Large Break on Press

Hello All,

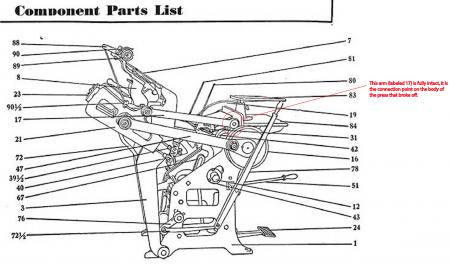

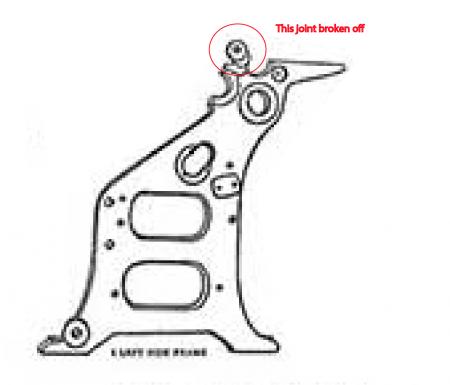

I am an art teacher and printmaker and my school received the 8x10 C&P press below as a donation. It has a large break in what looks like a very tricky spot on the flywheel side of the press. Because the break is connected to a very large piece of cast iron that makes up the whole left side of the press (not the arm, that is intact), I cannot tell if this break could be welded or if this press is damaged beyond repair. We don’t really have a budget for a huge and costly replacement. Any insight on whether this break is fixable would be so appreciated. -Sarah

Press break diagram 1.jpg

Press break diagram 2.jpg

Break 1.JPG

Break 2.jpg

Break 3.JPG

Sarah:

I think it is likely that the break is not ideal for welding. You could give it a try, but it really should be brazed, and that is difficult “on location”. If it were a rare press, you could take it apart and have things done correctly, but chances are it would take more time and effort than the press is worth.

You would not want to have the weld fail while a student was hand-feeding the press.

I think if it were mine, (of course I’m not hampered by University regulations) I would strip it down and sell the parts, perhaps raising enough $$$ to purchase an operable 8x12 press. There are quite a few around, and not very expensive.

John Henry

Cedar Creek Press

Sarah,

John has a great idea. There is always a need for parts, and like many cars it may be worth more in pieces than as a whole. As John says presses are out there, depending on where you are located you might be able to pick on up for just the cost of hauling it away. Again, depending on where you are, but I’d start by reaching out to John Barrett at Letterpress Things in Mass to see if he has any presses in stock, or is aware of any coming on the market. They seem to pop up on Facebook letterpress sites all the time. Good luck, Steve V.

Flywheel-driven platen presses are a bad fit for a school due to safety concerns and OSHA regulations. I would suggest letting this one go and putting out feelers for something safer like a hand lever platen or a proof press of some kind.

DGM

that’s an odd place for a break like that. it could certainly be repaired either by brazing or careful welding ( you would want to vet the weldor beforehand), might have to remove some parts to do it. if it were mine i would either try that or look for a press being parted out, and replace the whole part. it looks like a nice press otherwise

Most common place for a break on a C&P open. This is the Achilles Heel of the roller arm side of the frame. I have seen at least three of ‘em with this break, brazed, and have owned one (a 10x15). They have a tendency to re-fracture at or next to the fix. If fixed, the parallel axis to the shafting on the press must be carefully maintained, or the arm will bind, placing a great load on the pivot, subsequently re-breaking it.

Interestingly, on C&P Rice Feed (Craftsman) presses, this pivot is on a separate casting, along with the starting control and delivery table support, securely BOLTED onto the main frame, and is more heavily constructed.

On the press in the picture, if it were my machine, I would see if a machinist could gingerly bore two holes and either pin or bolt it back onto the main frame, with an application of superglue on the broken faces.

Frank.

Another option is a system called lock n stitch. Ive used it before to repair broken cast iron parts. No heat involved and if done right the joint is stronger than the original parts. Would have to inspect the parts closely to see if there is enough cast iron and how the break is located to see if this would be an option. Marshall

That piece operates the ink roller cycling. You could still use the press by inking with a briar by hand. slow, yes, but doable, yes.

Interesting, I’ve not seen a break there, but have seen the actual arm broken several times- my press had a repair there- caused by the reddington counter slipping on mount and crashing the press.

I’ve seen this on presses pounding type into thick paper, and I have also seen it from die cutting with too much pressure.

Regardless it’s usually from asking a c&p to do too much.

I suspect but have never seen it happen that a work up could cause this sort of over pressure

Thank you all for your very helpful input. I believe I will pursue the option of cold-stitching/Lock-n-Stitch and see if this is a good fit that would provide enough strength. The press is in otherwise excellent condition and it is very difficult to imagine it getting scrapped.

Does anyone know who to reach out to for cold-stitching/Lock-n-Stitch processes for repair? Or is it possible to do this yourself? Wondering if machinists or some other title would have expertise in this type of repair.

http://www.locknstitch.com/ for more info on Lock-n-Stitch.

See what they suggest, best, Bruce