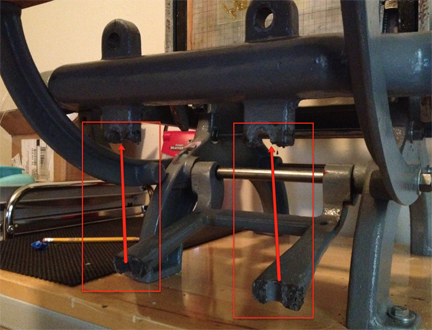

Tabletop Press- broken piece

I need help! My craftsman tabletop press is having issues. When I bought it from a lady in Dallas, this same part broke while transporting it to Houston. The lady told me it had broke on her once before and her husband showed me how to use JB Weld to “weld” it back together. I did that the night I got it home and I’ve been printing with it without a problem ever since. Yesterday I got everything setup and was about to ink up the press when I realized the weld was separating again. I re-welded it and let it sit overnight, taking the platen off to relieve some of the pressure. When I put it back on over 12 hours later, it broke again. I am going to try another type of putty-weld to see if I have better results with that.

If this doesn’t work, I’m not sure what else I can do to fix this. Can I have a new piece cast to replace it? Would that compromise the quality of the machine? I’m at a loss right now and incredibly nervous about how to move forward. I’m new to letterpress, so any words of advice or people who I should contact would be greatly appreciated!

2012-08-06_1320.png

2012-08-06_1321.png

I believe the Craftsman Machinery is still in business, or contact T & T Press Restoration in Minnesota, he may have the part.

You need to have that welded professionally.

I know I’m stating the obvious here but, the JB Weld doesn’t seem like it’s going to work. I wouldn’t have had high hopes for an epoxy anyway.

Anyone in the Houston area know of a welder who can repair cast iron?

Also, how long have you had the press? Is a refund an option at this point? That break was not adequately repaired.

As for parts, Sherwin at Craftsmen is great to work with and might have the part, but you’ll want to check measurements and send pictures as you’re doing so. CMC Pilot clones are pretty various in their designs. I have three and am fairly certain that many parts on each wouldn’t be interchangeable with the corresponding part on the others.

Did the seller tell you that part had been broken when you bought it?

Thanks for the information. I may check into getting it welded then. The epoxy worked for awhile and then just came lose over time. I’ve had it for 5 months now and I bought it from an individual and highly doubt I’d be able to get a refund at this point.

I will check with those options—T&T and Crafsmen as well as a couple local people I know who do welding.

Has anyone had success with welding back parts of their presses?

It’s fairly common — we have several repaired parts on casters at the C.C. Stern Foundry. In fact what you need done is brazing not welding — the broken area ends up being surrounded by nickel alloy which serves to strengthen it. Be sure that the shop really knows how to do it — this is much more difficult than run of the mill welding/brazing.

Brick_Lane, here’s a link to a post I started on a somewhat similar (ongoing) problem:

http://briarpress.org/30378

I’m still visiting welders and looking for someone who is confident they can repair cast iron.

As for the epoxy, anything that works for only a few months only looks like it is working. That’s not really a repair. Any idea what the seller did to cause the break? Drop it? Overstress the press during operation? Crack it while disassembling?

Brazing or a new casting/part is the way to repair this.

In Houston you will find it difficult to get someone that is qualified in a medium to large shop due to the volume of work being produced with the oilfield services industry. If you do find someone, it will most likely be expensive. It is the same with machine shops.

I have found that small shops off the beaten track that work with agriculture are good sources. They are also usually comfortable working with cast iron if they have some older welders. Unfortunately, I have no welder to refer you to, as the guy we have used in the past is deceased and his shop was closed. Maybe around Brenham - you can get some Bluebell ice cream while you wait??

Good luck.

-L

elationpress.com

The technique I’m familiar with for this sort of repair is forge brazing — the part is fluxed and heated in a forge to nearly the brazing temperature, then the repair is made with brazing, and the part is cooled slowly. Heating prevents heat stress caused by heating only the area of the repair, which sets up stresses that will cause future breakage. Brazing fills the entire joint with bonding metal and is very strong, whereas welding is only on the surface around the joint and sets up heat stresses in the cast iron. Find a small shop in the country that does repairs on farm machinery and knows cast iron repair — you should be able to get a good repair reasonably (the guy I used to use in North Carolina would probably have charged about $25 for that repair).

Bob

Brazing has strength because of the build-up of metal on the sides of the break. Because the break goes through the holes that holds the platen bolts, the inside of the bolt hole would have to be machined, which would reduce the metal holding the part together. The break has happened in the one spot that gets the most pressure on the whole press. I think that you are going to need an oven weld to make the parts as strong as possible.

Paul