Paper Cutter Electrical Advice

Hello Everyone,

I recently purchased a second hand Triumph 6550-A paper cutter, I didn’t find out until after I purchased it that it is a three phase machine. I have it in my small residential studio which is single phase. I called around to local electrical business but I’m getting the run around unfortunately, one company quoted me $12,000 and said I needed a new motor in order to use in my studio…

I’m looking to see if anyone has run into a similar issue or has any experience or advice in this matter, I have researched electrical phase converters but i’m not sure if this is an avenue is the correct one to go down.

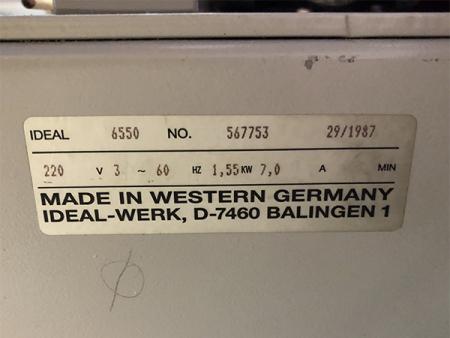

Attached is a photo of the spec sticker on the back of the machine.

Thanks,

Lindsey B

PaperCutter.jpg

technology has came a long way this little teco box can turn your house current to 3 phase for up to 3 hp motor. They can do other things like hook a 12 volt emergency cut off switch to cut all power to machines. There is a few models they come with a book that is impossible to read, I asked for a election that under stood it on Craigs list. He hooked it up in 15 minutes. Your cutter needs to run at 60 there is a digital read out on front. For your set up it will be 2 lines of 110 and ground going in and coming out is 2 lines for 220 you can switch these to reverse direction of motor and one line for center leg of your 3 phase this one must be in correct place on motor.

You would run one of these boxes on each piece of 3 phase equipment mounted in a metal box. not on wall like mine.

CC29E309-120B-46A3-9DC7-493851602DDE.jpeg

I was just curious what kinds of single to three phase converters, rated at seven amps, were out there. Here is the google search I used:

https://www.google.com/search?q=120+vac+single+phase+converter+to+3+phas...

…or… in text:

120 vac single phase converter to 3 phase 220 vac at 7 amp

First, get a new electrician. I have a great one if you are south of the LA area. I had one of those in the 80’s and I find it hard to believe it took that much power, in fact I thought it was 110 20 amp. Find an owners manual for the cutter and or contact Ideal for one. There may also be a sticker in the motor that may give a better idea of what the power needs are. Phase converters work. Sometimes there are different line setups on the motor for different power source ‘s and the vendor may have a electrical diagram better detailing what to do.

Thanks guys for all the advice, I’m located in Newfoundland, Canada. There aren’t many people around here with experience or knowledge with print equipment and even less with letterpress knowledge. Hopefully I’ll get this sorted soon and I wont have to go out of house to cut paper for my windmill.

I’ll make sure to update when I get it running!

This has been discussed here several times, but when I do a search for “VFD” on BriarPress, I just get an internal server error. VFDs are the cheapest and most efficient solution and are programmed for specific conditions. (I say this having a rotary phase converter for a 6 HP motor.)

I’ve run into the 3 phase motor problem a few times. On my Windmill and my guillotine I found it best to swap the motor for a single phase, cost about $250. A rotary converter costs about $1200 and I used one on my Heidelburg and Miehle cylinder presses as the motors can’t be swapped for single phase. In the U.S. there are a lot of boxes like Todd has posted, but not here in Canada. My advise is get a single phase motor, they can be wired 110 or 220 volt, just get the right shaft size for your pulley and a mounting pattern that will fit the cutter.

I think the motor is integrated on those Triumph cutters.

I went through this with a challenge 305. One issue seemed to be that a VFD wouldn’t play nice with the onboard computer of the cutter. Ended up finding a single phase 305 cutter which was great… and coincidentally currently listed for sale in the classifieds if anyone is interested…

Yep. a VDF should only supply a single motor since it’s not a “phase converter”. If there -is- a computer, then it’s probably best to bring out it’s power leads (and it won’t be 3-phase) and just give that 220/240 volts. Handle the motor separately.

Also, the electrician doesn’t need to be familiar with printing equipment specifically, more with industrial machine and woodworking tools.