Windmill Inking issue

Hello-

Setting up a print run on the Windmill today and running into an inking problem I can’t figure out.

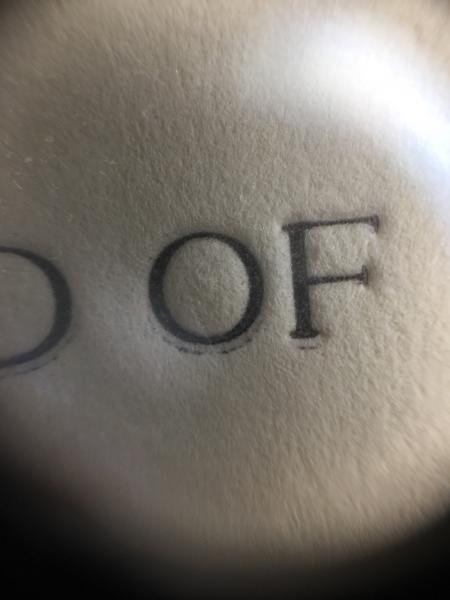

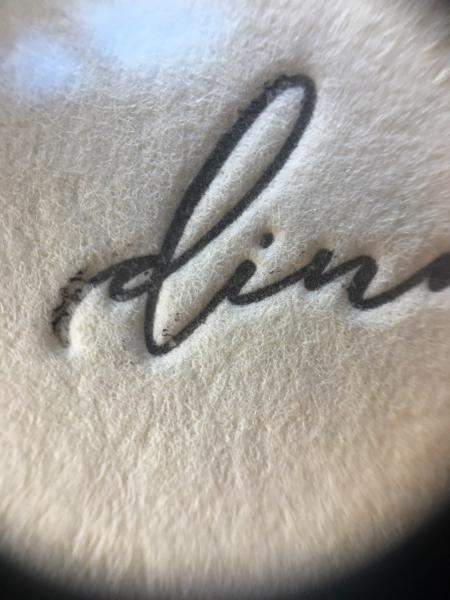

In a few spots on the plate, ink is not transferring on type face but just above the face. Consistent happening in same areas with other areas on an off. Rest of the print looks good to my eye.

See pics below- particularly the ‘d’.

I increased the impression to clearly show where the ink is and is not.

I’ve stopped printing to post this as I am starting to go in circles w/ my troubleshooting.

Look forward to some input. Will be heading back into shop soon to resume efforts. I’m even up for a phone call if someone is really feeling adventurous!

Thanks,

Blair

IMG_3776.jpg

IMG_3779.jpg

IMG_3774.jpg

My first check would be to look at the type to see if the shoulders and counters are being inked, in which case the rollers need resetting. If you are printing from polymer and the non printing areas are being inked then it’s either rollers too low or plate too high. It might be worth trying to print some standard stock , i.e. laser printer paper and try kiss impression to see if that works. Good luck.

I agree with Frank, I’d check your roller height.

I would also check if your paper is sitting flat against your platen. If it’s bowing out, it can effect printing — the bowed out part touches the plate first and the ink sort of smears, which is what some of your photos might look like.

Thanks for the responses.

I rotated the polymer plate 180 deg. and the issues stayed with the rollers area, not the plate. Then I rotated the rollers left to right and the issue seems to have resolved. So look like it might be a roller issue. Will see if it holds once I dial back in the roller height.

Has anyone seen this issue (the letter ‘d’ and ‘S’ pic above) from bad/worn roller?

I agree with Annie and Frank; there’s one more thing I always check—make sure your roller tracks are absolutely clean and dry. Ditto the roller trucks. I clean mine daily. Roller slippage can cause problems as you show in the 2nd and 3rd image. The first image looks more like the paper isn’t flat.

Make sure you base is level. Check to make sure a there is nothing under ( on the back ) of your base. If you don’t have a stone I like to use my cutter bed. Release the lockup and flatten chase and components. Then re apply pressure and test print.

I use my cutter bed also. In times past we would get stones from the local monument works that made headstones.

Very reasonable. The ones we had were maybe an inch or so thick. If you need a stone, start there. You may get a deal on one with a typo. Just flip it over and use the backside. Ask for a scrap first, don’t pay full price for a custom piece.

Update: issue solved

Recap: Issue being the ink “skipping” as shown on the ‘d’ and ‘s’ in pics above. Ink intermittently not sticking to face of polymer plate and ‘smearing’ past image.

After rotating rollers and plate, thought I had isolated issue, but after I got back to printing volume, the issue re-emerged.

Resolution- it was the paper. I was using Arturo, and I realize the issue was only happening on one side paper stock. I had not been tracking paper side/grain and the pile had become mixed in the cutting process.

Turns out the ‘rougher’ side of the two, was creating this intermittent ‘spot’ ink rejection. After I switched to only inking the more uniform side, issue 100% resolved.

I had not considered this paper to be “side/grain’ dependent for letterpress and rubber based inks.

Thanks all for all the help/comments.