Roller Placement on Windmill GT (13x18)

Hi Everyone,

I recently bought a Windmill GT, which I am determined to bring back to health.

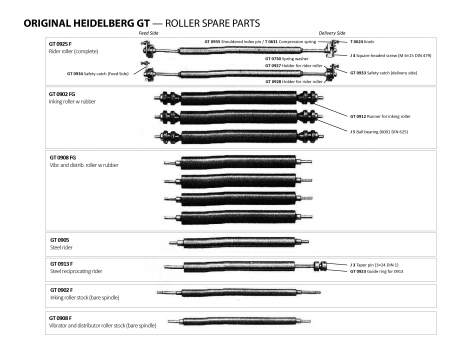

It came without the two steel riders (specifically GT 0905 Steel rider & GT 0913 F Steel reciprocating rider) and the four Vibrator and distributor rubber rollers (not to mention the three rubber form rollers (GT 0902 FG)) (see image). I have been able to find all the riders and rollers.

My question concerns the placement of the 2 steel riders and the 4 vibrator/distributor rollers. I have been unable to locate any roller/rider placement diagram or image for the Windmill GT that shows where they go to ensure an ink train to the large ink drum.

Would anyone be able to take a top-view photo of their Windmill GT for reference or specify the placement?

Any help much appreciated!

All best,

Christian

gt_rollers.png

topview.jpg

I realize now that the roller image might be too small to view, so I’ve uploaded a PDF of the image here: https://www.dropbox.com/s/0lcrrv9hna0l2wf/Roller%20Spare%20Parts.pdf?dl=...

Christian

In case someone encountered the same issue that I had, here is what seems to be the correct roller placement on the Windmill GT that will (hopefully) establish an ink train ;-)

otherside.JPG

rollerplacement.jpg

I don’t have a GT so you have a greater number of rollers than I do. The thing I see that is odd is the very top rubber roller on top of a chrome roller that looks to touch another chrome roller. I would expect soft to touch chrome not chrome to chrome - so sft in between the two chromes. BUT I may be wrong

w411 is right on there. The two rollers at the top of the pyramid are reversed.

My other comment is the soft roller that makes contact with the ink chrome ink tray roller. I cant figure out how that will spin if it is clamped down and wonder if there is or should a collar on the end of the roller like the other rollers have.

I have other presses where the fountain ductor (or vibrator by Euro terminology) roller has a locking retainer over the shaft end, but it doesn’t prevent rotation. Without it, the roller might lift up out of proper contact because of the rotational forces on either side.

Looking at the roller information, ductor and distributors are a common shaft. That allows you to shift rollers around, so you wouldn’t have a damaged roller in the critical ductor position. Otherwise you move better rollers closer to form, best roller being the last to leave the form, or # 1 roller as I was taught, though I had a roller salesman who numbered rollers with ductor as # 1.

Ah, very good points everyone! Thanks a million. Especially the chrome-on-chrome part: they clearly need to be swapped.

With respect to western411’s comment “I cant figure out how that will spin if it is clamped down and wonder if there is or should a collar on the end of the roller like the other rollers have.” I, too, was wondering about that - especially as I’ve had to have the journals/collars manufactured (I had to AutoCAD and have extra GT journals made, so if anyone is in need of some and have anything they wish to trade, let me know - or you can have the AutoCAD’s for free). It spins fine, and there’s actually no room in that roller position for a journal - but it had a small sliding lock that holds the spindle in place as it picks up ink from the well.