Thoughts?

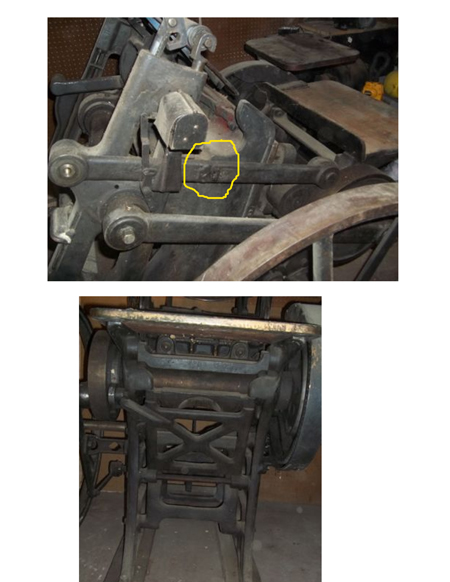

I have attached a photo that the owner describes as: “a repaired (brazed) pitman arm”. A few questions:

1. should I not even consider this new style c+p?

2. I am also wondering if anyone can tell from the second photo if a treadle can be added to this press, or if it is a later press that may be equipped with a straight flywheel shaft and I would have to have a different shaft?

Thanks for your help!

New StyleCP.jpg

Bearing wear notwithstanding, the arm should be pretty easy to replace - you just need to find someone who parts out broken presses.

had the exact same arm welded on one of my 10x15’s, the press worked fine, if your shaft is straight you won’t be able to use a treadle, if there is a crook in the center of the press it will accept a treadle.

Its hard to see in that second photo but it looks like there could be a kink in that shaft as if you look in my dodgy diagram below, the shaft disappears which “should” mean its kinked in the middle, but don’t let my comment be a decider. Probably best just to ask.

shaft.jpg

Like “dickg” and “D and d” said - if the main drive shaft is straight, no treadle - there needs to be a “U” to hang the treadle hook. But you can always get a speed control for a motor…

Thanks everyone! Here is another photo which seems to answer the treadle question… No treadle comes with this press, but here is the “U” shaft. So… I can have one made. Looks like the previous owner had a quick fix for the rollers (double saddle), but the other side has no “thin metal wire” to hold the rollers, so when the flywheel is turned the rollers pop out. Am I being too picky and this would be an easy fix for me? or will it be a problem with inking down the road?

I could not find this “Bonus Part” on my C+P diagram. Any

thoughts on what it is!? Thanks.

ExampleSheet.jpg

If i were you i’d take the one wire you have to the hardware store and find a wire the same diameter. can’t figure out your bonus part, it might go on the back of the press, a picture of the back might help.

Here is a link to the parts list for C&P New Series. That bonus part looks like the back throw off connect. http://www.boxcarpress.com/community/manuals/cp-newseries-parts-list.pdf

Doesn’t look like much of a problem - machinery of a certain age typically has had “adjustments” made to the original design.

HI,

The bonus part is the throw off connect. The wire can be made from the hook that normally goes on the float in the back off most toilets. The float is the part that governs the on/off for the water level. The part is sold by itself in the plumbing section of Orchard Supply and Home Depot. I seem to remember that I had to enlarge the hole very slightly with a drill. This part even has a curled end for gripping.

It does look like there has been considerable wear to the saddle with the wire. You may want to make certain there are no burrs that are catching the roller shaft ends as they rotate in the saddles. It appears that there was a bit of neglect in oiling these saddles or the roller ends must have been quite rough to get that kind of wear.

That being said, I have seen presses with more wear than this that were fully functioning and capable of fine printing. It just shows something the you should watch in the future, and take care to check out the other wear point on the press to see if lubrication was done on a regular basis, or is there a lot of wear overall.

The terminology is a bit confusing as im U.K. but the saddle as you call it carries the rollers ? If this is the case are they steel , brass or phospher bronze ? If they are steel then i would fill them with weld re drill and put bronze inserts in them that way the inserts wear away not the roller ends !

As an extra note you superglue the inserts in then a few light taps with a hammer gets them off when they too worn !