Help needed! Heidelberg KSB for diecutting - perforating

Hi everyone,

We recently purchased a KSB Heidelberg 40 x 57 cm 18”x22 1/2”. This is the first machine of that kind in our shop and we have no experience. I have read the manual and what Ηeidelberg is suggesting, commended with my questions, is listed below:

1. “Use a metal jacket .0315” with a .015” packing”

That’s ok I understand it.

2. “We recommend the use of steel plate under the form.”

I talked to other printers (among them the seller of the machine) and no one uses such kind of plate. I also talked to local suppliers (We are located in Greece) and they didn’t have any idea either.

Should I use such a plate and if yes what are the specs?

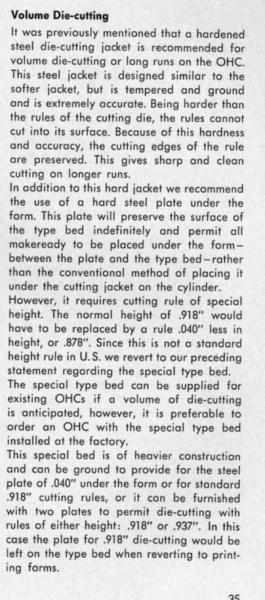

3. “Heidelberg states that the press can be ordered with a special type bed for die cutting installed on the factory eliminating this way the use of a steel plate under the form and allowing the use of .937” or 0918” cutting perforating rules”

How can I tell if our press has that type bed installed or not?

4. “Important! Steel rules for cutting - perforating must be .0918” high if no steel plate under the form is installed”

All printers I talked to strongly suggest .937” high. Which is correct?

Finally I made a test trying to perforate 300gsm carton: I fisrt used 0.897” rule with no result. Then I tried the .937” it left me with the impression that the rule cut the paper to deep. Unfortunately we do not have .0918 rules to try.

Now I am planning to special order .0918 rules because none of the local suppliers has it in stock.

Any help on what path should I follow would be appreciated.

Apologies for my long post but I am in the dark here with our new KSB.

Thank you.

Heidelberg_PressmanTips.jpg

I run the press before. It on my wish list, but the cost is out of my budget.

Have you run a cylinder press before? What presses have you run before?

What are using this press of?

Thank you for the post David.

I haven’t run a cylinder press before. We are litho printers.

The closest machine to KSB our shop has is an original hedelberg 25x35cm which I use for creasing, small die cutting and hot foiling.

The KSB was bought only for die cutting.

a

Mike, I appreciate your help and your advice. I will follow them as starting point!

How can I tell if my KSB is grounded to use .937” or not?

I will email you some images of the machine if that helps.

Danos

I believe that the different cuttingrules height s depended originally if the machine was intended for european vs american market this was mainly because of the difference between metric vs inches measurements same thing happened to offset presses because of the difference of the paperstock cutting rules comes in both heights i recomend to alway go for the lower ones were you can add pressure under the cutting jacket without need to have anything under the form

A

Danos in your case go with as close to .918 as available.

I don’t know how it is where you are, but from what I’ve seen in the US, if your KSB has German-language instruction plates around the press it would be .928”, and if the plates are in English it would be .918”. That is, if it is a printing press that has been stripped for diecutting. If built as a cutter-creaser there are other possibilities.

One reason for a bed-plate is to protect the bed. A previous owner of my KS scored the bed doing door-hangers.

Thank you all for your advices!

What I did is to contact with my local Heidelberg agent and ask for his help. He contact himself Heidelberg in Germany and hopefully, I will have an answer soon.. I ‘ll let you know.