Spherekote

Has anyone ever used this Minnesota Mining and Manufacturing / 3M product from years ago on a proof press or other type press as tympan/drawsheet?

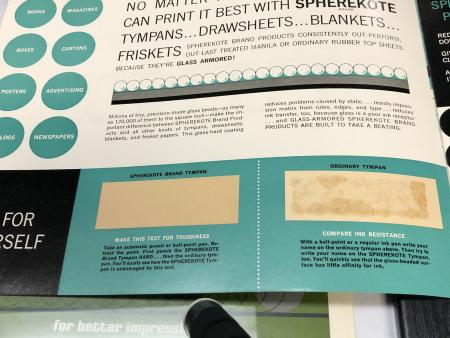

Here is a book snippet. I have an old 3m marketing brochure for it as well.

https://books.google.com/books?id=CplaAAAAYAAJ&q=spherekote&dq=spherekot...

I first heard of it from Cronite (engraving press manufacturer) and it was sold as a wipe pad accessory for $$$$ per SqFt.

There was a oiled tympan type version in 3 calipers and two rubberized versions somewhat similar to kimlon or perhaps an offset blanket which is basically indestructible.

The Spherekote advantage

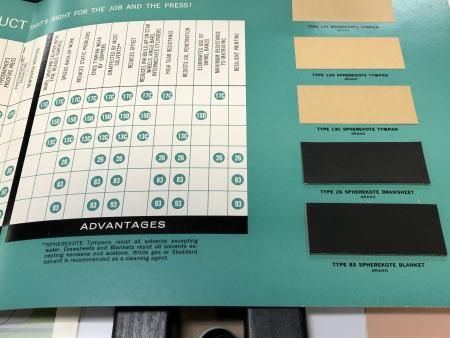

Spherekote types

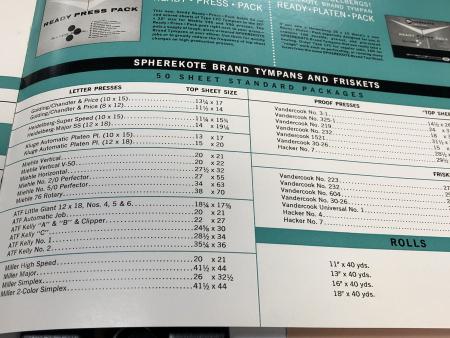

Spherekote standard press sheets

Yes, I have used it for the tympan sheet of the second cylinder of a perfecting rotary press ( a German Rotaman perfector ) back in the late 60’s early 70’s here in the UK.

It was used to stop the wet ink printed on the first side of the sheet transferring to the tympan of the second unit. In addition to the spherekote there was an application of a light oil/spirit to the spherekote to help stop any ink transfer.

On the older Miehle perfector presses they used something like a heavy onion skin material for the tympan on the second unit with an application of the same oil/spirit mix again to stop ink transfer.

The sheet size of the Rotaman was about 35 x45 inches and was printing from flexible plastic plates that had been made from linotype pages, some times including line and tone images.

I have used spherekote on platen presses, and as Frank indicated, it was good for work and turn work as ink transfer was limited by the resistance of the top coating to ink adhesion.

John Henry

Cedar Creek Press

When I bought my Goss flat bed newspaper press in the 70s spherekote was used as the tympan is on a windmill. I still use it today and it works great. 1000s of impressions without changing. Do be careful when adding packing to platen. Three points is plenty. Bob Mann,

Thanks for the comments. @highlandsprint, I agree it is tough as nails. I would guess we have a few hundred thousand wipes on our engraving press that we have used it on. But, if you can find it now it is expensive! Cronite charged $785 per yard on our last go at it.

I would love to stumble on to a roll of the rubberized stuff.

I am amazed it is still available, would love to try it out on my windmill. Does anyone know where to get it from?

Back in the early 1970s the newspaper in Colebrook, New Hampshire, had a Goss flatbed newpaper press, Model A. Spherekote was the top sheet, coupled with underlying felt, cork and tympan to comprise the packing for both top and bottom impression cylinders. A tech from Goss Co. would actually show up once a year or two to replace packing on that monster. 4 pages abreast on each bed at 22 inches per page. So the imp. cyl. was over 80 inches long, I think. Been a long time.

We used Spherekote sheets on our offset equipment for many years as an anti-marking system. Worked great and lasted years. Used on transfer and delivery cylinders to prevent ink offset as sheets were delivered out of the press.

If anyone is interested I still have some sheets which I can cut to size for whatever application you want to use them for.

Back in the 1980s we used to buy a 28 x 41” sheet for $83. About 4 years ago same sheet was in $400 range.

Feel free to call with any questions or if any interest.

Thanks

Larry Lionetti

516-633-5107 cell/text

[email protected]