Uneven inking on polymer plates

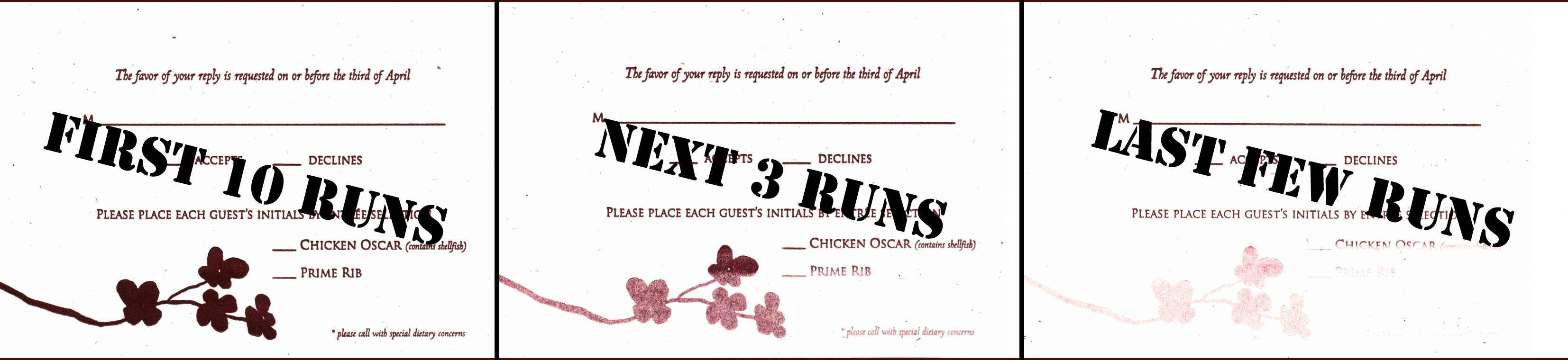

I’ve been reading threads and I’m not sure if this is the same issue others have been having. I’m using a KF152 plate from Boxcar with a deep relief base—new plates—and I’m running into issues with inconsistent inking. First few pulls—fine. Slowly the ink refuses to sit on certain areas of the plate. (SEE PHOTOS—progression shots) This area changes. I’ve tried switching rollers, changing trucks, taping & untaping rails, changed inks…but with no avail. My 2 thoughts are 1) something is amiss with the plate (but I’ve actually had this happen with other polymer plates or 2) the temp in the studio is affecting the ink consistency and therefore it isn’t taking to the polymer? Anyone?

I’ve already spent the money on the plates, so I’d like to try and work with what I have, rather than purchasing mag. plates.

Thanks! Shelly

Hi Shelly,

I’m really new to this but your post caught my eye because I am also having trouble with inking on boxcar plates (I’ll post this in a new thread). Looking at your photos, it seems to me that the part that is losing ink the fastest is the flower design. Is this true? Maybe the larger surface area of the flowers needs more ink than the text? Maybe it would help to cut the flowers out of the plate and print them separately?

Again I’m new to this but it’s the only thing I can think of.

Looking forward to seeing how this gets resolved!

Karen

Answer me this…

Do you use morgan expansion trucks? If you do that might be the issue. I have had to release the tension in my trucks a time or two and reset my roller height be cause for some reason the become just the slightest bit out of round. Releasing and retightening the trucks helped me to bring mine back into round. I noticed that at a certain point the roller on the right side of my press would align up in a way that the rollers would miss a horizontal band like that.

There might be other causes to you problem but check that along with your other trouble shooting.

cody

Hi guys…I had a similar problem in the past…mine was from using Morgan expansion trucks… the rubber wheels were being ever so slightly mis shapped by the pressure of sitting on the rails. I bought a new pair of plastic trucks from NA Graphics…problem solved.

I’m currently experiencing this exact same problem with so much grief. Every job. Without fail.

Prints fine for up to 30 impressions, then 12 or so bad ones, where they progressively get worse, like your photos here.

