Roller / bed / inking issue – need help!

Hello all!

I’m new to Briar Press and could use your help troubleshooting a printing issue I’m having. I’m using my Cooks Victor press for the first time. It has brand new rollers and trucks. The impression is even and beautiful, so I know the platen is adjusted correctly, but I’m having trouble getting consistent ink coverage. One print is perfectly fine, another is darker in some places and lighter in other places, even if I don’t change a thing! It’s driving me crazy.

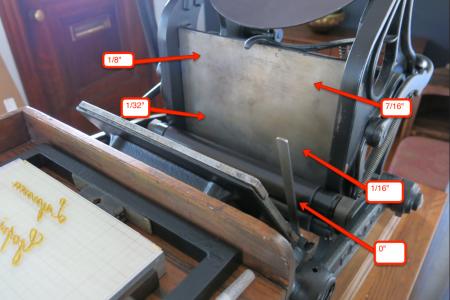

I’ve used a roller gauge to measure the space between the bed and rollers and found the measurements to be very inconsistent. The top left is fine at 1/8”, and I can adjust the top right by adding tape to the right rail, however toward the middle of the press, there isn’t enough ink on the gauge… only 1/32” on the left and 1/16” on the right. At the bottom of the bed, the gauge doesn’t even touch the rollers. I’ve attached an image for reference. Any ideas on how I can address this issue? Do you think this is the cause of the inconsistent inking? Should I add something to the bottom of the bed to bring my chase/base closer to the rollers? Get slightly larger rollers? Add something to the back of my base?

Any suggestions you have to offer are much appreciated!!

Thank you!

Nicki

Roller guage.jpg

maybe a sheet of paper behind your chase. It could be your rollers are old and may be out of round, could be lots of things.

Are the springs/guides which carry the rollers properly lubricated? And just because the rollers and trucks are new it doesn’t mean they are straight and well-centred… I don’t know this particular model - but if the press is refurbished could the bed have been reassembled out of line? If so it would still be possible to adjust the platen to match the bed, but have the whole lot out of kilter. Are the platen adjustment screws set to reasonably equal length?

Are you printing photopolymer? If so the roller setting is critical and typically harder to achieve with a small tabletop press like this. I would first check the roller rail height above the bed, with a steel straightedge across between the rails and a type-high gauge, and tape the rails if necessary with a hard durable tape like a steel adhesive measuring tape some hardware stores sell. Once you have the rails type high you can worry about the rollers. Your trucks should be truly concentric, as well as the rollers, and the trucks should be no more than 1/16” larger in diameter than the roller rubber. Everything has to be nearly perfect for photopolymer.

Bob

You are approaching this problem with too many variables as Dick and Bob pointed to. Instead of measuring against the rollers, use a straight edge across the top, middle, and bottom of the rails and measure the distance to the bed. Ideally you will be type high at all locations. Knowing if these measurements are more, or less than type high, or inconsistent, will determine the advise you will get next.

There have been discussions on similar issues in the past. Here is one post of related comments, but I’m sure a detailed search will provide more.

http://www.briarpress.org/21589

A quick trawl of The Web, seems to imply that the machine in question, is NOT cast as one with the Bed & The rails, >>Screwdrider, head Machine screws<< are in evidence, could it be as simple as adjusting the bed to suit the rails, is there possibly concealed behind the bed, register adjusters, occasionally square headed bolts, with small convex, contour, at tip of the thread.? Are the Horseshoe slots in the Roller Hooks, X 4 worn less than parallel, and binding on the New Roller Stocks.

How are you locking your form up, i.e on a reasonably flat surface, (preferably a proper Stone), ! do you plane it down gently, of course before your final lock up, by default is it locked up too tight to allow 99.9% contact, type to bed, is the chase known to be accurate, on the flat, is it warped and tipping the type up under lock up, will it sit in the machine in One oreintation only.

Just possibilities, apologies for rubbish.

First, thank you for all of your suggestions! I really appreciate your help.

The press has been refurbished and new rollers and trucks were added. I have noticed that sometimes that the rollers will slide just slightly at certain points rather than rotate. Not always, though. Is there a way to correct this?

I measured the top, middle and bottom distance to the bed using a straight edge and all three spaces are 30/32” (0.9375).

I am printing with polymer plates and am locking up the form on a flat surface. The chase seems to be accurate.

Thoughts?

Nicki

Check to be sure there is a little space between the roller trucks and the roller hooks. If the trucks are tight against the hooks they can bind a little and that could cause the sliding of the rollers that you’re seeing.

If the rails are truly .9375 above the bed that could be contributing to the inking problem, as that is almost .02 inch too high, so raising the rollers that much. The suggestion of shimming out the chase and plate may be what you need — about 1/50 of an inch build-up. You could try adding sheets of cover or index stock to the back of the chase one at a time until you get satisfactory inking.

Bob

Congratulations on your straight-edge rail measurements being consistent. Most buyers of old presses aren’t so lucky. The consistency you measured with the straight-edge makes any future adjustments much easier.

Since your rails are slightly higher than type-high, that would suggest to me that any new rollers you order in the future be perhaps 1/16 -1/8” larger in diameter than the existing trucks. Not the optimum choice, but in my experience, not usually enough to cause slurring with soft rubber or composition rollers (on type).

I agree with Bob’s suggestion of gradually lifting your form as your next steps.

Since the polymer pond is a place I don’t swim, I will leave you to the plethora of debates by those who do.

http://www.briarpress.org/8653

There are plenty more where that came from. Posts regarding the subject on BP could keep you reading for years.

Are the return springs on the Roller arms, of equal compression, side to side, as the problem is always one sided, is the/are the, spring(s) on the right hand side being overpowered by the spring(s)on the left hand side.?

Easy test, with Fisherman`s style spring balance, equal poundage, at same length of pull.? or not.

Is it possible to do an Engineers type Clearance test, i.e with a second pair of hands, stopping the rollers as they traverse the image with slivers of decent stock or acetate sheet 1/2” wide x 12” long, to ascertain where the contact disappears, is it the same place every pass, pointing to variable *X* factor.?

Rollers skidding rather than rotating, H/berg,s solution from a long long time ago, well documented, tiny amount of Rosin powder on the Rails and Trucks.