Roller Height Help - Cropper, Charlton & Co Peerless No.1

Hi all,

I have recently been trying to set the roller height on my Cropper, Charlton & Co Peerless No.1 to try and iron out some ghosting and slurring issues and wondered if anyone can help.

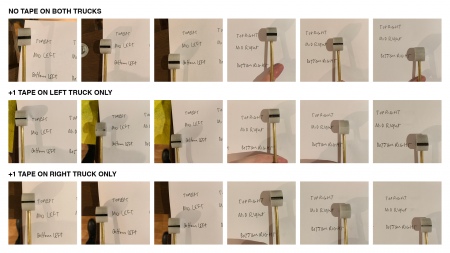

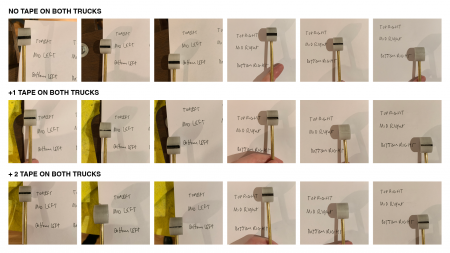

My initial tests found that the lollipop strips were pretty thick all over apart from the bottom right corner which took no ink at all

After having a look on here I decided to try taping the trucks first instead of the rails (I’ve seen a few battles over this!) to see how that would go.

I have spent the night documenting each test to try and see if I could make anything out of the results but I’m still stumped, it would be great if anyone on here can make anything out of these!

I have uploaded a more detailed images to view here:

https://www.flickr.com/photos/141670721@N06/51712482059/in/dateposted-pu...

https://www.flickr.com/photos/141670721@N06/51712085898/in/dateposted-pu...

I tested with 1 piece of electrical tape on each side, on both, then 2 pieces on both.

I still feel like the bare trucks give the closest results apart from the bottom right corner and thought I could possibly pad out the back of the chase bed in that corner to bring it forward? Or would that be a bad idea?

Any help would be much appreciated.

Thanks,

Kris

Roller Ink Tests.png

Roller Ink Tests2.png

Hi Teikaut,

Thanks for the speedy response, I have updated the image links to Flickr links if you want a better look.

I have cleaned and buffed the rails as much as possible and they are very clean, it seems like the chase bed may be further back at the bottom corner that isn’t inking.

I had my rollers made based on the truck diameter, when I bought the press it was only the cores left so I got them recovered. The trucks are metal so I have wondered whether these may have worn down over the years? Would new trucks maybe help the issues?

I have a few more images of my press and rollers that may be of use here:

https://www.flickr.com/photos/141670721@N06/albums/72157669855866118/wit...

Thanks for taking a look.

If the problem is with your rollers or trucks, flipping them around should also move the problem. Have you tried that?

I would also check the tension on the springs through the motion. I had a friend whose press didn’t put enough pressure on the roller at the end of the rail, on one side. This lead to the roller slipping and dragging across the plate instead of properly depositing ink. This would also have resulted in a thinner line on the gauge.

New springs are probably cheaper than new rollers :)

-Kim

Thanks Gerald, it’s been a labour of love over the last few years of repairs! I’m going to have a go at placing something behind the bottom corner of the bed to see if it makes any difference.

I had another look over the trucks and when placing them together I have noticed a bit of a slope in the centre of most of them, uploaded a few more images for reference here:

https://www.flickr.com/photos/141670721@N06/51715310198/in/album-7215766...

Interestingly, when I tested rotating a truck in one place while testing the roller it was giving different thicknesses on the lollipop, making me think there is inconsistencies in the height of the trucks.

I think new roller trucks may help out in general so I have started a conversation with someone who may be able to make some up for me.

Thanks Kim, interestingly some of the springs on the press had some wooden blocks behind them originally which I was advised to remove on here, I have thought about buying a new set of springs and wondered if there is a way to calculate the size if some springs may be worn? Any ideas?

The rollers were covered professionally so are brand new and shouldn’t be worn out so I’m hoping it’s a mix of the bed being too low in a corner and the trucks being worn out.

Thank you both for all of your help!

I specifically meant flipping the roller so the right-hand truck is on the left-hand rail and vice-versa.

Using calipers you should be able to verify any non-roundness of the trucks in a couple of seconds.

If you bring your old springs to a good hardware store, they should be able to suggest replacements, they don’t have to match the originals perfectly, they just have to apply equal pressure. If there were blocks, they might have been to compensate for worn/stretched springs, removing them would mean low tension.

You probably don’t *want* it to be the bed itself, because that is an incredibly difficult repair, or a lifetime of compensating with makeready. My first press had a low spot and I spent almost five years completely avoiding the lower right hand side of the chase when designing :)