I have metal trucks on my rollers. Rollers ink up evenly, and for the good prints, the photopolymer plate is inked evenly.

I’m not convinced the problem is caused by your Morgan expansion trucks (if you have them), because I’ve got metal with the same issue.

HELP!

I’ve got some great jobs coming in soon, but don’t want to spend up to 3 hours more on each job just because of this issue. I’ve tried everything, and the only other thing I think it could be is that my rollers have an ever so slight flat spot.

Roller Bearers save the day!

All three of my C&P presses are lawn ornaments without them. After years of abuse of metal on metal, all of my roller rails are worn wavier than the North Atlantic.

Place a straightedge against yours and you’ll see the problem.

The Morgan trucks only amplify the issue, because they add another level of variability.Taping the rails can help, but the tape will compress mid-run, and it won’t completely level out the rails.

I have experienced the frustration of all of this, so I know exactly what you’re talking about. You add tape, figuring you’re evening the rails. Then, it seems there isn’t enough ink. So you add ink, but it’s splotchy and textured. The rollers are only making contact because they are coated with such a thick layer of ink. Arrgh!

The solution is new Delrin trucks from NA Graphics, and a set of roller bearers which are slightly larger than your form. I have a set that locks up with the job, sitting over the edges of the chase and outside of the printable area.

If you can’t find those, a line of big type locked up on each side of the chase will work in a pinch, but it will result in an inky mess on your tympan.

Roller bearers are wonderful.

If I ever have access to a machine shop, I will start making them out of steel or aluminum L bar. They are virtually a requirement as the presses pass the century-old mark.

It looks like the above folks have offered some good advice on the inking problem… so I won’t rehash what’s already been said.

HOWEVER…. I am very interested in the “Chicken Oscar” dish that is on the reply card. It sounds really tasty. Do you happen to know of any parties that will be serving that dish in the near future? Since you are the printer of the invitations, could you slip me one or two?

Hi Frenchpress,

Have these suggestions solved your problem? I have been having this EXACT same problem. I already use roller bearers. They aren’t helping.

I am going to attach a series of images of my own showing how the disappearing ink moves around the form.

Never had this problem with magnesium plates. But I also never had this problem with polymer plates on the Vandercook … only on my platen presses. On the Pilot the disappearing usually occurs at the edges and I always chalked it up to my taping and untaping the rails. Now on the 8x12 C&P it’s happening all over the form.

My trucks are plastic. My rails are built up with at least 1/8 inch of tape. They started to collect goop and it temporarily helped when I cleaned it off but then the problem again. I wondered if the rollers were skidding across the form but I’ve studied them pretty closely and that doesn’t appear to be the problem Plus if you see the prints it doesn’t really make sense.

I also almost always have a problem where the middle of my forms don’t ink as well as the outside. This happens with and without roller bearers.

help!

print showing top OK low.jpg

print missing ERIC low.jpg

printing missing G and E low.jpg

I have run into the same issue with my Pilot. I’m using the Boxcar Base, photopolymer plates, plastic trucks and composition rollers. I haven’t figured it out either, but I can tell you that if I manually rotate my rollers so a different part hits the plate, the problem is solved for another 20-30 prints before the vanishing happens in a new spot. I thought roller bearers would be the magic solution (haven’t tried them yet), but it sounds like that hasn’t necessarily been the case for others.

I am having this exact same problem - and IT IS SO FRUSTRATING!!!!!!!!!

I just bought roller supports and it hasn’t helped.

I am considering throwing in the towel over this. It’s just so depressing to spend 5 hours printing to get 20 usable prints. Taping the rails doesn’t help, roller supports don’t help, using excess polymer as a bearer helps sometimes but not always.

I don’t know what else to do.

Sounds to me like you might have a dirty roller or even a dirty plate. Try using your type wash to wash your plate and rollers before printing. If you adjusted your rails and your plate is flat then that could be it.

