Shining up bare metal on a press

Hey all,

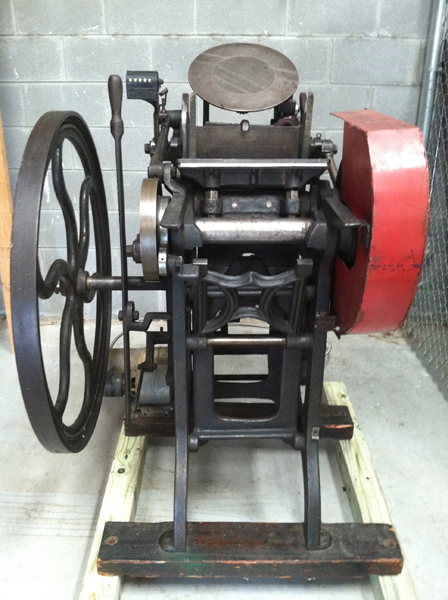

Just moved my new 7x11” Oldstyle C&P into my work space and I’m quite excited. I’ve cleaned her up a bit but was curious about getting a few finishing touches while I wait for the rollers to come in. She’s pretty much dust free and has been oiled, but there are still some sticky grimy parts where old oil has solidified on the bare metal.

I secretly want to re-paint and gild it, but because there wasn’t a speck of rust and I honestly would rather be printing, I’ve nixed that thought. I would still like to shine up the bare metal parts though - like the inking disk, the edge of the fly wheel and some of the metal cross bars. What is the best way to do this?

I’ve seen people wrap the items in paper towels soaked with evaporust, but there isn’t any rust to speak of. Could I get a wire brush attachment for a drill or would that risk pitting the metal? Fine grade sand paper and a pad sander on low? I’ve been scotch brite scrubbing like a wild woman, but man, I don’t have the arm strength for too many hours of that!

(Also, I’ve been looking all over the internet, just haven’t seen anything on how to handle the bare metal, though I’ve seen a lot about stripping paint)

IMG_1033.jpg

Put ink on the disc and it won’t matter :)

409 will degrease the flywheel and not affect the finish.

Cut a stencil and pinstripe to your hearts content on the fly wheel.

Nothing shines antique cast iron better then a brass wire wheel. You need to turn faster then a drill, use a Dremel tool or something similar.

Or just some very, very fine steel wool.

Do not use a wire wheel on the ink disk! It will bite down into the metal and ruin the surface. Use a fine grade of Scotch-Brite (equivalent of 1000 grit steel wool) and Kerosene and just make sure the surface is clean. If you want to polish it use a cloth wheel and jewelers rouge, but that shouldn’t be necessary. You will never be able to get it back to factory specs, and if you try to remove metal it can actually harm the metal. Learn to appreciate the character it has.

Paul

I would avoid the ink disk and fitted parts but it will ad some nice hi-lights to the rest of it.

dog shinny.jpg

Just completing same thing on Adana platen (with one t)and beautiful proof press to be offered on E bay raising money to acquire Mono spares.I have the advantage of fairly big lathe and ditto compressor hence I spun the ink disk in the lathe and polished it with finest grade wet and dry stuck with D.S.A. to large piece of jumbo furniture which is very flat and accurate giving almost up to mirror finish.Next with air driven orbital sander/buffer using progressively finer wet and dry cleaned most of the flat straight surfaces quite nice and fairly speedily especially the bed of the proof press.However in the absence of machinery my unpatened hand held jumbo buffer should perform fairly well by rotating same on the ink disk against the normal rotation for ink distribution. With regard to the straight flat surfaces (generally) El Cheapo DIY reciprocating sander with progressively finer grades of paper will give fairly good good results reasonably quickly even if you have resorted to paint stripper. AND THEN with your newly acquired machine and preparation skills think how you can impress Her indoors with beautiful paint jobs the advantages will be limitless. P.S. re Heidelberg WINDMILL never come across a windmill with only 2 sweeps that works in 2 different planes YET maybe they exist somewhere (deep in the Heart of Texas mayhap) Heidelberg always reffered to them as PLATENS in both sizes with one t. Regards Monotype Mick (mr angry occasionaly)

iron will shine up with a polish/compound used with a cotton buffing attatchment on a drill. To stop further rusting I have used Dinitrol 4010 a clear solvent based sealant over polished steel, but use sparingly or it can slightly dull it, but it stops it rusting……..

I finished my 8X12 early last summer and polished numerous mill finished parts. I polished nonbearing surfaces with a wheel that looks like scotch brite but goes on a 4.5 inch disc grinder, you have to have a light touch but it worked great especially for the flywheel. The round side arms were polished with 3 - 10 inch muslin wheels mounted together on my bench grinder and I used emery compound which gave a soft luster. I removed almost all the paint with a cup brush (wire) on my disc grinder, I had no issue with cutting in to the iron remember cast iron is hard on the surface and it takes lots of time to polish metal.

Polishing cast iron/steel is a labor of love, without a doubt. I believe I have tried most every process of the years. Steel will shine right up if first media blasted then finished with a fine 8” wire wheel turning at about 900 RPM (no swirl marks). Of course the bottom line is keeping it bright so all of that effort is not lost through one season of neglect or moderate humidity. IMHO… paint the iron and polish the steel. Keep the bare steel waxed (paste). The only surface not to wax is the ink disc. The printer’s constant use and cleaning will keep it bright. Scotch Brite is a wonderful product especially on a 2 or 3” Roloc disc. I thank God for rotating power tools.

Tom

tandtpressrestoration.com

Thanks everyone! This has been very helpful. As a second question, the paint job on the press is a bit - chunky. It’s clearly been repainted in the past without completely removing the original paint. It’s chipped off in places exposing small bits of bare metal and isn’t nice and smooth. Should I paint right over it to keep rust from forming? If so with what sort of paint?

try aerosol build primer , it will fill the chips sand back to flat and then overcoat with what you will .

Personally an oily rag wiped over the machine after oiling does me , i do struggle with rust on the bare metal areas as we are seaside here and its grim in the winter !

UK south coast ..