Amateur Mistake Inking Problem

Hello Folks,

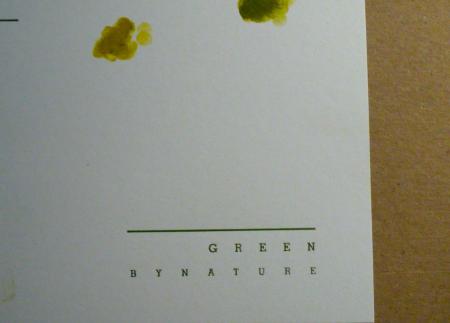

I’ve been printing for over 30 years. This week I had an inking problem and realized I’d made an amateur mistake. Typically I mix my own ink colors, using VanSon Rubber base ink. I often start with opaque white, adding colors as necessary to reach the shade that I am looking for. Last week I mixed a green using the white, yellow and reflex blue. When I put it on the press I realized something was very wrong. The ink would not print evenly. It had lumps and the ink lay was very inconsistent. (see photo attached, rubber oil mix) Turns out the yellow was from an old oil base can which I have now tossed.

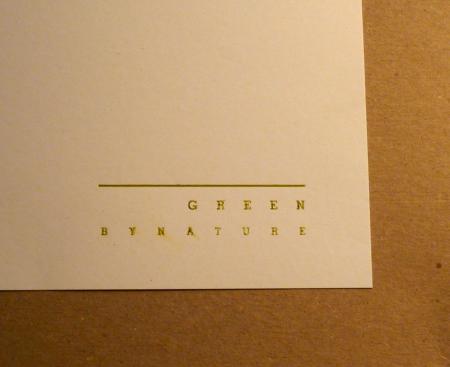

I remixed an new batch using only rubber based and had a similar problem. I mixed a third batch (see photo rubber only, no white) and had a similar problem which you can see in the photo.

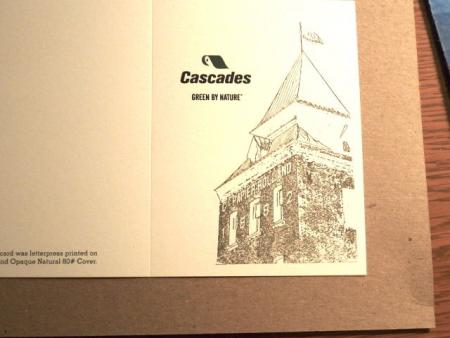

The third photo is a something I printed the previous week using the same rubber based ink. In fact the green is made up of the opaque white, yellow and reflex blue, with a small amount of black. (all rubber based) The brown was a mix of white, yellow and black.

So what caused the weird inking problem with the ink.

I’ve yet to go back on press. Waiting to hear from the BP community.

thx

s

previous weekoil only.jpg

rubber only mix no white.jpg

oil-ruubber mix.jpg

Steve:

Have you changed anything you use to clean the press? Even if it has the same label, does the cleaner feel the same, or does it seem “oilier”? It almost looks like there might be something getting in the ink which causes the pigment to separate from the varnish, giving a smeared appearance when printed. Perhaps something left on the press or rollers is getting onto the ink when you ink up the press.

By the way, you should be able to mix rubber-based and oil-based inks without significant issues.

John Henry

Cedar Creek Press

Back in the day, the foreman used to mix rubber and oil based ink together no problem…unless you were an unexpecting newbie. He would hold his hand over the mixed ink, loudly announcing to the shop, “it’s getting hot”…hoping that the new employee would hold his/her hand over the mixed ink to feel the heat radiating , so he could then push your hand into the rubber and oil mixed ink. I never bit on that one, or any of the other jokes they liked to play.

OK Folks,

I just finished reprinting the piece. It came out great. I tried everything I know how to do. I had washed the rollers numerous times. (Same press wash that I’ve been using for years)

I adjusted the roller heights (hours to no avail), futzed with packing, and then finally turned the cut 90 degrees in the chase and walllah!

I think it was actually like a slur. Although I had tried putting type high bearers in the chase that were longer than the cut so that the rollers would be rolling over the type when it got to them. Which usually helps -but did not in this case.

Maybe the ink wasn’t mixed well enough, so that being rolled out for some time on the ink disk helped. Any thoughts?

s

You dont spray your open cans of ink with antioxidant for storage do you ??? Or worse for a pressman an oily sheet in the top of the can ?

Peter,

Some time ago I had something called Overnight Spray. It was intended to be sprayed on the disk and the rollers so that the ink would not dry up on the press.

I had used it a few times and the result was similar to the problem I was having. Basically it was like diluting the ink.

In fact I left the ink on the press for a few hours this evening and printed the last part of the job with the same ink and it work just fine and look real good. Go figure!

thx for your help, if anyone has any thoughts I’d like to hear them.

Anti oxidant ,is what you call ,overnight spray ,its a thin oil .

It causes less of a problem on a machine with a long ink travel but a tabletop hasnt got enough milling power to mix the spray in well (less rollers of course) it can cause a similar effect with the polymer plate ,it is not so bad with hot metal though .

I print very few jobs letterpress ,other than the stuff i print at the museum , i avoid the spray like the plague , in fact i am not even sure if there is any outside at the moment ,i only use it now in the cans of metallic ink to stop the skin from glassing (going brittle) and i havent touched the silver for months !

Girl w/a Kluge- If that happened to me, I probably would of punched the guy with my inky hand……then start looking for a new job:)

Yes, but if you were a girl, a slap would leave more ink than a punch lol.