Vandercook bad rollers?

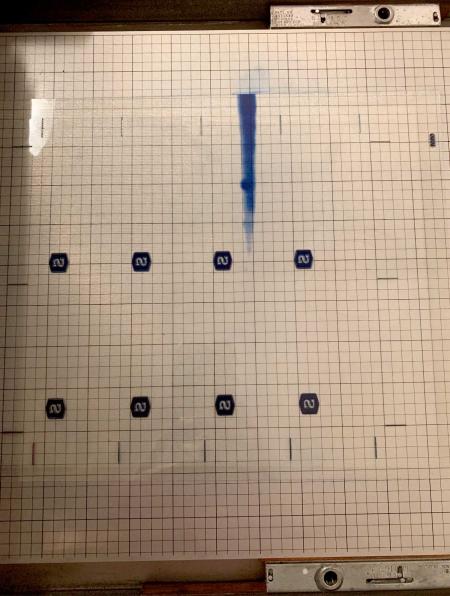

I had something odd start happening recently with my Vandercook No. 3. In one spot a little over halfway down the form (7 inches) the roller is making contact where there is no artwork (I am too tired to remember the name of the area of the form where there is no raised surface). But only on the left side.

The weird thing is that it doesnt happen in trip mode. The plate gets ink, no roller touching the lowered surface of the form.

I am using photopolymer and have had no issues until this. Adjusting the rollers seems to be futile.

I am banging my head against the wall trying to understand how this can only happen in one area. The rollers don’t appear to be misshapen.

Anyone had this issue and know how to fix?

screenshot.jpg

Update:

I have adjusted the rollers 20 or so times now and no matter what I do I cannot get consistency. The latest image shows where I ended up after lowering the form rollers from where I had them in the first image. Ink coverage is pretty good except for that one area.

Another thing to note is the roller gauge readings are wider on the outer sides of the gauge than the inner sides which leads me to think my rollers may have become swollen on their ends. I cannot really see it with the naked eye but the gauge doesn’t lie.

I have never replaced rollers on this press and am wondering what the process is and the best place to get new ones. Any advice is greatly appreciated.

Thanks,

Stacy

screeshot-2.jpg

I don’t mean to insult your intelligence, but are you sure the plate isn’t wrinkled up in that area, or that the plate wasn’t washed out as far down in that area?

Since the stripe in the non-image area is not in the middle, did you try rotating the plate 180 degrees and see what happens?

Deleted a double post

No insult at all. But no, the area is as flat as the other areas.

Hi Stacy,

I’ve had this problem on my #3 as well. I assume your #3 is galley depth, like mine, and I also assume (though I can’t see) that you’re using a bed-plate beneath the plate-base. As long as your gauge is the proper diameter with or without your bed-plate (either .918 with the bed-plate, or .968 without the bed-plate), I’d also trust the gauge. I’ll share how I trouble-shot, and also what might be happening.

To trouble-shoot (in the middle of a job with ink on the press), I would trip to ink the plate, then return the carriage to the feed-table, and lift the entire carriage before printing, since in my case also I would get banding on the plate when in print but not in trip. At the end of the print stroke, I would lower the carriage to re-ink on return, and then (if necessary) wipe down the plate before registering another print. I made it through a job or two in this manner, but it can be frustrating with the extra step, especially if you’re in a hurry and/or tired.

To offer a middle-range solution: I raised both form rollers as high as possible, and then slowly lowered, testing on the plate and with a sheet of paper the thickness of my stock almost each time I turned the form-roller screws 1/8 of a turn, to find where the plate got ink but the space outside the form did not. I found, especially on my #3, that polymer was more precise than my press (or perhaps more precise than me…), esp. with old rollers and an old bed-plate, too. So, while my gauge might have said the rollers were set properly, I would raise them a bit higher to avoid inking the non-print elements of the form. It looks like if you back off just a bit on the top side of the carriage in your first image, you’ll still get ink on the form but may avoid inking the plate.

My long-term solution: I got new rollers (NA Graphics and Ramco are both great), and I also seldom print from polymer anymore. Type has been much more forgiving. Good luck, and let us know what the problem turns out to be!

Andrew

Andrew,

Your assumptions were correct. Bed is galley height and I have measured rollers with the bed-plate in using the .918 gauge as well as without the plate using my .968 gauge and results are similar.

Your middle solution was similar to the attempt I made to get this job finished but I was getting uneven coverage from left to right, so I scrapped the job and am sending it out.

Your long-term solution is probably my best best but I hate to hear that you stopped using polymer. That’s a good bit of what I do and I have never had a problem in the past. Are you suggesting that the No. 3 is not a good press for polymer? I had never heard this (and after spending $8000 on it hope that that isn’t the case!)

Thanks for your reply.

Stacy

Sounds like you need new rollers. The Vandercook 3 is fine for all of your work. You can purchase from NA Graphics or Advanced Rollers.

Rollers tend to swell on the ends as they age and that tends to happen with in the first year regardless who makes the rollers. As you put more years on the rollers, it becomes more pronounced. The rollers should be set to the plate using the roller height gauge as the starting point. The combination of plate and base tend not to be precisely .918. And possibly the bearing blocks need to be looked at to see it the rollers are turning properly, especially if there is wear or slop in the block.

Fritz,

Thank you. It looks like I need to place an order for new rollers. You will hear from me soon.

Best,

Stacy

Yep, Thanks Casey!

Rippeon, your rollers should be at the same height in trip and in print. If not, I’d suspect misadjustment of the cylinder carriage bearings. (Lot of that going around from removing the cylinder carriage for transport.)

Hi Stacy, Do not buy new rollers yet, it may help but it’s not the cause of your problem. Your problem is a design defect in the #3OS. I will call this the 7” slap (for lack of a more technical term). The old style 3# presses were manufactured without a bearing forward of the ink assembly on either side of the cylinder frame. This causes a rocking of the cylinder when the carriage is coming down off the elevated section of the gear rack and on to impression. To be sure, ink the plate in trip mode, before you pull your first impression lift the ink rollers and print. If there is no 7” slap it is what I described above.

The newer #3’s have a forward bearing/bearer that can be adjusted to eliminate this phenomenon and make inking adjustments more consistent on and off impression.

I suspect it is mostly the forward form roller as it sits well beyond the carriage bearers. The far-side bearers may need a “tweak”, a very minor adjustment, emphasis on minor to eliminate this issue. Having said that, the far, rear bearer is a MoFo to get to.

S

Vandy #3 003.JPG_.jpg

Steve,

This feels right to me and would explain how I went from good to bad on a single job. When I am inking the plate in trip mode, the ink coverage is spot-on perfect—does not get on the plate. If I remember correctly, pulling a print with the plate inked, rollers up, no slap.

I guess I need you to walk me through it. And thanks for the response!

Stacy

Good info from smart guys above. Just wondered. I don’t have this press and cannot really help Is there packing in between the plate and the base. I see a shadow around the outside that is may just the photo. Also I do on occasion have this issue on photopolymer plates. I have found that the adhesive can dislodge when moving or repositioning a plate or if my base is not clean. Sometimes it is in between the underside of the plate and the top layer of the adhesive. It can create the effect of a bubble which many times I push it flat but it comes back. When that happens the can rise and come back on impression. I replace the adhesive and the problems always goes away. One quick check is to move the whole base. If the mark says in the same place the shot is the issue not the press.