Die cutting on press

Hey friends! I have a question for you.

Pertinent info: C&P 8x12

I’ve done a few die cutting projects on press with lots of success, but with relatively small dies.

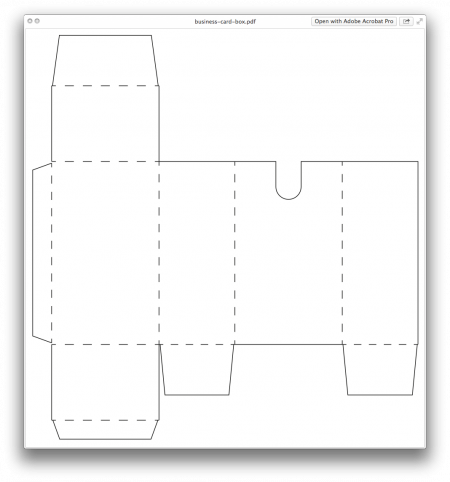

I want to have a die made so I can make custom business card boxes (for when I send clients their final deliverables).

However, after all is said and done, the die would max out the height of my chase. I’m wondering if this will end up being a problem in the production phase. I have no idea if it is bad practice to max out the platen/chase area with a die. Will I run into issues of getting a clean cut/score all the way around?

Any and all advice is welcomed. My backup option is to run the die, by hand, on my line-o-scribe proof press, but I don’t know if that is a bad idea, either.

Thanks!

Screen Shot 2015-03-19 at 11.27.33 AM.png

Well, there is a dirty pool solution to this: Is the die larger than the platen? If not, and you have a full coverage die jacket, have the die board made the full size of the chase and put the entire die in as you would a chase. A good die house can chamfer the edges to allow for the chase clamp and the bottom brackets.

However, it appears your die is too tall for even all that and that you may need a bigger press. You do not need the top and bottom horizontal cuts (on left side), as those can be done on the paper cutter after die-cutting.

That’s a great idea mike. I’ll go ahead with that in mind, I think.

Can you foresee any issues with the actual cutting of the piece?

i have cut with a “full house” die, no chase. it works fine. i don’t see as where pulling those horizontal rules will really save you much as the angled cuts need to go out that far anyway.

i think the issue here is going to be total pressure, the cut rule with all the crease rule adding up to possibly more than your press can take. if you really want to do these yourself, try it in all one pass,,, but be ready for 2 passes maybe? one to cut and one to crease?

otherwise, contact me, i will give you a “price you can’t refuse” on the cutting,creasing, with your die and stock.

Not knowing the size of your press, the die looks like it could be too much for it to cut out cleanly and you really do not want stress the press too much, these old machines are cast iron and it don’t take much to break. A cylinder or if you have an oversized press will work better. I’am also a die maker/die cutter in Northwestern PA been doing it for over 35 years love doing work for printers.