Printing a zip lock bag/envelope on windmill

I’m looking for suggestions for printing these Zip Lock Bags

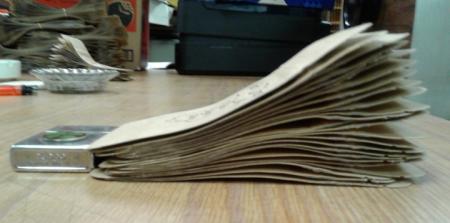

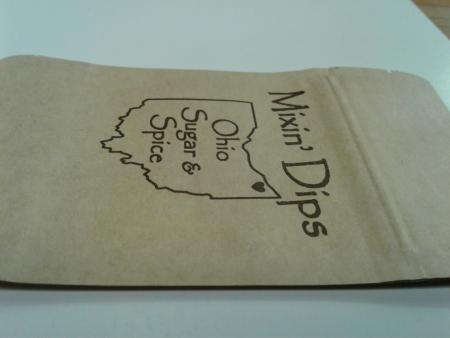

I have to grip from the zip lock end or my boxcar base will seal the closure. I have tried a big wedge and it is a big Pain in the butt. It seams I can only load 10 to 15 at a time. I have attached 2 pictures. The one is a stack of 25 bags the other is a single bag.

This is my first order for this customer and they want 10,000

2 sided. I grossly undercharged the quote because I thought I could load a whole lot more at a time. Any Ideas wwould be welcome

Bags 1.jpg

Bag 2.jpg

Mount your plate to a block of wood and shim up to .918 like normal (prior to boxcar) then grip bottom of bag. Same as reinforced tags PIA but does work.

Owosso will do a copper plate on solid wood (cherry). It’s worth the extra cost, they hold up better to doubles, etc. You need to ask for it, otherwise, you may get it mounted on plywood, which will not hold up.

Mike is right. This is a case where a full-size high base conflicts with the job. If the mounting material is sized to the image area, and normal furniture surrounds it, the bag closure is in the non-image area and won’t be affected.

You may be OK gripping it on the closure end. I would run it that way with a christmas tree. There’s more info on the attachment here on BP http://www.briarpress.org/30109. I’ve run one for tags and envelopes, it saves a lot of time. Hope this helps.

@donprints this may be too late but i’ve used https://www.roastar.com/ in the past. they have low MOQs and produce quality work at an affordable price.

You might try cutting a 2-3 inch tall block of chipboard. Cut it short of the length about to the bottom of the ‘M” and let the taller end of the bag lay past the end of the chipboard. Your bags might lay flat enough to feed and table should respond fine with maybe the odd hand crank .

Don, what did you end up doing with this order?

Well I got the job Done!

I ended up using a wedge made from a 2x4 with scotch brite stapled to the bottom and a piece of sandpaper taped to the feed table (so the wedge wouldn’t slide forward)

I bought the Christmas tree from Carl - 2727Printer

But it did not work well for this size 3x5 , It did work out great for for the 5x8 envelopes of the same style.

I’m not giving up on the Christmas tree though. I just got 2 more of the round rods to use for the side stanchions so I’m using 4 and and drilled and tapped a new hole in the feed table to mount the Christmas tree more centered.

Next time I’ll shoot a picture and post what it looks like if I get them to feed well

Windmill Christmas Tree.jpg

Great! Where there’s a will, there’s usually a way.