Adana HS/2 ink Disk not catching/rotating.

Hi,

Hopefully I’ve posted this in the right section.

I’m totally new to printing, picked up an old Adana HS/2 which I’ve been gathering parts for, just fitted the ink disk and although it’s sat right down in the hole, the ratchet isn’t connecting properly to turn the disk.

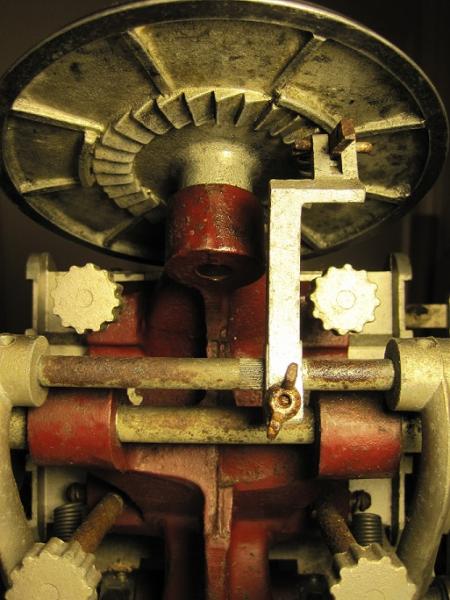

I can’t move the ratchet further over because it seems to be keyed to a grooved part of the shaft it’s mounted on? Hopefully that’s visible in the picture.

Also, is the ink plate supposed to turn freely, if you turn it by hand - mine seems really stiff and I’m wondering if it needs a cleanup/oil?

I’d be grateful for any advice on this!

Thanks.

adanapress.jpg

undo the wing nut and move the arm toward the front of the press a couple of deg , the grooves are there to give something to bite to not prevent you moving it once un done .

Oh yes oil is usually required on as many moving parts as there are ,these little things are made with no proper bearings so oil is very important.

The little bit with a point that pushes the disc round should have a bias that make the pointed end tip up in the air and then when the plate is in place the disc sort of holds everything in the correct position for the component to act as it should !

Sorry for the delay in replying, thanks for the info - I’ve had a look at it again this evening and the disk is now rotating freely after much oiling and reseating, but the ratchet still seems way off.

Do you know if the ratchet arm curves away from or towards the front of the press? I’m wondering if ours it fitted back to front as I can’t move it any further over without the arm fouling to centre of the press.

Thanks.

The ratchet as described is a pawl , can you not make one that will reach ,do remember though that the blunt end acts as a counterweight to keep the pawl pointing upwards . Having a look in the morning at one just to see if i see an answer .

Looking at the picture you have everything in the right place. The pawl is a bit of a pig to set right on the High Speed 2, I’ve got 2 of them. Evidently somebody has had a problem in the past as they have fitted a wing nut. If the arm is too far forward it jams under the disk, I adjusted mine by unscrewing the nut at either end of the spindle and and then turning it into position and then doing the nuts up.

Your press looks a bit of a state. Rub the bare metal with fine abrasive paper and oil the metal and all joints with light oil such as sewing machine oil, not heavier motor vehicle oil Anything steel you can get off, rub down and drop in lemon juice. The 4 adjusting screws will clean up but don’t leave too long in the lemon juice as it eats the allow heads and you get a grey mess.

As already mentioned the High Speed 2 needs a regular light oil especially around the disk spindle and on the arms and arms springs so the arms don’t stick as the rollers go up over to the disk.

Both of mine are the heavy iron H/S and not the lighter H.S.

The High Speed 2 is a good press better than the Adana H/S 1 (a toy) and the 5x3 (too small), usually the cheapest of the Adanas on e-Bay in the UK.

Thanks again for both your replies, yes it definitely looks like someone has modified it somewhat and the counterweight is not able to move the pawl freely at the moment.

Good to know everything’s pointing the right way though - It really was a mess when we picked it up so I’m going to take your advice and give the whole thing a good cleanup/oil and see what I can do from there.

I’ll no doubt be posting back with more questions following that!

Thanks.

Just to come back on this - I decided to strip everything down and clean it up as advised - re aligned the ratchet arm and put a slightly smaller split pin through the pawl and everything’s working fine now.

Thanks for the assistance.