Wash-out-unit D.I.Y.project

Hi, i am working on a project of DIY wash out unit.

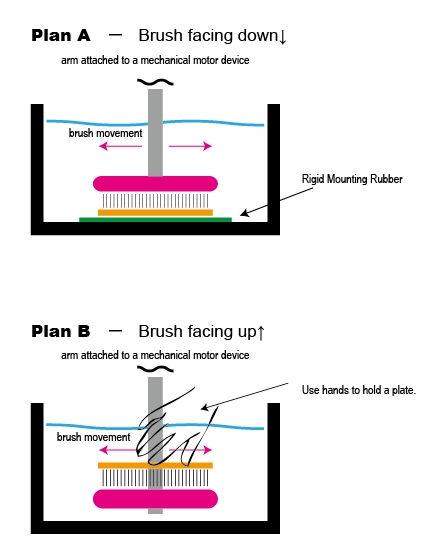

Please check the image attached.

Give me your thoughts and tell me which plan is the better.

The brush is attached to a mechanical motor device.

Plan A —

The brush is facing down. The arm should be adjustable to make sure the brush touch a plate.

I can not find a right material substitute to “Rigit Mounting Rubber from Boxcar”.

If anyone had a good result with kittchin

products or anything else , give me a close up image of the material.

Plan B —

The brush is facing up. I have to use hands to hold a plate.

I can control the pressure of contact surface by hands.

It will be hard to keep a plate flat if a plate is big.

diy-washout-unit.jpg

Couple of ideas.

If you have to hold the plate then that seems to defeat the purpose of having an automatic unit.

If your brush is moving in a circle then the the brush will always be touching the plate in the same place and same direction which might leave areas that don’t get washed out properly. You might want a ramdom orbit kind of action for a mechanical washout unit.

Also, the speed of the brush and the pressure of the brush against the plate will be important to control so as not to damage the image when the polymer is soft during washout.

You know you can get a camel hair shoe shine brush and wash out your plates completely by hand. After you have done a few then you might gain some insight as to how to construct a unit that meets your needs.

Best of luck

The Washout unit on my A&V moves in circles but switches direction every so often. Additionally, the platen is on a lid that flips up, the brush is on four ‘posts’ that are threaded so you can balance the pressure/even out the contact of the brush to the plate, and the water is in a tank that the plate lifts OUT of so that you can dry it briskly after it is done washing.

This is pretty important, you don’t want to leave the material in the water or damp longer than it needs. We use the ‘boxcar method’ of applying a sponge roller to the plate to remove excess water, and then a hairdryer on high air/low heat to quickly dry the plate of any moisture the sponge missed before it goes in the oven.

So I would go with the lower, Option B, if you have a provision to lay the plate out somewhere that it can be dried easily after washout. Option A doesn’t really allow for this, it looks as if the plate is stuck under a tank of water.

Thanks people.

I had good results with Option B.

A shoe cleaning brush is attached to the machine arm for now.

To hold plate, I used Acrylic plate and a reusable gel adhesive sheet. It worked.

IMG_9483.JPG

I thought that washout brushes were made of natural horsehair, but I could be wrong, the do become soft when wet, which would indicate a natural or water absorbing material.

So shoe cleaning brushes are indeed horsehair.

Your test looks good! Where do you get the a reusable gel adhesive?

Enriquevw

The machine sold by Anderson&Vreeland uses the natural horsehair washout brushes. A bit older than the plastic brushes sold on later machines. Also I note that in this thread Boxcar is given credit for the sponge roller. Not true, used long before Boxcar even showed up. There is a history to this all by the way.

Gerald

Hi, enriquevw

The reusable gel adhesive is a Japanese product from Kokuyo, a stationery company.

IMG_9492.JPG

And, I imagine you are in Japan?

enriquevw

Yes I live in Japan.

Those Small Suction Cups really work as handles for an acrylic plate which a photopolymer plate is sticked on with a reusable gel adhesive.

With those handles, I can have control of direction and give some orbital movement as well.

IMG_9512.JPG