Don’t throw in the towel, Sunlit… buy new rollers. LPS and Susan, noting that your uninked spot changes position, I’d say your rollers are out of round. Replace or recover your rollers and store them properly so this problem doesn’t sneak up on you again.

Good luck!

If the problem appears in different places it can’t be the plate.

It looks like you have a flat spot on one of your rollers — leaving them on the ink disk for more than a few minutes could do it, especially if they’re composition.

Hello everyone,

Thanks for all the replies. As unfortunate as it is that we all have this problem I am so relieved I am not the only one.

Although the flat spot on the roller idea makes sense, I am very skeptical that that is my problem. I never leave the rollers on the ink plate and the rollers on my C&P are practically brand new (rubber). Had this problem from the beginning. In fact I bought new rollers because I was having this problem with the OLD ones (vinylith)! PLUS, I have three rollers! Wouldn’t one of them ink the plate?

Littlemiss, you said to store my rollers properly, should I be taking them off the press when not printing?

And, as I said, I also have a similar problem with my Pilot. Can I really have flat spots on all my rollers?

But I’ll be very interested to know if anyone with this problem solves it with new rollers.

What about humidity? It’s pretty humid in my shop.

THe dirty roller/plate is interesting too except that I often find I have to clean off my press several times before I get the color just right (that is an entirely different problem!) so everything should be clean. I have wondered about solvent residue but I waited a long time before inking the press and printing again last time I cleaned it.

I have loads of magnesium plates that I simply haven’t had the time to use on these presses (fun stuff versus work) so I’ll let everyone know if i have the same problem with them.

Cheers!

PS: I forgot that I had taken off my third roller because I felt it was overinking my form. I do find that if I overink the problem more or less goes away. Obviously that is not ideal because it muddies the image.

So I put back on the third roller and added a tiny bit more ink and at the expense of being slightly overinked I successfully completed my run.

Val

I know it’s hard to believe one roller has a flat spot but it’s entirely possible — and with that much tape on the rails a single roller out of whack could certainly leave an uninked bit.

Assuming you’re printing from the long / left or right edge, the fact that the uninked type skips from spot to spot is almost certainly a symptom of a flat spot.

And if the problem has existed from the beginning, one or more may have been laying flat where they were manufactured, or one may not have been suspended by the cores during shipping.

I’m not an expert and I don’t use expansion trucks or roller bearers or anything like that — so to me the simplest explanation is a flat spot.

Ink your rollers, then take them out of the trucks, and lay a sheet of paper on a flat, smooth surface. Roll each roller over the paper and see what ink turns up — if there’s a band missing, it’s the roller. If they’re all perfectly solid, it’s something else and I’m wrong.

What are these roller bearers and where do I get them for a Craftsman? I am having a similar issue just starting out is very frustrating.

What type of ink are you all using? I hand set type, built forms and ran a C/P back in the 60’s and we never had any problems with coverage. If the rollers are round and the trucks are the same diameter as the rollers, and the impression is sufficient, and the rails are straight, then the only variable is the ink. Remember, we live in the offset age. When Van Son rubber base ink came out, I thought I was in heaven. Wouldn’t have to wash up the platen and the rollers each night. Problem was, the stuff just didn’t adhere well to lead type and even less so to copper. Zinc wasn’t too bad, but we had to add corn starch to the ink to make it short in the summer and use ink saver spray in the winter to get it to pull off the rollers. After a year of this, we went back to oil base ink period. Now I work on letterpresses and I notice that even my customers that just number have consistency problems. I called one today after reading this post. He said that there are, in his opinion, no good letterpress inks available today that perform like the inks back in the 60’s and 70’s.

