Victorian Labels - How were they Printed?

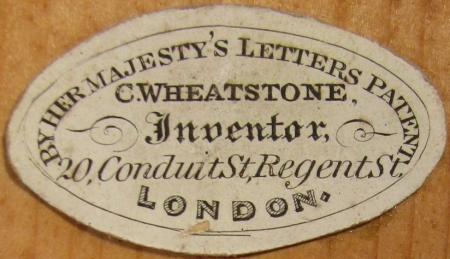

This concertina maker’s label design dates back to 1844, I believe. The oval is roughly an inch wide. There must have been thousands of copies of it printed over a period of several decades. I would like to learn what techniques were used to design and print it: in particular, how did they make the printing plate?

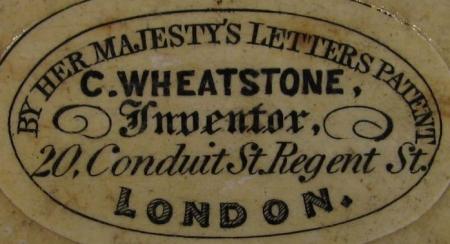

Interestingly, there are at least two slightly different versions of the same logo - I wonder if this indicates that the original plate wore out or was damaged/lost at some point and had to be re-made from scratch?

I’ve also attached a label from a different maker operating around the same time period, presumably printed using the same techniques.

wheatstone3.jpg

wheatstone9.jpg

lachenal2.jpg

Those look like stone lithographs to me.

Without a glass, the actual print method is difficult to ascertain - especially on a computer screen. However, the labels appear hand set, especially the rule working (the dips are different sizes in each label; the ovals are crudely formed, and distorted in the lock-up.). The uneven baselines indicate judicial filing in order to reduce set width, and creative locking of the lines.. I’m also thinking that a litho set-up would have produced a more even and balanced overall label. That they are in such good condition for their age is remarkable. :o)

I would say stone litho or maybe intaglio, like copperplate engraving. I don’t think it’s handset because if you compare most any two of the same characters in the same label, there are small differences in them.

I see, thanks. I had also come to suspect hand lettering because of the minor variations between duplicate letters. Lachenal’s is pretty consistent, except the letters of the phrase “PATENT CONCERTINA” appear to subtly vary in size along its length. It’s hard to imagine how the engravers were able to consistently produce such fine detail by hand.

Would a stone litho have been durable enough to print thousands of impressions? I was wondering if they might have engraved a boxwood or copper master in relief and then used a technique like stereotyping or (as somebody suggested in a private message) galvano/electrotyping to make multiple metal copies of it for use in a press.

Incidentally, the reason I am interested in this topic is because I am designing a logo for my new traditional concertina-making business, and I want to copy the Victorian style as closely as is practical and print the labels myself on an Adana HS1 press.

The top label was most certainly engraved by hand, the other two don’t represent the same quality but may have been engraved. Without examining the label I couldn’t tell how it was produced but it may have been engraved on a plate press or the image may have been reproduced from the original engraving to be printed on letterpress or some other equipment.

People used to sit down, draw out their design on paper, transfer it in reverse to steel plate and cut the image by hand with a burin. The changing pressure applied by hand and the turning back and forth of the “V” shaped burin gives the line it’s unique character. That’s how it was done in that time period. It’s amazing to us now since we design on a computer but people used to get the skill to do that by repetition. Simply drawing their letters and designing with them every day and building up a repetoire of styles that they became familiar with cutting. When you see a design like this that has been engraved by hand you can see the small differences in letter shape and spacing and thickness of line.

If you have the skill to hand draw your label, but not engrave it, then it might be your best bet to make your design style replica oversized and then reduce to size and make a letterpress plate for printing. If your drawing skill level is somewhat less developed you can use any hybrid method to get a design going using a computer graphics program and then use a light table to trace the design to give it a hand made character and then make a plate from a scan of that. It won’t have the same character as hand cut engraving but it will look hand made.

Also there are still folks around who could engrave your design.

Best of luck

Thanks Bruce. What features of the top label enable you to tell that it is definitely an engraving? I notice some of the italic letters are partially hollow.

I’m not certain, but I think the top label is from a very early instrument, when production volumes were low and construction methods more labour intensive.

Hi Alex the top label especially shows the very fine line of the very light pressure of the tip of the burin flair out into the thicker meat of the letter as pressure is increased and the tip is rolled side ways while maintaining an imperfect but flowing arc.

Since the plate would have been inked and wiped by hand it would not be unusal to have small inconsistancies where the ink was wiped out of the lines by pressman.

As I said there are things you could do to try to reproduce this image character in other modern ways but looking at this picture it does have that hand engraved character.

