Issue with Challenge Paper Cutter

Hey Guys,

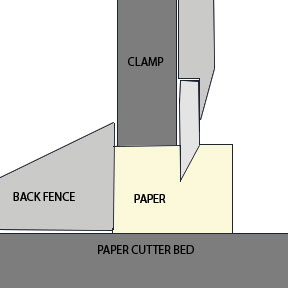

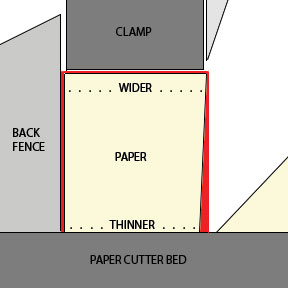

I ran into an issue with a old Challenge Advance (series 2) paper cutter. The cuts that I’m making are slightly uneven, between the top and the bottom sheet of a 2” stack, there’s about 2-3 point difference. The top sheet ends up being wider than the bottom and there’s an even gradient all the way down (so it’s not just a few sheets are odd-sized)

Blade Sharpness: It’s sharp (was sharpened this past monday)

Pressure: I’ve tried light, medium, and heavy pressure (screwing the clamp down until I couldn’t tighten it anymore)

Back Fence: Is square to the cutter table.

Paper Stock: for the job I ran into the issue with, i was cutting heavy stock cotton paper (530gsm) - but I have a smaller triumph cutter that can cut the same stock, same thickness, and not run into the same problem.

If anyone has run into this before and could offer some help troubleshooting, it’d be appreciated. This has been a real head scratcher.

Thanks in advance (and happy new year!)

pcutter01.jpg

pcutter02.jpg

Two points to check.

1/ The blade guides on either side.

If there is too much slack, the blade will drift.

2/ The blade mounting bolts can, if too long,

cause the clamp to deflect the blade as it is

swings past it.

Concur with above, I’d snug up the gibs.

Parts 35, 36 in the linked pdf diagram. There are two adjusters on each side. Your cutter may be similar.

https://www.dropbox.com/s/onqny2n4eg0fnax/Challenge-CutterF.143-A-p13%20...

I’d oil the cutter weekly, including the sliding surfaces.

Lube, yes!

Lube everything but use oil only at the oil ports

the clamp screw, & the fence screw.

For the blade guides (is “gibs” the correct term?)

you can use graphite I’ve heard, but better yet, use wax.

A block of canning paraffin or a hard candle

rubbed on that portion of the knife bar &

all surfaces engaged with it

will give you smooth performance

without getting oil on your work.

I’ve not had as much luck with the spray-on wax

used for motorcycle and bicycle chains.

Someday, however,

I’d like to try spray-on wax for the fence screw.

I’ve had some trouble keeping it free of paper fibers

which will jam the mechanism.

Wax is less sticky than oil & less likely (I think)

to collect the fine particles that drift down

through that slot in the table.

AnonyMouse….

Is that exploded chart

for the Challenge cutter

available on line?

I’d prefer to use correct

rather than “folk” terms.

Thanks,

Calvert

No problemo…

http://www.challengemachinery.com/manuals/F.143-A.pdf

Info for many cutters at the Challenge site.

One last thing you might want to check, that your knife sharpener is grinding ther knife to the correct specs. degrees to the knife face, could be anywhere from 21 thru 25 degrees. You might have to experiment with that.

Ragpicker Press, don’t know if you were referring to the word “gib” as a folk term or not. But gibs have been around for centuries. Challenge even made gib oil in a can that you use to be able to get. I know, because I have a can somewhere. Just thought I would pass that along.

Winfred Reed

Black Diamond Press (Kentucky)

Reread in sequence, WR.

I was calling them “guides”

but was glad to know the correct term

rather than what I’d either heard or guessed.

I was thinking the chart might be useful.

I tend to prefer conventional terms

but I don’t make a fetish out of it.

Sometimes folk & local terms do

seem a mite richer but teaching

college classes obligates me to

use the correct term & when it’s

possible & interesting, offer the

word’s origins.

We used to call certain kinds of shaft keys, “gibs”

and I believe I’ve heard the label used for other parts.

But thanks, I never get tired of getting schooled.