It may well be that there is something in the ink that transfers to the form and creates a barrier after a period of time. A good way to check is to wash up when the problem starts and start new. if the first pulls are good and then deteriorate again, the only thing that has altered is the ink on the platen. If you are running a light color, add some black or other color to the platen befor you wash and see if the problem goes away. If so, you may have an ink issue. I have many customers that run old ink. I mean REALLY old. Years old! Ink has a shelf life. Ink mfgs tell me an opened can is good for about 2 years max before it has to be re-milled to get the pigments and the vehicle redistributed. I used to have a small mill in Calif. that we used to re-mill older ink, especially if it was a reprint of a PMS color we used and had stored for a long time. Milling made it like new as long as there was no dryer in it. Of course, mills are hard to find now and expensive as well.

As I look at the example above, the flower is blinding. We get the same effect in offset when there is a contaminate in an offset plate. The plate becomes “blind” to the ink. This looks exactly like that problem only in letterpress.. Could there be a chemical in the Poly Plates that is unstable and leaches out during running or under the squeeze of impression?? It seems that the larger areas seem to blind more so than the type. Also, I am not sure about C/P presses, because I have never looked, but I can’t believe that the ink roller stroke from platen to the bottom of the for is such that the same spot on the roller hits the same spot on the form each and every time. This is impossible on a Heidelberg T because the rollers are rotated on the drum each stroke.

The friction of the roller on a C?P platen and the friction of the trucks can’t, in my opinion, be exact enough to make the roller hit the exact same spot every impression. I believe that if it is a roller condition issue, the problem would move around the form instead of staying in the exact same place.

If I was a betting man, I’d say there is an ink issue that no one has solved, or at least no one that has read these topics.

If you want to check your rollers, I do the following:

Pull them out of the press.

Put them on the bed of your, or someone else’ s paper cutter. A marble or granite counter top is good too.

Shine a light from behind the roller.

Get eye level with the counter or table.

Roll the roller back and forth and see if there is light between the table and the roller.

If there is a constant light then the trucks are too big or the roller has shrunk.

If there is a gap between the truck and the table, then the truck is worn, the roller is too large or swollen.

This works in offset to check water rollers (sans the trucks). It should follow for letterpress.

I know this is an old topic, but I wanted to add that I was experiencing some of the same troubles as above. Now, ideally I would run new rollers on my presses, but lately the funds have been hard to come by.

Going from the clue that things would often correct themselves if I cleaned the rails or used a hit from the rosin bag to add friction, I ultimately added a bit more tack to the trucks with a light hit of spray adhesive. What followed was 300 impressions without an issue!

Obviously you should clean the rails after doing this, but if all else fails, try a little DIY tack to give the trucks the friction they need.

James Beard

Vrooooom Press

www.vrooooom.org

Hi James,

So if the tackiness solved the issue for you, do you thinkt he rollers were kind of skidding over the slick surface of the polymer? I see this inking issue is a common one… I experience it every time I print with photopolymer. I have NEVER had it happen with ym handset type or wood mounted mag plates. What adhesive, Super 77?

I am going to try this next time I try print something from a polymer plate I already have. I won’t be ordering any more, however, until I know my press will print the darn things.

Emily (and anyone else with this problem),

There are a lot of things going on when this happens on a press. On one job, the spray adhesive (66 spray adhesive) fixed up everything for me. But, I just finished a hell job that took me nearly 72 hours to print and had nearly every problem listed above and in similar threads and the adhesive didn’t help me. I wanted to share my experience, because there seems to be a ton of threads on this subject, but no definitive answers. I can attest to this, because I spent a lot of time between 3am and 7 am trying to tap the archives here for info. Hopefully this will help someone else.

WHAT I HAVE GATHERED:

The problem is a problem with fundamentals, and comes from a variety of things. Number one, it’s an inking problem. Some threads here suggest rail issues like low spots, out of round trucks, friction on the saddles. Next set of issues includes roller problems like glaze, out of round, hardened rollers, contamination on the roller. Final thing that comes to mind is the inking itself: Is the ink disc warped, is there too much ink, is there too little ink, is the ink drying on the disc, etc. These are all things to check and figure out properly, because the problem will pop up again and again until you find the kink in your system.

