Kluge feeding and registration issues (input needed)

So I’m running my first job on a Kluge and have some issues that I’ve run into.

1.) I’m printing on lettra 110lb and for the first color, I used 2 standard metal feet and the job fed great. After I laid down the first color and have some impression on the paper, the metal feet won’t grab the paper and I had to change to the #2 sucker feet. Now these feet grab 2-3 sheets at a time making a mess. How can I make the #2 feet not grab so many sheets or make the metal feet work again.

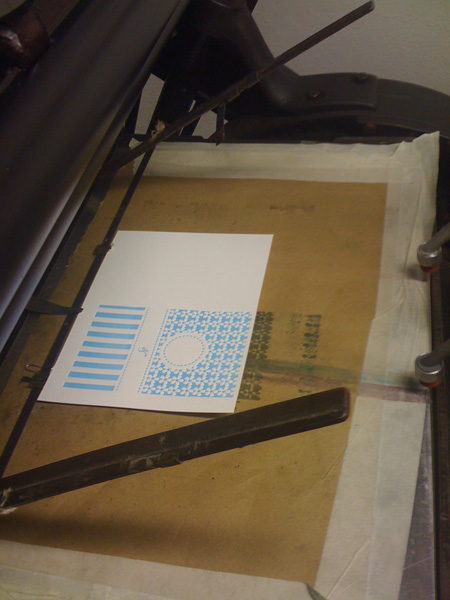

2.) I’m not sure if I did registration properly on the first color run, but all the pages look the same to the eye. I just put two pins at the front that the feeder fed into and when the side clamps came down, they hold the paper in place (pic attached). But now when I go to lay color #2, registration is very inconsistent. Every sheet of paper has #2 color in a different place. How can I make the registration more consistent. More pins, side guides? thx! You can see my print setup in the pic.

photo-prep.jpg

You may have to move the feet around until they can land somewhere on the sheet that hasn’t been printed on, as the dent of the impression is sufficient to break the suction of the suction feet.

If you didn’t use the side register guide on your press (which acts as a push guide such as on a Windmill, it may be difficult to achieve any better side to side register than when the stock was jogged into the feeder magazine. If you are having register “bounce” in the other direction, I will leave that to Kluge pros for how to deal with that.

I don’t see your side guide in the picture. Did you use it on the first pass? If not, registering your second color will be difficult. Mike is right about moving the feet.

I didn’t even realize the machine was missing the side guide until I couldn’t get color 2 to register and read the manual again.

I only printed 30 or so of these pieces as a test so I’ll hunt down a side guide and try again.

Do the rubber bands on the side clamps help too?

It doesn’t look like you have room to use a rubber band. In a pinch I have used fishing line taped to the gripper bars.

Casmit, I f using a string or rubber band to hold a sheet down be sure to walk the press through a cycle to be sure your delivery suckers do not catch the string.

If you need a side guide one source is Suckers.com

find the online catalog : sides guides are on P.4 item 51

Gripper fingers-hold the stock from the side only and clip to the grippers are on p. 3 item 32

without using a side guide tight registration will be difficult. when posioning your delivery suckers try not to hit printed areas as ink can transfer from piece to piece.

Good luck and happy printing

PaulM

Thx Paul. I’ll look through the catalog and see what I can find.

New paper is nice and flat, but after the first color is laid, the paper is kind of warped. I assume flat paper is also critical for proper registration.

Do you just bend it back flat by hand? I noticed that with the paper being slightly warped, registration on the left was able to get in closer to the pins while the right was lifted about 1/4 inch up and couldn’t get quite as snug.

Decurl your paper by hand for the second run.

Kluge’s have a right and left side guide and they have a corresponding cam. The cam is located on the underside of the far right bar your grippers attach to (gear side). It is made of brass.

Here is a crude drawing for location.

photo-prep.jpg

should I be trying to get my paper under the grippers too? or is the tongue hanging off ok.

casmit, it would behoove you to apprentice with a skilled

pressperson. Your lack of experience is a danger to yourself and your machine. The Kluge is a professional machine capable of great work and great damage.

best of luck to you, you will need it. james

casmit, When possible i prefer to keep the stock out from under the grippers, it’s just one more thing to get in the way of feeding and watching what is happening. The grippers will hit side guides an other guides and knock them out of position or damage something, so I use the fingers or string. I also tape the fingers to the gripper so that they don’t accidentily move and crush type(learned the hard way :( )

PaulM

James, I’d love to find someone to teach me the trade, but there aren’t many in Dallas who are willing and work on this same machine. I’m not going to sit around and wait for someone to teach me, so I’ll learn on my own for now by doing, asking questions, and reading. I’d love that opportunity though.

Paul, thanks for the input. I’ll be sure to tape the fingers onto the grippers.

Just an idea of what I’m working on. My first job! I’ll try again when all the pieces are in place.

letterpress.JPG

Looks Great!

Nice work! There has to be someone around Dallas who still runs a Kluge, since they always seem to pop up for sale up there.

If your feeder is still grabbing too many sheets, perhaps you can adjust the air blast or stock elevator to compensate. Be careful though, as it is easy to lock up the feeder if you have your suckers misaligned.

I would love to see a process thread on setting up the feeder on a Kluge, since that’s about the only thing I haven’t done successfully on mine yet!

James Beard

Vrooooom Press

Austin, TX

www.vrooooom.org

Doesn’t Kluge have some videos on u-tube? Dick G.

Dick,

Kluge has some great videos on their EHD/EHF presses, but there doesn’t seem to be a single video or guide to setting up the feeder that includes good pictures or video. I’d like to make one, but it’ll be awhile before I feel comfortable enough to write something on the subject.

FYI, here is a selection of videos that have been helpful. The first is probably my favorite since it’s one of the few Kluge videos that doesn’t show the press moving at full clip. Of course, the Kluge manual is a good source, but its photographic documentation stinks, IMO.

http://www.youtube.com/watch?v=s2SF2oJbVZo

http://www.youtube.com/watch?v=atGg3oHe2Bc

http://www.youtube.com/watch?v=MYzHDp4NZ2g

http://www.youtube.com/watch?v=MwSPyvWpUgg

James Beard

Vrooooom Press

Thx for the videos. I’ve seen all of those except the one on die cutting.

To fix the feeding, I had a couple of things going on. I dropped from 4 to two metal suckers. I put a few pieces of lead under the stack to make it more level, and I moved the suction foot to a part of the paper that wasn’t printed.

It’s feeding great now. The #2 suckers work great on the 220lb, but for this 110lb, the metal suckers are the way to go it seems. That in combination with adjusting the air valve made a huge difference.