area which actually prints, and push it all together into a solid block of print with no white in it, that area should not be more than 1/4 to 1/3 of the total area of the chase. But I’m getting off the subject……

I don’t know how you are driving the press (with a belt to the flywheel, or a belt to a pulley, or friction drive, etc), but it would be better to run the motor with as small a pulley as possible so that it ran at a higher RPM. Ideally, when the press is running at the fastest you would ever want to run it, the motor should be running close to its 1800 RPM top speed.

I will be interested to see the other replies you will get to your query as well.

I just got done setting up my 8x12 C&P Using the .33hp 1200 rpm brook motor and Teco VFD from dealers electric. I mounted the vfd in an enclosure to keep oil and dust out. I also ran a remote start stop and speed control under the delivery board. I am running an 18.75in diameter pulley on the press and a 1.5 in pulley on the motor. If you are running off the flywheel the 1800 rpm motor should be fine.

IMG_1251.JPG

IMG_1250.JPG

IMG_1248.JPG

Thank you very much for the feedback guys.

asblee77, your setup looks great. Thanks for the comments.