Re: Heidelberg: Registration with guides

Today I am trying to print a two colour card and am using the brass gauges for the first time. I did the red ink yesterday which went OK. I got the bottom edge level by adjusting the gauges on the bar without a problem.

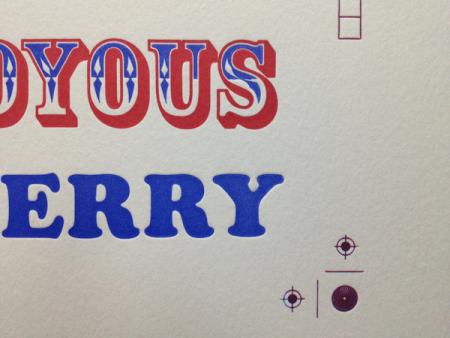

Today I am trying to print the blue ink and I got the registration spot on to start with after a little side gauge adjustment as you can see in the first pic below.

My problem is that when I run the press the registration moves vertically a lot, there is huge inconsistency in the way each sheet feeds onto the gauges. I’m losing far too many of my first ink run to this random rise and fall, its breaking my heart, all the waste.

I’m using a gauge pin on my flywheel side gauge but not on the pump side, is that right?

Any suggestions to help get the paper to land in the same place would really be welcome.

1.jpg

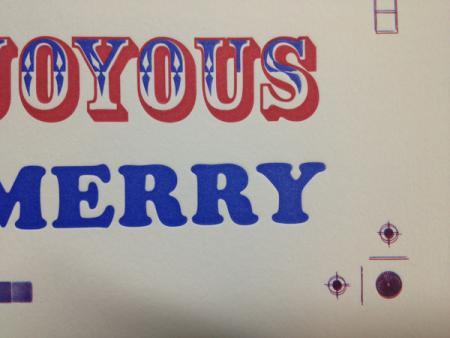

2.jpg

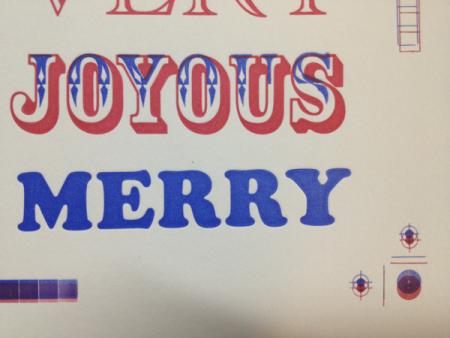

3.jpg

4.jpg

personally I prefer to move the plate base in the chase rather than use the side lay, I have found this to be the cause of many troubles and run it in the fully open position, the bottom lay adjustment is fine, I dont know where you are gripping this sheet a full size photo would help, if it is not dropping down onto the bottom lays try moving the stack slightly over to the right so the sheet has further to drop check the gauge pin is not holding or knocking it back and there is no resistance on the tympan, you can check this by disengaging the lay and moving it by hand with a sheet in it also try without a gauge pin sometimes it works ok without, you could also just check your grippers are clean, hope this helps, if you double print a sheet you can see if the register is ok I just hope it is not your first colour that is out, good luck, John.

You need pins in both of your bottom gauges. Your gripper arm may be pinching the sheet against the platen.

This seems to be something that is induced by speed because it prints in perfect register when I switch off the power and hand roll it through the cycle.

I’m already running the press as slow as I can.

What is the orientation of the sheet… which is your gripper edge? You may be getting bounce from the side gauge.

the side gauge could be adjusted too far left, this will make the sheet bounce back away from the gauge, you might have to back it off and move your base back.

The sheet is going through horizontally and I do have the side gauge well towards the platen, that’s how I got the blue to register with the red in that axis.

‘Side Gauge Bounce’, they don’t mention that in the manual ;-)

So if I back the side gauge off and it corrects this how do I then register the plate again? by moving the base slightly?

The gripper is grabbing the left side of the sheet in the photo below.

Thanks for that suggestion.

5.jpg

OK, I backed off the side gauge completely and ran 8 sheets through perfectly level vertically so I guess that’s what it was.

That kind of defeats the object of having a side gauge at all or perhaps it only happens with stiffer cards or papers? I’m running 300gsm.

Problem now is that my base is hard against the right hand side of the chase so cant just slide it over a mm to get into register again, have to remove and reapply my plate.

Thanks guys that’s one of those ‘learned from experience’ things I would never have worked out on my own, that’s why this forum is so fantastic for beginners like me.

It really is much appreciated….Nick.

you can move that side gauge a little but if its all the way to the left it can cause your sheet to bounce.

Welcome to Tiegel land… You will find that there are a few other things that are not in what is arguably the industry’s best manual. ;)

In the end, it seems that it is all about small moves and process of elimination.

I’ve found that redoing the rubber in the grippers can help. One of our machines needed the side guide to be kept fully to the right to avoid register differences, and this went away after refurbishing the grippers.

Following your advice I repositioned my polymer plate and was able to finnish the run with virtually no registration problems…so thank you for the tip.

That little bouncing issue cost me a lot of paper the last two days, I had been focusing on the gauges and their pins to solve it.

I will look into replacing the rubber on the grippers, thank you Watne.

I’m now putting a few tiny slithers of metal down the right hand side of the chase so that I have some possibility of horizontal adjustment without having to use the side gauge.

Yesterday for want of anything better I used three hacksaw blades from my tool box but it did the trick.

6.jpg

Side Guide Bounce

Fhttp://www.apa-letterpress.com/T%20&%20P%20ARTICLES/Press%20&%20Presswork/Good-bye%20misfeeds.htmllying Dutchman

Mike that looks interesting but I can’t get the link to work, can you repost it possibly?

Ahhhh cracked it:

http://www.apa-letterpress.com/T%20&%20P%20ARTICLES/Press%20&%20Presswor...

Dutchman

http://www.apa-letterpress.com/T%20&%20P%20ARTICLES/Press%20&%20Presswor...

or google Good-bye Misfeeds

Don’t say the words “…cracked it” on this forum! Too many ways to misinterpret ;-)

LOL yes, that was silly, I have so much to learn :-)

‘Side Gauge Bounce’ as relevant as ever, thank you all!