wharfedale press paper return

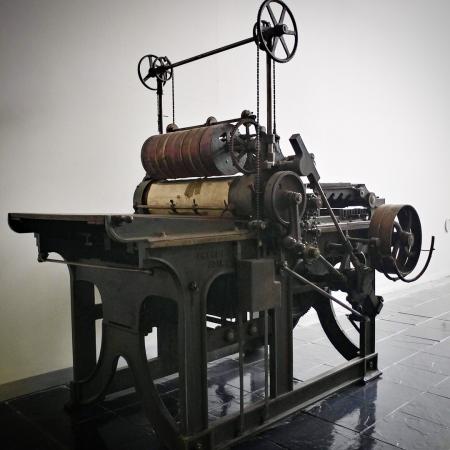

I am about to take delivery of the press illustrated below. I was wondering if anyone has any information or description of how the “gantry” mounted high above the cylinder is meant to work, or even more basically, what is it? I

I am pretty sure its part of the press’ paper return but just how it works is a mystery. All my searching has not shown up another one like it. There are other systems around, but just how this one is meant to work is not clear. The press has the usual wooden “flyers” but no indication on how they are meant to fit in with this overhead “gantry”. A search through Wilson & Greys book, with its excellent description of the Wharfedale mechanism has not helped.

Any leads, illustrations or photos of other presses with this arrangement would be greatly appreciated.

Ron

image2.jpeg

image1.jpeg

I’m not certain what the gantry is for, but I’ve got an idea that it is part of the mechanism that trips the impression in and out between sheets.

If you notice the chain on the larger wheel is attached to what looks like a 50lb counterweight….. one on each side for 100lbs of downforce. That downward force on the big wheel is turned into ~200lbs of upforce by the shaft and little wheels on the inner chain.

That 200lbs of upforce is lifting upward on what appears to be the tail end of a long trip-rod… that looks like it operates something under the bed (known as the “coffin” on some of these presses). My guess is that it drops and raises the bed between sheets, rather than tripping to cylinder in and out like more modern presses. I’ve seen a similar mechanism using levers, instead of chains on the counterweight.

Then again… that’s just a guess.

You may find more information in:

“A Short History of the Printing Press and of the Improvements in Printing …

By Robert Hoe”

available for free on Google Books.

That is a very cool press. Once you get it cleaned up an running, I’d love to see some pictures.

then again…. here is a link to a similar press where the cylinder is tripped:

http://www.briarpress.org/19262

now I’m intrigued….

I think the sheet is fed face-down under the cylinder, the sheet comes around and is transferred to the upper drum and then on the cloth tapes, with the fly fingers flipping the sheet off onto the delivery pile.

Hi,

I have run a more modern wharfedale back in the 60’s, as parallel_imp said when feeding a sheet through its the underside that is printed with the print on the top side coming off the printing cylinder and being turned by the delivery cylinder so that by the time it reaches the stick flyers and is delivered the printed side is upper most.

the gantry is to lift the delivery cylinder and tapes etc so that you can get to the printing cylinder for make ready.

I have a picture of the cylinder being made ready with the delivery unit raised and one of the press running, these pictures date from 1952.

wd2.jpg

wd1.jpg

Hi Frank,

I think you are right. I messed about a bit with the press the other day and could not find any way the paper return/flyers mechanism was moved up and down automatically in the press’ cycle. I then realized that the only way to raise that part of the press was to use the smaller wheel at the top of the posts on the near side. Once its raised there is a small pin that can be located in one of two holes beneath it - this would keep it up and out of the way, as you said, for make ready or for hand take-off.

On to the next problem - getting the flyers to do their thing at the right time. They are mounted on a spring loaded shaft, which I assume allows it to engage with the main cam driving the cycle. It has some adjustment so I will play with this to see if I can get it to engage with the cam. Re-synchronizing the two rollers is more straight forward as there is a painted arrow on the end of the return roller’s shaft. I just have to see if the arrow should point down or up when in synchro.

Ron