So what did I do? I’m not even sure at this point. There’s not a magic solution that I know of, other than time. I lean towards this being an old roller / trucks and roller turning at different speeds issue. I also noticed some greater difficulties with certain inks that I purchase for PMS matches, as opposed to Van Son rubber-base ink. Could be the old “this ink is for offset” type of problem as fewer and fewer ink makers deal with letterpress. That ink was drying on the plate while I was printing.

In other situations, spraying the rails with cleaner and running while wet would solve the problem, only to have it pop up later.

Unfortunately, I don’t think there’s an definitive answer given the number of set ups people have out there, but I do have some advice:

If this pops up and doesn’t seem to resolve, you need to RESET everything related to inking. Keep your chase at first and clean the ink disc. Leave your roller inked. Once this has dried properly, crank the rollers over the ink disc and look at the pattern printed. Notice any breaks in coverage or problems there? Then you’re probably having an issue like the roller not transferring ink, the ink being the wrong type, or the roller just being no good.

Look good on the disc? Cycle the press and let the ink disc ink up again. Try pulling a print? Starting to suspect the rails and height? Remember this: it’s much, much, much easier to set the rails on your platen press if you use a minimum of ink. Why? You’re going to get the sharpest results if you’re just laying a thin layer of ink of the photopolymer. Sure you can set the rails for a heavier coverage of ink, but there’s no repeatability! You would have to be able to achieve the same level of inking every time to match that setting. If you set the rail height exactly, you’ll find that you can ink up this press with a tiny amount of ink, and slowly add to it until the density is right. If you throw on too much ink off the bat, you may be taking yourself on a wild goose chase, and end up blaming everything from the rollers to the rails, to the pope himself.

Once I restarted like this, I was able to reduce my problems from the enigmatic to the mundane, and quickly finished in 3 hours what I had been troubleshooting for the last week. Next job worked just as well. Sometimes I do have issues with plate wiping aka the “disappearing ink”, but when that happens I stop the press, oil the roller ends, clean the rails, wipe the trucks, and use a rosin baseball bag to add some grit to the rails, and I’m back in business.

Sorry there’s no easy answer on this, but remember to take your time and investigate things individually. The scientific method is your best friend when troubleshooting the press, because you want (excellent) repeatability!

About to sleep for half a day,

James Beard

Vrooooom Press

Thanks James! That was an excellent testament to doing the footwork. Sometimes we want the easy fixes, but nothing worth having never comes easy! I’m going to try all of these things if not just to figure out what goes wrong when my press meets photopolymer, but also so that I am better acquainted with the intricacies of my press and the process.

You’ll get it eventually, Emily. Photopolymer doesn’t have much tolerance for bad inking, and I haven’t had a problem that I could blame wholly on the plate. It can be done, and once the above is understood, the next time will be all the more easy. I’m just as guilty of trying to skip ahead to the good part, but this experience is a reminder for me to keep the proper order of setting up my press in mind.

Here is something to think about. It could be the ink is drying on the rollers before getting to the image. Or some think in on the image and the ink is not laying on the image, but wrapping off as the rollers pass.

Hi Frenchpress

I know this is an old thread, but I just wanted to say that I have this problem with both set type and with wood mounted magnesium blocks, so I don’t think it’s necessarily just a polymer issue. I used the machine for well over a year with no problems, then began find that type or areas f blocks would seem to repel the ink. In each case the impression of the uninked area could be seen in the paper - so not a ‘type height’ issue. Thorough cleaning didn’t help either. I think the problem must be with my rollers, trucks or rails, and will try some of the suggestions here.

One other point - just recently I had a whole 70 x 70mm block that wouldn’t ink initially. Again, I could see the impression on the paper and on the packing. I stuck a piece of 700gsm card on the back of the block, and it inked up and was fine for a print run of 80! It seems that the block was of a good height to make a light impression, but not high enough for the rollers.