Worn mats…

I finally got around to using our 12 point Garamond on our Intertype.

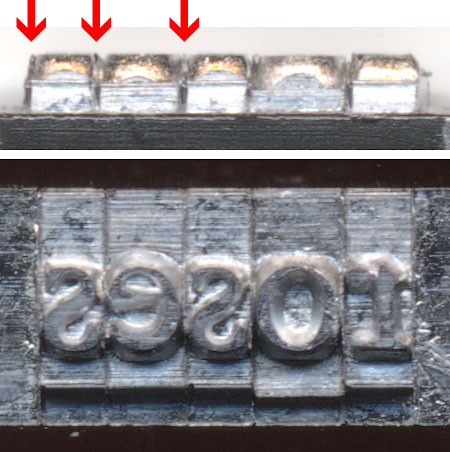

You can see in the side image at the top that there are thin lead peaks between the letters which print.

Is this from mats that are too worn (the mats themselves show wear in the are beside the moulds) or is it possibly that the mats are not being compressed enough when the mats are cast?

Any way to reasonably get rid of them so I can finish the job we are working on?

It happens between almost all lowercase letters.

I’m not sure if a scan of the mats helps, but I’ve added that.

Thanks for any advice.

intertype-problems-thins.jpg

intertype-problems-thins-mats.jpg

Those are “hairlines” and are an indication that the mold cavity walls have been crushed, through various means, allowing typemetal to seep between the mats and creating these ridges.

Early stages of hairlining can be combated by heavy impression with blotter paper, or scrubbing the form with a type cleaning brush before printing. As the condition advances, there is no way to get them out of a printed form.

It is an incurable and unfixable problem. Generally it is a sign that a font of mats should be retired. Pull a proof casting of the mats and pick out the ones that aren’t hairlining. Scrap the rest, as they should not be mixed with good mats or the issue will spread into them.

Largest source of hairlining mats is poor spaceband maintenance, other damage can come from the machine being dirty, or oil in the mat path.

Early stages of hairlining can be combated by heavy impression with blotter paper, or scrubbing the form with a type cleaning brush before printing. As the condition advances, there is no way to get them out of a printed form.

There is a brush with brass bristles in the center and regular hair bristles around the edges, sometimes it will help but if you go over the type more than once it will damage the letters. Mike is more than right, these mats need to be retired. Dick G. ps Mikes blotter idea is the best way to deal with these hairlines.

I would never use a brass brush on typemetal; it is meant for plates. The brush meant for removing hairlines was made of goosequills, and I suspect it worked by snapping off hairlines that are above the type face.

A friend recently told me about mat repairs services that were once available. Nothing like that today, but I wonder about how sidewalls could be repaired, since mat replacement is rarely possible. Soldering or electrodepositing onto the outside of the sidewalls? Or reforming them from the inside?

I would love to have one of those goose quill brushes. The place I worked at in Atlanta bought two, back in the late 1970’s. They really do work.

If you want to get another font of mats, Don Black Linecasting probably has them.

I had the opportunity to get a goosequill brush, but alas, didn’t realize the value then. It wouldn’t be hard to make if one had goose quills. There was just a wooden slab of a handle, like many other brushes, with holes drilled for insertion of the quills, which stuck out an inch or so. The quills were smashed lengthwise, so instead of tubes there were lots of flaps, all in parallel planes. Was it adapted from some other use, or just some printer’s brilliant idea?

parrellel, i’ve always used the brass brush, once over the type lightly seems to work but too hard and it gets scratched, it gets the hairlines out. Been printing a long time and never heard of goose quill brush, does someone still make them? Dick G.

As others have pointed out, those mats that create “hairlines” are shot. They only get worse with continued use and slowly damage any good mats that they come in contact with. If you look carefully at anything that was printed on letterpress (using type set on a Lino), you will sometimes see small hairlines. When I first started working on a Linotype (1978), we had some fonts in our shop that were full of hairlines. We used a goose quill brush to remove them, but you can damage the type if you brush hard enough (it rounds the sharp edges of your type a bit). On larger point sizes, I would occasionally use an Olfa knife to carefully cut hairlines from between letters. You need sharp eyes and a steady hand to do this (and obviously you could only do this on a few slugs, not a book). I can still remember how happy I was the first time I pulled a proof that was set with a good font (10pt Alternate Gothic) bought from Don Black. NO HAIRLINES!

Our shop had a Linotype and an Intertype. We scrapped the Lino in the mid 80’s and sold the Intertype in the late 90’s. There definitely are days that I regret getting rid of those cantankerous old mechanical beasts. Sigh.

I have two new goose quill brushes won on ebaY in 2007. Thankfully most of the mats we have at linotypesetting.com are in good condition, so in the rare event, I simply take an Exacto knife and excise them.

Merle Langley, former owner of Marlboro Mats, which was the big dealer in 2nd hand matrices before he sold to Phil Driscoll (who no longer deals), is said to have tweezed sidewalls straight on mats that were hairlining, and would run through entire fonts resuscitating them.

I’ll be in the shop setting a book next week and will take a picture. It shouldn’t be difficult to make a brush up from scratch by those who need.

mjb / interrobang letterpress / linotypesetting.com

12 point Garamond is a font that you should be able to purchase.

Mix the two fonts, but remove ALL worn out mats that have bad side walls. You will see typemetal on the side walls of the worn out mats. Those are the ones to scrap.

As many have posted, space bands and mat should be kept clean. Many shops, forget that Linotypes and Intertype need to have their mats, magazines, space bands etc kept clean.

Over the years, I would go to a shop to help set type. Some keep their machines and mats, space etc clean on a weekly basic. Others NEVER kept their equipment clean and getting one line of type out of the machine was hours of work.

goose quill brushes:

http://www.flickr.com/photos/interrobang918/6337701723/in/photostream/