Trucks and tracks on the windmill

Are the trucks supposed to lift off the roller tracks at the top of the press once they go over the ink drum? The rollers hit the drum and lift the trucks off.

I’m having an issue where there is a blank strip on the form rollers after they come off the ink drum, and I think this might be part of my problem.

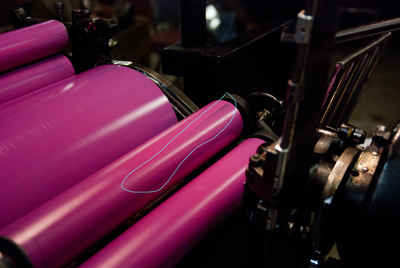

trucks-rails1.jpg

rollers with missing ink.jpg

There’s a roller lift that you can engage and disengage as needed. It’s used to raise the rollers when the press is not in use to avoid flat spots on the rollers. Any chance you have this engaged? There’s a small handle that allows you to raise and lower the uppermost portion of the rails.

Brad.

If the roller lift is on you would not get any ink on your rollers. Sounds like you already have a flat spot on your rollers, are they old or new rollers. Dick G.

The rollers are new, and I’ve been extremely careful to always lift them off when I’m done printing. Also, I’ve watched very carefully and the spot with no ink changes. It appears that when they move back down the roller tracks somehow the ink drum wipes off some of the ink. The “dry spot” is like an angled line. I think it has to do with the fact that the trucks lift off the tracks on the left side at the very top of the track. That’s why I was wondering what was the normal action at this point.

Your rollers should not lift on one side, your spring on that side might not be tight or the shaft is bent and the rollers could ride away from the track. When your done printing on a windmill you should remove the chase and run your rollers mid way up your bed, this will take pressure off your springs that hold your rollers, even on job presses this will work. Dick G.

the roller does not lift off, only the truck does. The roller stays on the ink drum the entire time. It’s as if the ink drum lifts the roller higher and so the trucks are no longer touching the rails. I’ve attached a picture to the original post to help explain.

My presses do the same thing, The rollers are in contact with the drum while the trucks lift up about 1/8” at the very top of the cycle. I think this is normal. I have no inking problems so maybe it’s something to do with the rollers. How long has this been happening. Did you wash up and try again?

Another thought is to flip the roller around and see if the blank strip changes. Also try changing the bearings.

I wouldn’t think that would affect your printing, it’s not a very large area. Do you have a rider/vibrating roller you can attach?

That would get rid of any ghosting you might be having.

Girl with Kluge, i thought you took up weaving, haven’t seen too many posts from you lately. Dick G.

Sarah,

Have you solved your windmill inking issues? If so, could you share your results? I’m fairly certain that most members of BP would be interested in the outcome.

dickg….no weaving as of yet….but it does loom in my future.

i’m curious too. Did you figure out what hoppened?

I added the rider roller, but I’m still having issues with inking. I think it’s just going to be a trial and error as I get used to my new press.

I am wondering if maybe the ink drum is turning at a different speed than the rollers and this is causing some of the ink to come off the rollers.

Are your rollers and trucks the same width?