removing flywheel - C&P New Style 10x15

I am partially disassembling this press for a move and am seeking some advice on removing the flywheel. Can anyone here with experience with this comment on the best approach?

It seems that there are two approaches.

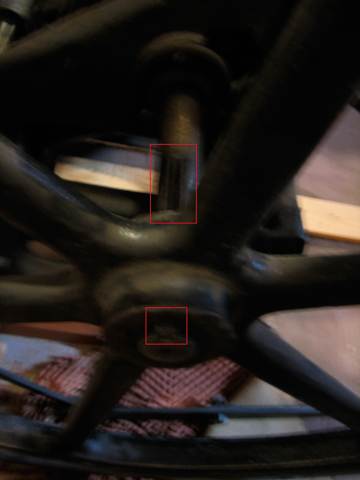

The first and easiest seems to be to remove the pin on the outside of the flywheel. Should this be removed? If so, any suggestions for the best technique and tools to use to push this out from the inside of the wheel? It’s at an awkward position to hammer out from the inside (see image IMG_2455_rev.jpg, sorry for the poor picture quality)

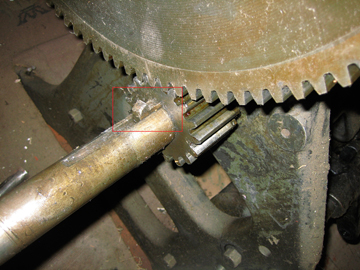

The other approach seems to be to remove the pin on the other side of the press on the gear/cams and slide the flywheel shaft out of the other side of the press. If this is the best approach, are there any suggestions for removing this pin as far as tools/technique go? It didn’t seem to want to move. (see image IMG_2473_rev.jpg)

Any insight into this would be appreciated.

Thanks so much.

Joshua

IMG_2455_rev.jpg

IMG_2473_rev.jpg

I’ve found that it is much easier to remove the key of the pinion gear (the one in your second picture) than the one of the flywheel. You can see a lip that you can use on the end of the key. Either use a slide hammer or drive a wedge between the lip and the gear. I’ve also seen a long iron bar lever used to jerk the key out, but that seemed a bit prone to mishap and we had to look for the key across the room when it did pop out. If there is room you can try to push the pinion gear in toward the side of the press to help loosen up the key. Easiest way is an iron pipe that will fit over the shaft and key so you can use indirect hammering on the end of the pipe.

After you get the pinion gear off, there is a plate on the flywheel side of the press with three screws. Take out the screws and an oval hole is revealed. Rotate the flywheel so that the hole lines up the offset crank in the shaft and pull the flywheel out with the shaft as a unit.

But before you take anything off; Are you sure you really need to do this? Removing the flywheel won’t buy you much in either removed width or weight. If the move doesn’t involve narrow doorways or corridors or stairs you might be able to just jockey it through whatever. With a couple of sturdy skids under the press and a few 1” iron pipes under the skids you can push this around almost anywhere you have a firm surface.

Thanks again, Arie, for your information. I’ll continue with the pinion gear key approach. I do need to remove the flywheel as the press is being moved up fairly narrow stairs out of a basement.

Just FYI, most C&Ps are actually (depending on a few accessories) narrower in the closed position sideways going though doorways than it is wide…..

And when trying to get a flywheel off…. good luck! lol Remember everything is either cast iron or VERY mild steel, and the smallest distortion will prevent it from going back together…

Thanks, Dale. We do need to remove this flywheel to get this up the stairs.

Any additional ideas on removing this pinion gear key (see second picture above)? This pinion gear key has proven very, very stubborn.

Today, we tried the iron pipe approach over the shaft and key and hammered the pipe indirectly to try to push the pinion gear inward thus freeing up the key. We’ve also tried and iron bar lever to try to pry the key out. No luck in any of these attempts.

If we end up having to drill this key out, I’ll certainly be in the market for a replacement key. Does anyone happen to know where I might find an extra one?

Thanks for your assistance.

Josh

Josh:

Try soaking the pinion gear key with Kroil or some other penetrating oil overnight and see if that helps.

A metal wedge driven in between the lip of the key and the pinion gear is another method.

If all else fails and you have to drill it out, the key is a pretty standard size key. Replacing it shouldn’t be hard. Not ruining the keyway of the gear in the process is harder. I had a key made in a machine shop before I found out they were a standard size and it didn’t cost more than $10 as I recall.

http://www.mcmaster.com/#catalog/115/3303/=1fy0t2

yours i believe is 3/8 in square. it does have a taper. it is i recall 3 in long. be careful in drilling this as alignment is important. you will find this key quite tenacious as almost all metal must be removed before the key gives up. maybe call around to some machine shops in your area to see if they have a “gib head” key puller. too bad you’re not in the milwaukee area as i have a key puller made specifically for this key on this press. it is a slide hammer type and works great. i would work the slide hammer angle above all other options.

+1 on the Slide hammer, but make sure you get a nice one with a sharp hardened steel lip on the end, otherwise it will round off your key in a jiffy. I made mine out of scrap metal for about $10

I would also consider heating the gear (keeping the shaft cool) sort of the reverse of how the shrink prop hubs on airplane crank shafts…

The less beating on the pieces you have to do the better!

Thank you! I will try these options this coming Saturday. I’ll look forward to answering more questions on Briar than I am asking now. With time, that is. :)

Thanks again.

Josh

Success! Today, we were able to remove the key by using a metal wedge and sledge hammer. Thanks again, everyone.

Josh

Hi Josh! do you have an riugh idea about the weight of the flywheel? I need to remove the one of my os 10x15 c&p, and i a i’m afraid it’s too heavy for me.

Any advice?

Thanks!

The wheel is pressed on to the shaft

The proper way to remove it is with a puller

Good luck

James ‘Mac’ McGraw