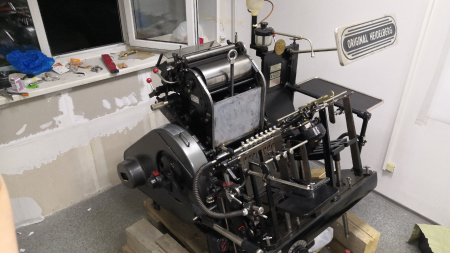

First Windmill in Siberia

Hello everyone.

Finally we got our windmill. We had to bring it through the window, so now we are doing repairs. Since this windmill is the only one to the East of the Ural mountains we have problems with availability of spare parts and specific consumables. We are new to letterpress and therefore have a huge number of questions. I am going to visit Europe in October and I would like to ask if there are some European analogues to Boxcar standard base which I can purchase in Germany?

We also got 2 chases with the machine and they are of different shape. What are the difference in use?

And another question is there somewhere a video or book which step by step explains how to work with the windmill? Or maybe it is possible to make a short visit to some print house in Germany (or France, or Italy) to see some basic printing routines?

Best regards,

Valera.

windmill.png

chase.png

With regard to the chases: the thinner walled one is called a “skeleton” chase and is meant for printing oversize Images, but does not provide the lockup strength that the normal chase does. Go easy when tightening the quoin keys.

Boxcar has some great instructional videos, and manuals too.

https://www.boxcarpress.com/letterpress-classes-videos/

Hang on to that skeleton chase, it may come in handy. Some jobs just need that extra little space. It looks like you have a nice press, you’ll love the lockouts. Maybe Heidelberg Sales know of someone near that could help you learn. Good luck!

Thank you for your answers. Regarding the frame I noticed that the one on the left fits perfectly into windmill but the skeleton one gets stuck at the bottom when I try to put it in place and it is hard to get it out.

OK, but it fits, right? Try cleaning it and the 2 posts it sits on. I always load my chases from the front, so I go squarly in and out. Side loading from the flywheel side does not work as well.

Sticking chases is a common issue. However it means your forms will not shift during a run. The machines were made very “tight”, part of why they are still so valued today.

Ok smart guys answer this. I could be wrong, but it looks like an installation hook is still in place sitting in the middle above the case area. This should be removed now if it is. The first time you turn this on I think you might break something, not good on a new press. There are also some good books you might find as downloads that will help you get started.

Good catch western411! Wow, that’s an accident waiting to happen!

Hello Valera, where did you buy your press? Do you know by any chance the type height? If you can communicate that, it would be useful. You have to look more at continental Europe then at the USA for parts and materials, some useful addresses follow here:

https://drukwerkindemarge.org/berichten/

Website of the Dutch private press association. Every day at 12.00 new advertisements are being published.

https://www.bleisatzmagazin-rheinland.de/shop/magnetfundamente.html

Bleisatzmagazin Rheinland (Germany), often sells magnetic bases, to German height.

http://drucken-und-lernen.de/Waren-Bestellung.71.0.html

Drucken und Lernen (Germany), for inks, tympan paper, spatulas, press wash etc.

Good luck!

Hello Valera, where did you buy your press? Do you know by any chance the type height? If you can communicate that, it would be useful. You have to look more at continental Europe then at the USA for parts and materials, some useful addresses follow here:

https://drukwerkindemarge.org/berichten/

Website of the Dutch private press association. Every day at 12.00 new advertisements are being published.

https://www.bleisatzmagazin-rheinland.de/shop/magnetfundamente.html

Bleisatzmagazin Rheinland (Germany), often sells magnetic bases, to German height.

http://drucken-und-lernen.de/Waren-Bestellung.71.0.html

Drucken und Lernen (Germany), for inks, tympan paper, spatulas, press wash etc.

Good luck!

sorry, double posting…

Dear western411 and bppayne thank you for your attentiveness but it was the first thing I checked that the pin does not intersect with the moving parts of the machine. Therefore, there were no emergencies for this reason.

Thomas gravemaker. I got my windmill from Mr Vogel from Germany. My windmill serial number has an N in it so the type is 23.56 mm high (AFAIK it is the French type or German?). Thank you for the links.

” I checked that the pin does not intersect with the moving parts of the machine. Therefore, there were no emergencies for this reason.”

YOU WILL HAVE A PROBLEM WHEN YOU HAVE ROLLERS ON THE PRESS AND THEY ARE NOT IN THE LOCKED POSITION THERE IS NO WAY THEY ARE GOING TO GO PAST THAT INSTALLATION HOOK

I would remove that before I tried turning over the press with rollers installed.

Don’t worry, the situation is under control :) The hook was successfully removed. In addition, we made the base of duralumin alloy (D16T alloy) 22,51 mm thick and 0.95 mm test plate.

windmill1.jpg

Hello Valera, German and French height are identical. If you want to work with type, this might be useful as you can buy type in most (but not all) European continental countries

(be aware of Dutch, Belgian, and Italian height for instance).

Working with type is interesting, but I’m afraid that I can not find Russian type anywhere. I don’t even think it exists.

Are you looking for type that was made in Russia, or are you looking for Cyrillic type that was made in other countries? If that is the case, Rainer Gerstenberg in Darmstadt (Germany) can supply you with the Cyrillic type!