If you look at the back of the label you might see diffinitive marks to show if the label itself was puller from an engraving plate press and that would be slight indentation, the opposite of the bump letterpress type would make, where the press blanket would have pushed the paper into the incised lines of the engraved plate. Lack of the indentation would not be evidence one way or the other but it’s presence would be pretty staightforward.

What I personally do when creating something like this, is design it first on the computer (whether using modern fonts or scanned letters from older specimen books) print out an oversized copy, then trace it by hand (to add that level of subtle imperfection). The result it scanned back to a computer, outlined, reduced in size and is ready for the platemaker.

Granted, in the example below I am trying to imitate a woodcut rather then copperplate engraving, but the principle holds.

Tracing the computer printout

Resulting letterpress print

Very nice work Oprion’s Kelsey produced!

Thanks Bruce, that’s very useful to know. Unfortunately I don’t have any original labels to examine - these photos are from the Concertina Museum Collection website and show unusually well-preserved examples. I own two antique Lachenal instruments but they have both lost their labels at some point.

Good idea Oprion, that’s probably what I will do.

Oprion, That’s a nice print. Photography is great too.

It was not Oprion’s Kelsey that produced the fine work….. it was Oprion.

I’ve often heard it said here at Briar Press that “a Kelsey cannot produce fine work”…. and by itself I’d have to agree. Then again, by itself neither can a Vandercook or an H-berg. BUT when the Kelsey or Vandercook is used by someone who is very good….. prints like that result.

Back to the topic: I could agree that the top label might be an engraving, but not the bottom one. It has the characteristic lack of sharpness that a well-used litho stone produces. The middle one could be either engraved or litho’d.

One way to know for sure would be to feel it for texture / impression OR maybe photograph it with a very skewed light source. If it’s got a 3D texture, then it’s not litho.

As much as I love my little Kelsey, I gotta says, getting a decent print from it is always a challenge. At the last Iowa Printer’s Fair I finally had an opportunity to print on a C&P jobber, and boy what a difference! I printed a badly locked, unplained form, smudged all over with greasy fingers, on less then virginal tympan, without a single bit of makeready — and it came out perfectly! A comparable result (the form size was well within a 5x8 scope) on my dear old Kelsey would’ve taken hours of meticulous work and lots of trial and error.

But then, quick & easy ain’t the letterpress way!

Alex Holden, there is an auction on ebay with plates similar to your label questions.

Here is the item number (141565860122)

best james

without seeing them personally-pretty standard practice for an individual engraved image, or etching, or letterpress at times even to have many copies made, patched up and transferred to a litho stone for printing on mass.

I think it could potentially be stone engraving or some sort of transfer method. Transfer litho seems quite likely, but there were engraving machines which could follow patterns in way similar to a pantograph, one end being a guide point the other being a stylus that scratched into a litho stone. One could freehand with these or use them to engrave from patterns. Reverse the patterns and you have a backwards drawing for the stone.

The basic procedure of stone engraving:

Most people know litho stones or plates are treated with gum arabic to produce a hydrophilic layer which rejects oil/ink. But this is not permanent, and can be scratched through to remove, especially if very lightly treated.

Ergo…

Litho plate or stone gets buffed with a thin layer of Gum Arabic, which has an inert pigment tint added to it so you can see what you are doing. Smoothed down very fine and even with cheesecloth and allowed to dry.

The artist uses some method to scratch through the gum layer, into the surface of the plate or stone very very delicately. Needles or scrapers or even sandpaper are used, and the stone appears ‘white’ where successfully eroded.

The trick is to be soft handed enough to dig just into the top layer of stone, not too deep as taking care not to make a gutter which requires a lot of pressure is preferable.

It’s not an intaglio method but a precision deletion method.

There were machines that could be used to hand-follow patterns and use a stylus capable of making very fine lines.

Here is an example of a stone engraving:

http://blogs.law.harvard.edu/houghton/files/2011/08/ElizaCover.jpg

Looks sort of similar, no?

The advantage being it printed much more consistently and quickly, with the ease of the lithographic process and assistance of mechanized equipment.

The other potential lithographic method would have been a transfer paper. Ink a composed type graphic up with transfer ink, apply this to transfer paper- paper that had a very carefully applied ‘release’ layer made of gelatin, kind of like temp tattoo paper in a way.

While the transfer ink is still wet, the transfer paper gets dampened on the backside very lightly (disengaging release layer), it is then applied ink-down over the stone or plate, run through a transfer press with a bit of pressure, and voila; image is moved from transer paper to the stone.

Normal chemical processing follows.

Jean Dubuffet applied this method with great success to a variety of lithographs, for example.