After my first job…A few questions

C&P Craftsman

Here are some questions with photos…

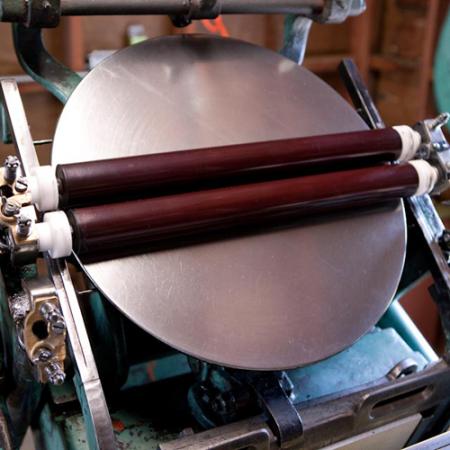

The first is the color change when using transparent white. After 35 to 50 prints. I think it is coming off my rollers and not because the color before was a burgundy color. Is the Coleman’s Camping Fuel making my rollers break down? If so what will help get rid of this? Do I need new rollers? I have no idea how old they are…they look they are in good shape.

Next…It seems that when running the any color as it gets to 50 prints I can see the color getting lighter and lighter. Why so soon? If I add more ink, in the beginning, they are way too dark. Also during the print runs I need to wait 3 to 5 cycles of the press before I can get the next print to be the correct color. (I am only using 2 of the 4 rollers)

And lastly…my motor died and I will be looking for a new 1 1/2hp 110. Any suggestions? Do you have a rheostat that you use to control the speed? I was thinking of Grainger’s?

Thank you for your help and suggestions! Have a good 4th-of-July weekend!

-sb

SB

roller 1

roller 2

motor

Bob2:

Are you certain the motor is dead? Maybe just needs brushes?

The color coming out of the rollers is a common problem. The pores of the rollers tend to hold color, and when going from a darker to a lighter color, an extra washup is often required. Chances are that the gasoline you are using is fine for the rollers but could dry out some materials over time.

Have you tried using a deglazing agent?

I use mineral spirits/california wash for my general wash-up, but if I was about to run a light or transparent color, I would want to deglaze the rollers and/or apply a color wash.

I’m really happy with Putz Pomade for these kind of intensive washes.

I used mineral spirits on my letterpress. it cleans off really well. You can find mineral spirits anywhere in hardware stores.

Here’s a trick I use when going from dark to light ink with rubber rollers.

1. Clean the rollers thoroughly. Use your choice of solvents - I follow-up with type wash. You can use deglazer or rubber rejuvenator. Putz Pomade is great, and there are other deep cleaning agents out there.

2. Ink-up the rollers with the light color ink. Run the ink in pretty good.

3. Wash the rollers again!

4. Ink-up the rollers and you’re ready to print.

n/a

I follow our offset printers suggestion by running the press with the Putz. It really helps to pull the ink out of the rollers. Of course it would be easier to run lighter colors or lighter jobs first if possible. Ron

Ron, that’s an excellent idea. I’m going to give it a try on my next color change.

-James Beard

Vrooooom Press

…even after running a black ink job…I cleaned the rollers and after 3x washes the rag is redish. It has been that way from the beginning.

-sb

n/a

Any recommendation on replacing the motor? After having it looked at the verdict was to replace it instead of trying to get it fixed.

I have a electrician looking for a replacement. 1 1/2 HP 110 DC (so I can adjust the speed) motor with a 1” shaft (so I can switch the drive wheel over)

Anyone ever have a new drive wheel made for their motor?

Any help would be grateful…!

-sb

Bob,

You said:

1 1/2 HP 110 DC (so I can adjust the speed)

I’m not sure exactly what you mean here. Your current motor is variable speed by the adjustment of the brushes inside the motor. That’s the beauty of an old Kimble motor.

Do you want DC or AC? I have AC motors paired with VFDs for a couple of my presses.

I wouldn’t worry too much about the shaft size. You can always buy a v-belt and matching pulley for whatever shaft size you end up with. I’d simply search online for a cheap new or used motor that fits your HP and RPM specs.

Hope this helps. Let me know if you have any questions.

Brad.