Masseeley Cutting & Bordering Dies and Cutters

Has any one come across Masseeley Cutters and Dies and more to the point has any one used them? Just wondering if they could be used on a windmill or if there was a special machine.

20230607_195352.jpg

20230607_195435.jpg

Yes there is a special machine a masseeley ticket and showcard machine c.1932, I have one in my shed but I sold my brass type many years ago to a chap who wanted it for a masseeley hot foil, but I did use it with coloured papers and heavy card it cuts the letters out and presses it into the card with a lot of force, I suppose the equivalent today are the leather die cutting hand operated ones on ebay.

I suppose you could use on platen if you mounted on suitable height base with adhesive, I will try upload pictures later,

cheers John

I bought one at auction and it arrived today. Oh my goodness what a heavy weight the press is. I also enjoyed opening a box with it to discover it was an original Masseeley box of type/dies but then the whole box fell apart in my hands! I have retained the rather beautiful handles (and the type!) but the cracked wood has been recycled.

Two things /

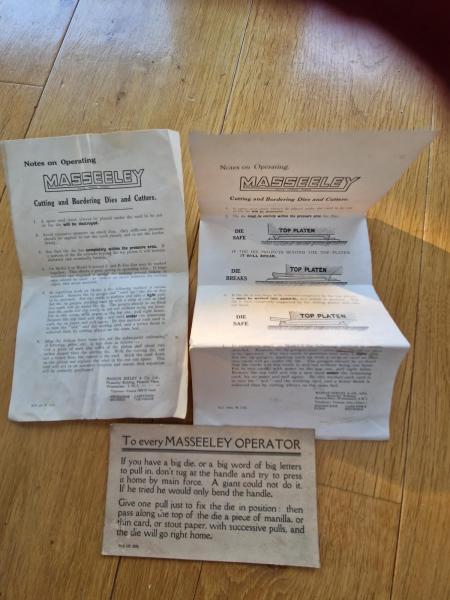

I would LOVE to have a useable scan or pic of that wonderful leaflet if, by any chance, you still have it.

2.Where on the press would I find the model number?

Thanks so much

A few pics from today’s arrival

IMG_3183.jpeg

A long restoration I think’

IMG_3180.jpeg

IMG_3185.jpeg

IMG_3202.jpeg

Hi Simon. Your press appears to be the most popular of the Cold Process machines (sometimes called cutter-crush presses) and probably a Model 9 (or maybe 10). These are among the earliest presses to be made in the UK by Masseeley. They are, as the name suggests, a cold process and do not use electricity. Production continued until well after WW2 with many improvements and modifications. I used Masseeley hot foil presses for a number of years at the BBC, where they churned out thousands of pieces of TV caption material every year.

The original Masseeley presses were German, and imported under licence. Stanley Walpole, the owner of the company, modified and improved them considerably, eventually launching his own version in the UK. The first Cold Process presses date from 1920, with electric hot-foil variants produced from 1930. A purpose-built factory at Tulse Hill (Brixton) made the machines and cast the phosphor bronze types from October 1932. Masseeley’s head office and design studios were in Victoria.

Masseeley supplied everything required for the production of point-of-sale material, including Masseeley branded string and even diamante glitter. The card used in the Cold Process was heavyweight coloured board about 600gsm and available in 60 colours. The boards and the adhesive papers were specially milled for Masson-Seeley. Cutter crush captions were not easy to produce. The coloured papers were gummed and relied to a large extent upon the moisture present in the cardboard base material. If boards were stored near a radiator, or in dry conditions, the loss of the inherent moisture content stopped the process from working properly. Baseboard material was ideally stored in slightly humid conditions before use. I can describe the process separately if others are interested. I have the official Masseeley Cold Process instruction manual c.1940 (14 pages) if you are interested in a copy.

Two types of gummed paper were milled, exclusively for Masseeley, in 36 different colours plus 8 wood-grain effects, gold, silver and bronze. “Standard” and “Instant” gummed paper was supplied. Their use was dictated by the size of the type to be printed.

The last time I saw a cutter crush caption was at John Sanders department store in Ealing Broadway about 40 years ago. When the building was demolished the business relocated to Ruislip in Middlesex and I was delighted to see that as recently as 2019, the cafeteria still had a handful of old cutter-crush captions extolling the virtues of their fine teas and coffees. Alas they are now gone.

Opening1932.JPG

Model9.jpg

By the way, don’t try to use cutter-crush types on a Windmill or any press with heavy impression. You can damage the type - but may also damage the platen of your press. Masseeley instruction manuals have multiple warnings about the damage the type can cause if adequate packing isn’t used on the platen.