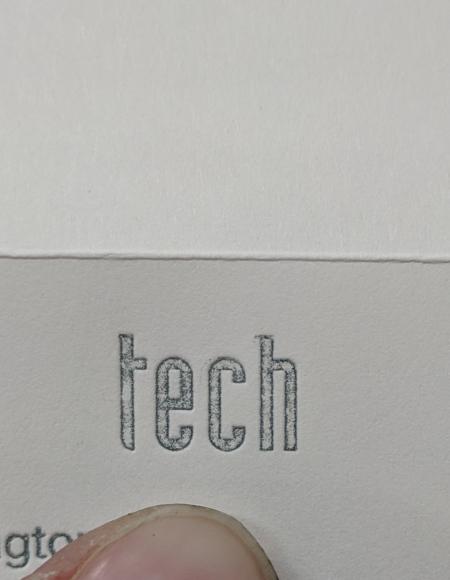

Ink Weirdness

Help!! Can someone please tell me what is going on with my printing? I am going loopy over here.

Press: Heidelberg Windmill

Paper: Cougar Envelope, though I had some similar issues on smooth cover stock and with a different plate.

I’ve tried two different mixes of ink..this is with opaque white.

I’ve remade the plate.

I’ve raised and lowered the rollers. This is with them raised too high but it shows the issue — why are the edges so inky? What is with the weird texture??

I think my rollers could use some help but I’ve successfully printed with them before!

Thank you in advance. :)

IMG_20190108_170610.jpg

i know you made a new one but, inspect your plate very carefully, under a loupe. looks to have been over pressured. Or maybe something is happening during development process to “dish out” the plate.

I’ve achieved similar results by having oil on my rag. Wiping the plate with an oily rag makes it impossible to lay a smooth coat of ink on the plate.

Bppayne, you might be on to something there.

I’ve cleaned and aired the press several times since this issue started but I am still concerned that somehow oil/residue is getting into my ink and causing the issue.

I put the same ink and same plate on my tabletop Kelsey and got a nice clean print, so I know it is possible. I’ve also put other plates that previously printed well on my Windmill and had the same issue/appearance.

I am cleaning with Kleen Strip mineral spirits. Should I be using something else? Is there anywhere else residue may be hiding? Can I treat my rollers with something? (I ran Putz Pomade last night, which did make my rollers LOOK refreshed..but no change in printing.)

Sorry for all the questions, I’m just stumped!

Oops, double post! First time that’s happened for me, ha.

Sorry, I’m very hard on my rollers, I use Varn Press Wash to washup. If there’s any residue left I use type wash or white gas on a clean rag and give it a quick wipe down. I’ve heard that last step is unnecessary and can eventually dry out the rollers, but it’s really a fast way to get to the next color. Mineral spirits should be fine, just make sure the rollers are completely dry before adding ink. Make sure your roller tracks are completely clean and dry also. Good luck.

AnnieW, might want to wash your clean press with damp rags, then let it run dry. See how that works sometimes different solvents and cleaners leave a residue that mixes kn the ink and causes issues. I know on offset presses this can happen. A good way to tell is a clean press running add water just a few drops if you see a white liquid form on the press rollers at the nip , your not clean enough scrubbing down with clean wet rags will usually fix the problem. When it is the water at the nip points is clear your good to go! I’ve had it happen on 36” offsets and my 42” two color Miller letterpress. Good luck!

Annie-

If all else as above fails, give your press and any roller contact points- as well as the rollers themselves- a wipe down with Acetone. All the steel riders, and even the drum if you can. Turn the motor off, engage the flywheel clutch, turn the press over by hand to slowly and methodically clean the large steel drum, and then clean everything else in the ink train too.

Repeated use of acetone will dry out the rubber of the rollers; however, a couple of wipe downs is not going to end the useful life of the rollers prematurely.

If you have a residue or oil problem you may be able to note where it’s coming from with a new freshly degreased set of rollers, and a bit of running time.

Thanks for the tips, everyone! I will try them over time.

I managed to get through one color on the job and the second color printed better. I don’t think ink was the COMPLETE issue, since the grey ink worked fine on my Kelsey, but it was clearly part of the problem.

We’ll see what happens as I keep printing new stuff!