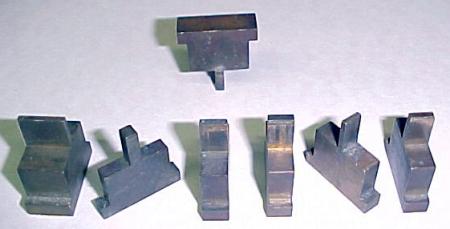

A Hot-Metal (Ludlow?) Whatzit

I recently bought another batch of Ludlow stuff and in the bottom of a pail, that had mostly Ludlow parts, were these items. I have no idea what they are or how they were intended to be used. I don’t even know if they go together. What I’ll call molds have an internal width of 6,8,10 12 and 14 points respectively. All of them have the number 5810772 on both sides so the only difference that sets them apart is the width of the spacers on each end. They are 5 1/4” long, 15/16” wide and 1/2” high. The slot is 3 7/16” long and is smooth on both sides.

The second part of the dilemma are the Ludlow “mats”. Obviously they are not standard mats but they are made out of standard 7/8” Ludlow spacers. The tongues are 15/32” long and are varying widths and thicknesses; 6, 8, 10, 12 but no 14 point. I have a bunch of these.

Does anyone know what this stuff is all about? I’m quite familiar with Ludlow as I have 500+ fonts of mats, 4 machines, parts to another 4 and have rebuilt one from the camshaft up.

Thanks, John

Whatzit 1.jpg

Whatzit 2.jpg

Whatzit 3.jpg

Whatzit 4.jpg

Whatzit 5.jpg

Correction: The molds do vary in width slightly depending upon the point size. Also the number is as shown in the photo, 5810773.

Does it appear these could be used for casting from Linotype mats? If so, I would like to have some precise measurements so I could reproduce a set.

jhenry,

My first thought was that these were to be used with another type of caster but the varying width of the “molds” makes no sense to me in using them on a Linotype. But then, I’m not that familiar with Linotype (had to draw the hot-metal collecting line somewhere).

If the molds all have the same outside dimensions, I would suspect that they are meant for casting Linotype mats in a Ludlow Machine. Perhaps they fit into the mouthpiece somehow?

The Ludlow “mats” are likely for filling the mold for casting short lines—since any open space would likely yield a hefty squirt.

John:

I didn’t mean for casting ON a Lintype, but for casting on the Ludlow FROM linotype mats. But that would not allow for shifting the mats with two-letter format.

Hopefully someone will come up with a reason for being.

mike, unfortunately the ‘molds’ vary in width depending on point size.

I thought about the Ludlow ‘spacers’ being used as you mentioned but the real Ludlow mold is 3/4” thick yielding a blank slug 3/4” tall. The tounges on these ‘spacers’ are less than 1/2’ long. Plus, the real Ludlow mold and stick alignment would have to right on within a thousandth of an inch or there would be a bad collision.

ludlow molds have 4 screws to hold them in place and they are water cooled, i don’t see how these molds would be put on a ludlow. the mats i have never seen before, if you cast them it would leave a deep groove in the slug, i think. there must be someone out there that knows what these are.

dickg, I’m hoping so. But here’s another wrinkle to the puzzle. In this mix of Ludlow stuff I also got a 4 point, an 8 point, a 10 point and a 14 point Ludlow mold. I know about the 4 point mold because I paid the big bucks and got one and the matching ejector knife via eBay a few years ago. The 14 point mold is obviously some machinist’s creation from another 4 point mold. However!!, the 8 point and 10 point molds are factory made and marked as such on the top by the hose connections in the traditional manner. Has anyone ever seen an 8 pt. or 10 pt. Ludlow mold?

Yes, I have molds of varying widths including 10pt. which I regularly run on my machine. if setting text sizes using the proper mold can save using a lot of ledding between lines when setting multiple paragraphs of text. I don’t think I have an 8pt. mold, however.

What I was meaning was, is the exterior dimensions of the “mold” pieces the same—this appears to be the distance between the “ears” of a Linotype mat—or alternately, the parts might be to allow the casting from border slides or some other setup.

Mike,

My original description was wrong. The “molds” do vary in width depending upon the point size. I just dug out a Linotype mat to try your theory and none of the molds fit between the ears. One comes close but it’s too snug to be what I’d call a fit plus the letter doesn’t line up with the slot.

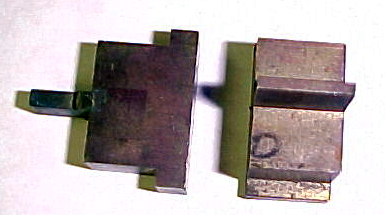

I’m beginning to think that these aren’t molds at all. The spacers on each end are held in place by Allen head screws and in some cases the spacers are not perfectly flush with the outside. A mold wouldn’t be made like that I don’t think. Besides that, the insides are smooth and the ends of the slot formed by the spacers are vertical. Not at all like you’d expect a mold to be made.

Thanks for your ideas. I feel badly having to shoot them down.

Did you have any luck in finding out what these items are?

I’m trying to find a way to cast from Linotype border slides using my Ludlow and would appreciate any thoughts folk may have on this topic.

Obviously, a Linotype border slide would not produce a usable slug from a Ludlow unless the casting surface of the slide could be positioned at the same alignment as the casting surface of Ludlow mats. That leaves a lot of extra body that needs to be formed between the mold and the slide, so a stick/casting block combination that becomes an extension of the mold is needed, and preferably this would have adjustment for different sizes of slide. Accomodating a full 30 pica slide would be a real challenge.

I have a border slide that has a projection like the whatzits in 4 and 5 above. Strange.