Tabletop embossing and depth?

Hello,

Im a new member looking to purchase a tabletop press and seeking some advice. I am interested in creating prints with depth, and I am not convinced that a tabletop press can create a dramatic impression. My budget is about $1000.

I have heard members refer to the depth effect as lettersmashing, or smash printing, but I must admit I am very into that style. I will not be doing large runs or client projects, this press is only for a few small personal projects.

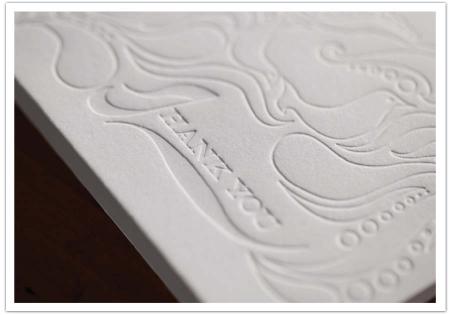

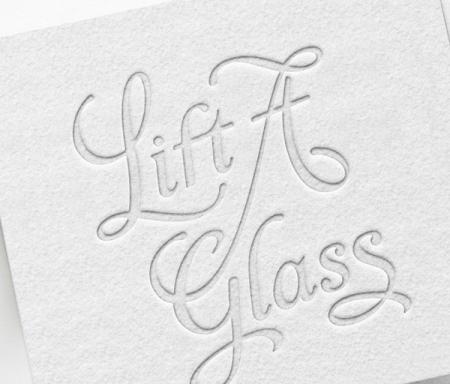

I have researched Adana presses and they are affordable, but I have not seen evidence that they can do what I want. I have attached images of work that has the depth that I am seeking.

Should I stay clear of tabletop presses? Has anyone here achieved depth with a Adana or tabletop press?

Thanks!

Alchemy-Fine-Events-Bridal-Thank-You-Cards2.jpg

1aaa45ebed5274bb23255f029444a339.jpg

I’ll stick my neck out here and say that a table-top platen IS NOT what you are looking for. In general most of them were never designed to create the pressure necessary and most likely will break on you if you sue the amount of pressure you are looking for.

That being said, you would have much better luck with a table-top cylinder press (proof press). The supreme advantage of the cylinder press is that you are not trying to apply pressure the whole image (plate) at once, but instead the pressure is applied incrementally as the cylinder rolls over the form and really applies the maximum amount of pressure only where bottom of the cylinder is as it passes over the form. Pure physics. I hope this makes sense to you.

Instead of trying to crush so many square inches of your form all at once you are simply applying pressure in a rolling motion that passes from one end to the other. The pressure in concentrated in the area directly under the cylinder, providing a better/deeper impression.

Rick

Think of it as a pounds-per-square-inch issue. The platen press has to apply the required pounds per square inch (say it’s 50psi) over the entire surface of the design at the same time (a 4x6 design requires 1200 lbs pressure, which could break the Adana) whereas a cylinder applies the pressure in a narrow band, maybe 1/4 inch wide by the length of the width of the cylinder (maybe 12 inches on a Poco #0 press), so the 50psi is spread over only 3 square inches instead of 24 — or 1200 pounds pressure permits 400psi on 3 square inches. The problem with a cylinder is holding the paper still on the image while rolling the cylinder across it. The cylinder is typically a much stronger structure than the Adana or Kelsey tabletop. A compromise might be a 6x9 Sigwalt Ideal which is strong enough to apply quite a lot of pressure, though not over a 4x6 area. Bottom line, you really should consider a cylinder proof press rather than any platen smaller than a 10x15.

Bob

I’m in the market for a cylinder proof press too.

It would be fantastic if someone could make a list of recommendations.

I’m talking about the likes of a Farley or a Showcard.

Read, listen, hear, respect, and accept the wise advice of those who have said that the small platen press is not designed for the smash printing you wish to do. The cylinder press will better serve your needs.

Rather than the bigger mechanised ones like a Vandercook, Korrex or FAG.

Louis

Look for a cylinder proof press, there are many makes, some a a lot more solidly built than others. Showcard/Line-o-scribes are common, but they have more complex mechanisms and less heavy-duty construction. Nolan and Vandercook made some very solid, hand-pull cylinder presses.

Bonus is that these presses not only do the stuff you are looking for better, on bigger formats, but also that on average these cost about half as much as a tabletop.

Hi Orion J.

looking at your sample pictures I’m thinking that you might want to consider using a hot foil stamping press instead of a letterpress. The heat coming through a metal hot foil stamping die is going to make a really nice smooth emboss or deboss and the magnesium dies can be made with a broad shoulder that catches the light. They can also make you a fiberglass counter die that will push the paper into the image on the die to make it really sharp and deep.

also hot stamping presses are generally built very robust and/or use an up-down motion (for small hand fed machines anyway) so the strength or weakness of the press wouldn’t be ann issue.

best of luck

Bruce

Thank you all for responding. I feel like this forum is brimming with wisdom and I value all of your advice. I clearly have a lot of research to do and I am looking forward to trying out a cylinder press. I have certainly turned my attention away from the tabletop platen presses.