new press repair questions. please help!!

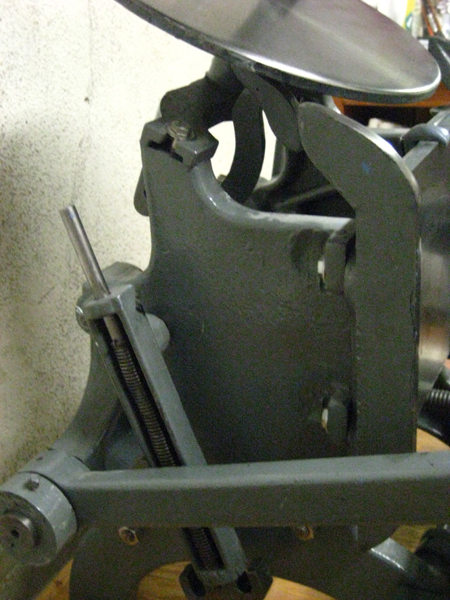

i posted this under troubleshooting, with not much response. i have been about to figure the problem out, now i just need help fixing it! i just got a press, and the left roller hook arm is not securely attached. i was able to tighten it almost all the way with an allen wrench, but not tight enough to stay, especially through any amount of printing action.

another question i have is that one of my rollers is a little bit longer than the other. is that normal? does it matter which one goes on the top and which on the bottom?

neither of these things seemed like problems for the last owner of the press, so i am feeling at a loss and just plain ready to get printing! i have included pictures, hopefully they are helpful.

also, the last picture is of a part that was delivered with the press, but which the previous owner wasn’t sure. can anyone tell me where this goes?

broken arm.jpg

uneven rollers.jpg

mystery spring.jpg

If the aluminum Craftsman press is like a C&P Pilot then there should be a taper pin that runs through the collar of the roller arm and secures the arm to the rear shaft. Do you see something like this? Or a hole for such a pin?

Doesn’t matter which roller is on top/bottom and it’s fine that one is a little longer.

That mystery spring is a gripper spring. It spans between the gripper bar assembly and a hole on the delivery table bracket. As the press is closed the spring causes the grippers to move against the platen.

Hope this helps.

Brad.

If there is in fact a set screw on the left arm, there should also be one on the right. I suspect Brad is right — there should be a tapered pin, but maybe it was lost or sheared off and someone replaced it with a set screw. If that is the case you need a flat on the shaft that connects the two arms, for the set screw to tighten down on. It should be milled rather than filed, so as to be accurate, but you could get away with filing it if necessary, if you are careful to make it accurate. It must be in exactly the right position to align the left arm with the right one. Better leave that to a machine shop, if that’s what it needs. If it’s just a missing tapered pin a machine shop should be able to furnish the right size pin.

Regarding the different length rollers, it’s not a problem unless the longer one won’t fit comfortably between the roller hooks — looks in your photo like that could be the case. If you can move the trucks inward on that roller all should be well.

yikes, i think i am getting the gist of this, but i certainly don’t feel confident trying to fix this myself. i guess maybe my best bet is to get someone who knows more than i do to look at it.

thank you!