Heidelberg Windmill Registration Problems

Hi everyone

I am about ready to pull my hair out over this one. I have had perfect registration in the past on my windmill and now things are going wonky.

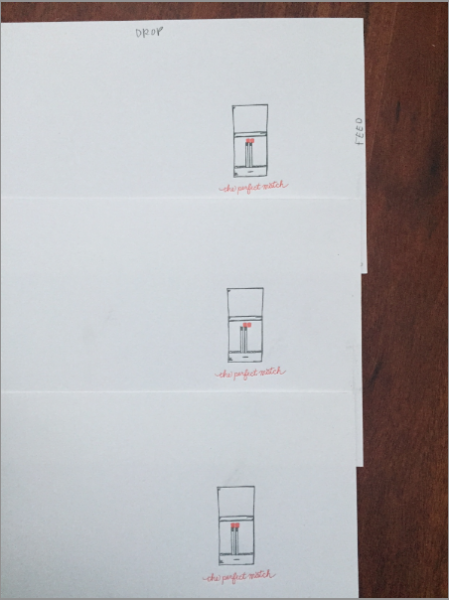

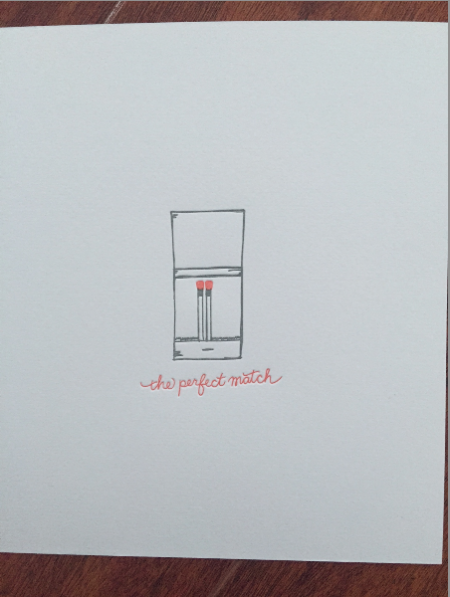

Vertical registration seems spot on, but the horizontal registration is off by several points. Sometimes 2 pts, sometimes as much as 6 pts. (pics are below—the bottom pic shows the correct registration) At first I thought it was one of the grippers as it was happening consistently with one gripper, but on this last run I printed, it was happening with both grippers.

Things I have tried:

—adjusting side guide: all the way out, all the way in, somewhere in between

—making sure tympan is nice and tight

Any other suggestions? I still think it might be something with the grippers. Anything I can do to test the grippers or adjust them? I don’t have any rubber on them right now, but was reading that might help.

Thank you!!

kim

Screen Shot 2015-01-05 at 4.54.40 PM.png

Screen Shot 2015-01-05 at 4.54.32 PM.png

Sheet may be bouncing off side guide try the “Flying Dutchman”

I often apply the technique whether I need it or not.

Try slowing the press down and see if it’s still bouncing. For heavy sheets, I have to put the side guide as far out as possible.

the far edge of the sheet (opposite of feed/guide edge) isn’t catching on something. loading up then “springing” loose? maybe a forgotten piece of scotch tape? a small tear in the tympan down by”drop” edge? try sliding sheet by hand, (try multiple positions of press closure) to see if it “catches” on something? sheet might be being “pinched” somewhere?

Thanks so much for the replies!

Mike—I have never tried this technique. I just looked it up and it might be worth a shot.

jonsel—I am currently operating the press on the slowest speed, so I think I can rule that out. I may try messing around with the side guide a bit more…wondering if it’s a combo of the side guide and grippers as it is now happening with both grippers.

ericm—i took a close look at the tympan and there doesn’t seem to be anything in the way. I am using a fresh sheet and it is nice and tight.

Things I may try:

1. adding electrical tape to the gripper edge to see if it’s something with the tightness of the grip.

2. cleaning off the brass guides to make sure there is nothing sticky on them.

3. messing around more with the side guide. I’ve been running the press with it in between, but will experiment with it all the way out.

If the electrical tape doesn’t work, does anyone know where I might find the sheet rubber to add to the grippers (.012” thick according to manual)?

Any other ideas to try?

Kimburks-

I have used electrical tape on my grippers and it works fine, only thing I might suggest is to check your grippers to verify there is on residual glue from previous tape that may cause the sheet to stick to the gripper rather than drop onto the guides and then push up and over to the side guide. Clean them well. I have also used Peters trick of 2 sided tape on the guides to make sure the sheet is moving and not sliding on the guides.

Good luck-

Jim

Maybe you are having a problem with static building up and causing the paper to misregister. You could hook up tinsel and/or use anti-static spray.

I recall Peter or Mick using strips of doublestick tape in the channel of the lower gauges to keep paper from sliding back away from the right sidelay. The lower lays should be far enough apart to keep the stock from rocking when dropped.

Another thing to check is the large silver shouldered bolt that has just two flats, that the sidelay lever pivots on. If that bolt loosens, the sidelay can move sideways and cause erratic registration.

Another item to ensure is the position of the leftmost feedtable standard, the one that is stopped by the part that says:

<—— Brass Gauges

Nickle Gauges ——->

The above standard should be far left, to help the sheets from bouncing from too high of a drop when the grippers open. The standard can get loose, or debris can get under the standard when shifting position, causing the standard to rock or wiggle.

I’d start a print and stop the press right at pickup, then advance the press slowly by hand and watch the action closely through the process, to see if there is any interference by grippers, packing or parts out of alignment.

Chime back and let us know how you get along…

AM

I take it that you are using brass lays, if so do you have wire pins in the holes in the lays. If you are using only the grippers you will never get good register. REGISTRATION is when you sign up for some sort of service or enrol in something.

Are there any letterpress print shops in the Wide Bay area of Queensland, Australia ?

I was curious about rroddi’s comment on registration vs. register. My two immediate sources are Porte’s “Dictionary of Printing Terms” 1923, and Mills “Platen Press Operation” 1959. Porte has 4 listings containing register: Register, Register Hook, Register Mark, and Register Sheet. And Mills has several references to Register and one reference to Registering device. Neither uses registration and appear to be very rigid on using only the word register. Perhaps if I widen my search I will find the same results in other sources.

Make sure the first color didn’t jump also. If the first color printing didn’t jump, that paper has static building up.

I have this problem on my 8x12 at time, I rub baby powder on the packing and the sheets no longer hang up.