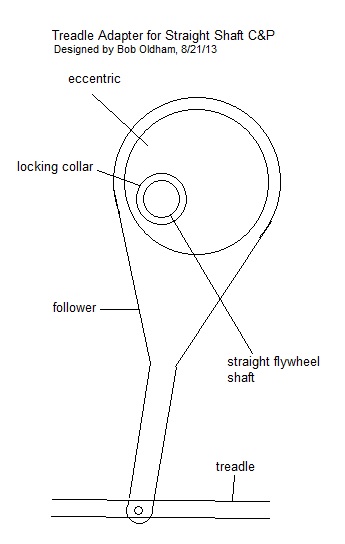

Treadle adapter for C&P straight shaft presses

This problem keeps coming up and today I came up with an idea for a device that could solve the problem. If someone were to make them up in advance I bet they would be of interest to people who are buying later model C&Ps meant for motorized use.

Bob

Treadle_adapter_for_CnP_Straight_Shaft.jpg

Note that there will be a lot of friction on the system, and that the throw may need to be more that the 2” of a regular C&P to overcome this—Alternately a longer treadle/lever may provide the force to keep the system working. A large roller/needle bearing cage seems like it would help a lot—vs a plain bearing.

An oil cup on top too.

Really cool share and design, I like the idea of people like Mike inputting their thoughts to improve on this design!

A community design.

Split needle bearings on the inner and outer bearing surfaces of the eccentric would deal with the friction. Likely, that would have less friction than the original design of a steel hook bearing directly on a steel camshaft. A more interesting question would be whether there’s enough space in the guts of the press for the eccentric since it’s bigger than the camshaft.

—

Michael Hurley

Titivilus Press

Memphis, TN